- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Precision

-

Model Number:

-

1/8"-4" cap

-

Name:

-

Elliptical Head/Dished Heads End Cpas Tank Head /Tube End Caps

-

Type:

-

Flange, dish head,end cap

-

Punching hole:

-

according to the drawings

-

Color:

-

Black/Grey

-

Test:

-

Ut,Rt,Mt,PT,Et

-

Surface treatment:

-

sand blasting and antirust treatment

-

Feature:

-

Stocked

-

Production:

-

hot/cold pressing

-

Usage:

-

Water Tanks / Dish End / Pipe Cap,Oil, Chemical Industry, Water tank

Quick Details

-

Technics:

-

Forged

-

Shape:

-

Water Tanks / Dish End / Pipe Cap

-

Head Code:

-

Water Tanks / Dish End / Pipe Cap

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Precision

-

Model Number:

-

1/8"-4" cap

-

Name:

-

Elliptical Head/Dished Heads End Cpas Tank Head /Tube End Caps

-

Type:

-

Flange, dish head,end cap

-

Punching hole:

-

according to the drawings

-

Color:

-

Black/Grey

-

Test:

-

Ut,Rt,Mt,PT,Et

-

Surface treatment:

-

sand blasting and antirust treatment

-

Feature:

-

Stocked

-

Production:

-

hot/cold pressing

-

Usage:

-

Water Tanks / Dish End / Pipe Cap,Oil, Chemical Industry, Water tank

Stainless Steel Elliptical Head/Dished Heads End Cpas Tank Head /Tube End Caps For Boiler Pressure Container

We specialize in the fabrication of conventional tank heads, from carbon, alloy, and low alloy steels, stainless clad,titanium, nickel, Aluminum and SA516 grade 70 carbon steel. Our products are primarily intended for use as pressure vessels, tanks, and boilers, and manufactured to all applicable GB, ASME, DIN, and GOST standards.

Tank heads can be fabricated in configurations such as, dished or flanged only, standard flanged and dished, ASME flanged and dished, or ASME 2:1 semi elliptical. We possess the welding capabilities to accommodate almost any design or applicable standard, our certified welders and advanced welding equipment are prepared to provide stick-electrode, semi-automatic, gas shielded, and submerged arc welding. Manufacturing seamless tank heads from 6" up to 260" in diameter, in thicknesses from 3/19" to 15", with various prepped edges, such as trimmed, untrimmed, beveled, or tapered. We also offer stress relieving and blasting services including post weld heat treating, normalizing, and annealing. A wide array of specialized testing is also available, with full test data reporting.

| DN | Straight edge | Gradient | Tolerance of total depth(height) |

| DN≤2000mm | h=25mm | outer:1.5inner:1.0 | (-0.2~+0.6)%DN |

| DN≥2000mm | h=40mm | outer:2.5 inner:1.5 | (-0.2~+0.6)%DN |

| Others |

outer:6%h &≤5 inner:4%h &≤3 |

(-0.2~+0.6)%DN |

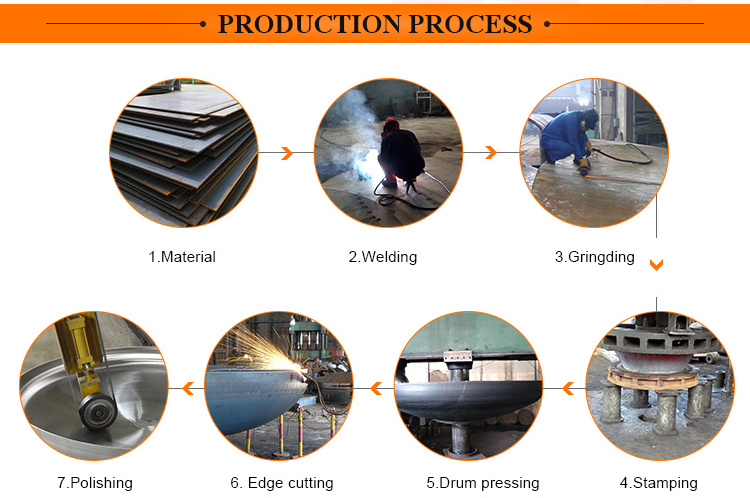

Production Process of Heads:

Picking steel---Cutting---Welding---Heating---Spinning---Stamping---Trimming---Defect detection---QC---Warehousing---Transporttation

♦ Small order advantage, flexibly in dealing with orders;

♦ Quality: Strict control of raw materials and the production process;

♦ Advanced technology,best quality,customer satisfaction,reputation first,good after-service;

♦No cracks , delamination, inclusion ,and other defects;

♦ We provide the best service based on professional and sincerely attitude.

1, Shipment by bulk OD more then 5000mm

2, GP Containers for OD within 2200mm

3, FR Container OD within 4000mm

4, Iron Cage and wooden pallets accordingly.

1. What’s the information should I provide when inquiry?

Thanks for your question. If you have drawings, we will be entirely in accordance with production drawings . If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head( We have elliptical head, hemispherical head, dished head, flat head, etc. ),diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

2. what are surface treatment of the product?

Thanks for your question. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

3. How do you ensure the quality of products?

Thanks for your question.Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

4. Can you help us matching related products?

Thanks for your question. Our company also is surrounded by a lot of ancillary businesses, such as flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices .