- Product Details

- {{item.text}}

Quick Details

-

Raw material:

-

soybean,corn,rice bran

-

Name:

-

soybean extruder machine

-

Capacity:

-

40-2000kg/h

-

Advantage:

-

High Efficient

-

Color:

-

Client's requirements

-

Feature:

-

High Efficiency Low Cost

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Related machine:

-

Dryer,Mixer,Flavouring Machine

-

Processing Types:

-

Poultry Feed Mill Plant Cost

-

Application:

-

Poultry Farm

-

Certification:

-

CE ISO SGS

Quick Details

-

Place of Origin:

-

Hebei, China

-

Weight:

-

800 kg

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Raw material:

-

soybean,corn,rice bran

-

Name:

-

soybean extruder machine

-

Capacity:

-

40-2000kg/h

-

Advantage:

-

High Efficient

-

Color:

-

Client's requirements

-

Feature:

-

High Efficiency Low Cost

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Related machine:

-

Dryer,Mixer,Flavouring Machine

-

Processing Types:

-

Poultry Feed Mill Plant Cost

-

Application:

-

Poultry Farm

-

Certification:

-

CE ISO SGS

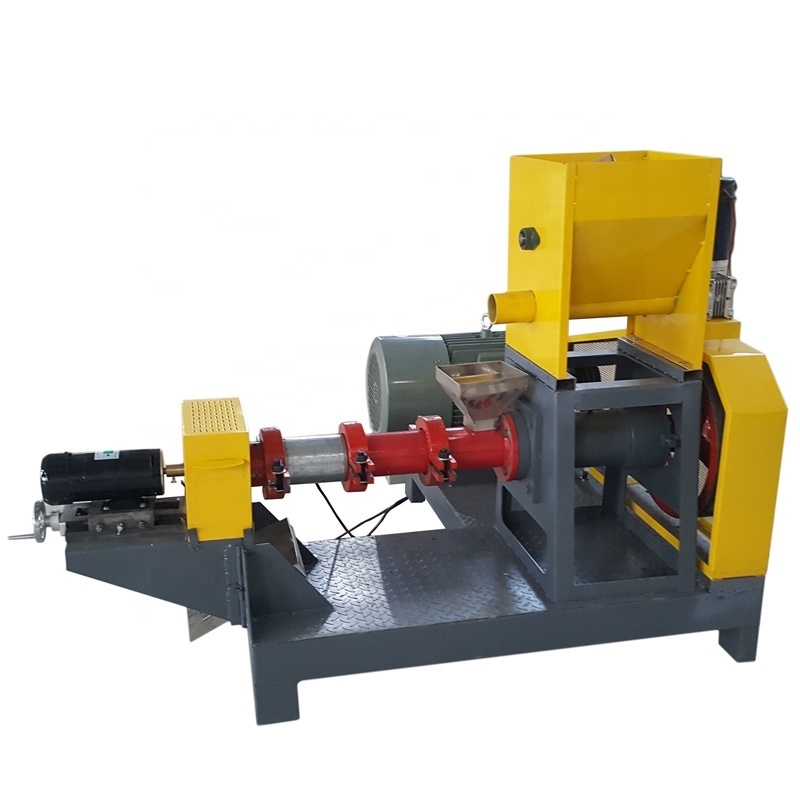

Soya bean/rice bran animal feed soybean extruder for sale

T he soya bean extruder machine is designed to bulk soya,corn for animal feed making w ith high protein , widely used as source of protein in animal diets, including pig, chicken, cattle, horse, sheep, and fish feed. It is widely used in soybean, maize,soybean

meal, cottonseed meal, rice bran and other raw materials.

Feature:

1. High temperature and pressure can effectively kill the bacteria and detoxicate, changing the nutrition resistant factor, lowering the degradation of nutrients, improving the digestibility of protein and starch.

2. Screw and barrel are designed optimized to get longer service life and lower production cost.

3. N ovel design, high output, stable operation, the main components is heat treated special alloy material refined, with a high degree of wear resistance and long life .

Working Principle

soybean extruder consists of driving system, feeding device, extruding device, an d electric control cabinet etc . This machine can transfer mechanical energy to thermal energy by extrusion, friction and shearing function of non-equidistance screw extrusion system, and form a certain pressure and temperature in the extruding chamber .

| Model | Capacity(kg/h) | Main Power(kw) | Feed Power(kw) | Cut Power(kw) | Screw Dia(mm) |

Pelletsize (mm) |

| DGP40 | 40-60 | 7.5 | 0.4 | 0.4 | Φ40 | 1-12mm |

| DGP50 | 60-80 | 11 | 0.4 | 0.4 | Φ50 | 1-12mm |

| DGP60 | 100-150 | 15 | 0.4 | 0.4 | Φ60 | 1-12mm |

| DGP70 | 180-250 | 18.5 | 0.4 | 0.4 | Φ70 | 1-12mm |

| DGP80 | 300-350 | 22 | 0.4 | 0.6 | Φ80 | 1-12mm |

| DGP90 | 400-450 | 37 | 1.1 | 0.6 | Φ90 | 1-12mm |

| DGP120 | 500-700 | 55 | 1.1 | 1.5 | Φ120 | 1-12mm |

| DGP135 | 800-1000 | 75 | 1.1 | 2.2 | Φ133 | 1-12mm |

| DGP160 | 1200-1500 | 90 | 1.5 | 2.2 | Φ155 | 1-12mm |

| DGP200 | 1800-2000 | 132 | 1.5 | 3.0 | Φ195 | 1-12mm |

Wet type extruder