- Product Details

- {{item.text}}

Quick Details

-

Colour:

-

White

-

Viscosity:

-

Paste

-

Properties:

-

Water Proof , Heat Proof , Acid Proof

-

Density:

-

1.65 gm/ccg

-

Curing:

-

48 hrs. @ 25 - 30 C

-

Type:

-

Wall Coating

-

Function:

-

Waterproof, Moisture-Proof, Heat Insulation

Quick Details

-

CAS No.:

-

not assigned

-

Place of Origin:

-

Rajasthan, India

-

Certification:

-

ISO 9001:2008

-

Colour:

-

White

-

Viscosity:

-

Paste

-

Properties:

-

Water Proof , Heat Proof , Acid Proof

-

Density:

-

1.65 gm/ccg

-

Curing:

-

48 hrs. @ 25 - 30 C

-

Type:

-

Wall Coating

-

Function:

-

Waterproof, Moisture-Proof, Heat Insulation

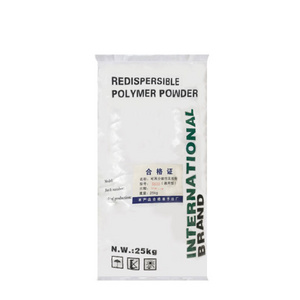

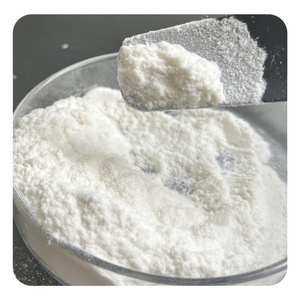

Putty is advanced Wall Care Polymer Putty . After coating on Plaster Wall it gives a laminated white smooth surface which appears like mirror polished marble . It gives grace to Plaster . It can also be applied on metal & wooden surfaces.

Performance Features & Benefits :

- Water Proof

- Heat Proof

- Anti Bacterial

- Anti Fungal

- Washable

- Silky Finish

- Maintenance Free

- Enhance the beauty of Expensive Paints

- Provide best value for money

- Reduces paint consumption up to 25%

- Highly durable

This is paste like white polymer emulsion product. A smooth film with funner patti can be applied like putty on any surface. Plastered walls can be made laminated white or colored, smooth surface which appears like mirror polished marble. In addition to giving grace to plasters it protect walls from water, fungal, bacteria etc. A thermal barrier is made with acid resistance surface . It is a brand new concept and is replacement of kaudi plaster (Irish work) of olden forts. That was costlier but this is superior in properties appearance and easy to be done, say user friendly. In old days this kind of finish was done in forts by kings only. Now middle class people can afford to get it done. This is also a replacement of putty (cement/lime based) but much superior quality product and accordingly cost is higher. The advantages are much more and products is ultimate economical. In recent past we were required to remove cement/lime based putty from many building and replaced by our laminate. This was necessary because cement based putties gets cracked/swollen due to humidity or dampness resulting in cracks blistering, damage to paints, peeling of paints etc. The efforts required to remove earlier coated putty costed heavily to the owner of residents. Cement/lime based putties are being used in mass scales but proportionately above kind of suffering is also going on.