- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Retain

-

Voltage:

-

380V CUSTOMIZED

-

Dimension(L*W*H):

-

720*720*950MM

-

Weight (KG):

-

83 KG

-

Power (kW):

-

0.75

-

Name:

-

Plastic Vertical Color Mixer Machine

-

Raw material:

-

PVC PE WPC ABS PC

-

Type:

-

Plastic Material Mixer Machine

-

After-sales Service Provided:

-

Online Video Technical Support

-

Keywords:

-

Plastic High Speed Mxier

-

Product name:

-

High Speed Mixer Unit

-

Suitable for:

-

Raw Plastic Material Mixing

-

Usage:

-

Mixer Equipment

-

Function:

-

Mixing Plastic Raw Material

-

Mixer type:

-

Vertical Mixing

Quick Details

-

Capacity (kg):

-

100kgs

-

Output (kg/h):

-

25 - 1000 kg/h

-

Application:

-

Injection /Extruder Machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Retain

-

Voltage:

-

380V CUSTOMIZED

-

Dimension(L*W*H):

-

720*720*950MM

-

Weight (KG):

-

83 KG

-

Power (kW):

-

0.75

-

Name:

-

Plastic Vertical Color Mixer Machine

-

Raw material:

-

PVC PE WPC ABS PC

-

Type:

-

Plastic Material Mixer Machine

-

After-sales Service Provided:

-

Online Video Technical Support

-

Keywords:

-

Plastic High Speed Mxier

-

Product name:

-

High Speed Mixer Unit

-

Suitable for:

-

Raw Plastic Material Mixing

-

Usage:

-

Mixer Equipment

-

Function:

-

Mixing Plastic Raw Material

-

Mixer type:

-

Vertical Mixing

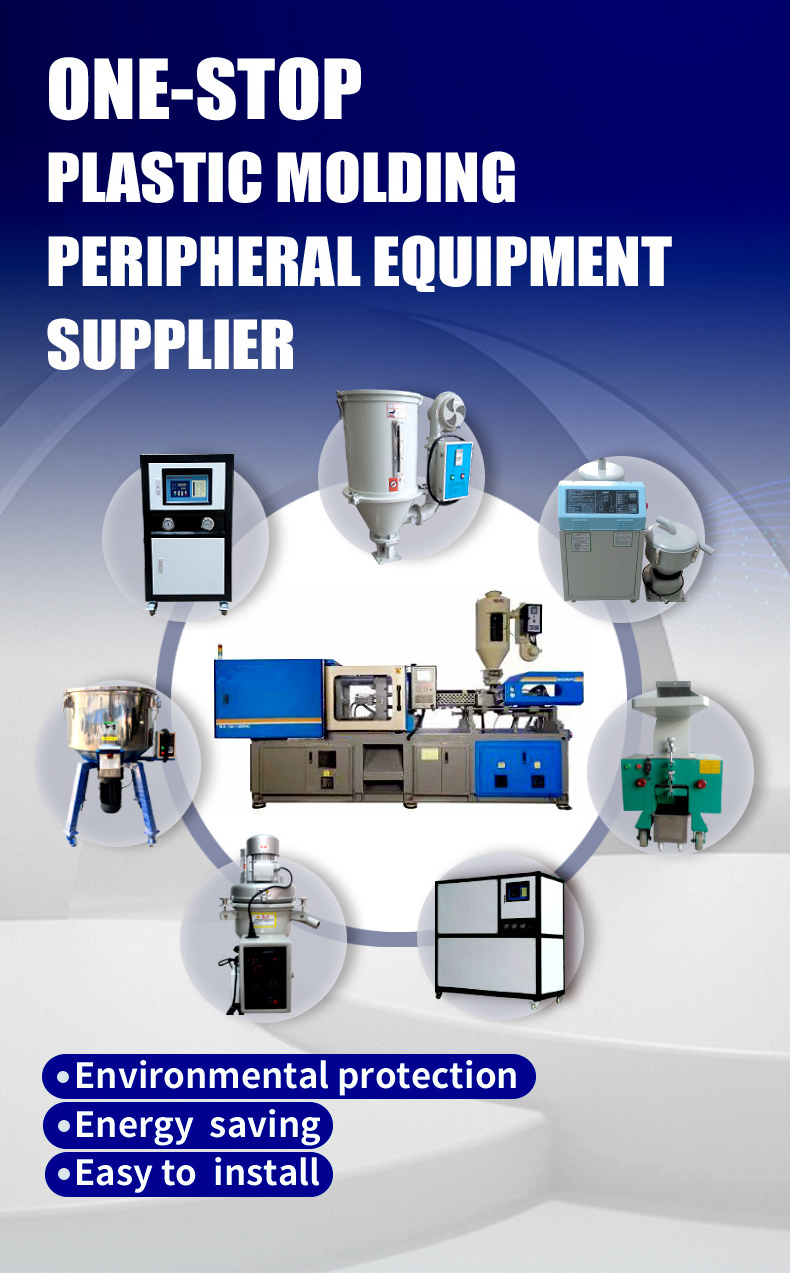

More than 20 years of

Professional E

xperience !

Specialized in

the production of Plastic Crusher , Hopper Dryer, Loader,Vertical Mixer,Industry Chiller,Conveyor Belt and so on-----

Plastic Auxiliary Equipment Factory

Production Photos

Vertical Color Mixer

Vertical color mixer features:

1, The use of high-quality stainless steel material, high strength, easy to clean, avoid corrosion;

2, Four-wheel upright design, small volume, easy to move; 3, with cycloidal reducer motor, low noise, durable;

4, In a short time to complete uniform mixing, low energy consumption, high efficiency;

5, Bucket cover, bucket bottom stamping forming, with accurate, more durable;

6, Mixing time can be set according to demand, self-stop.

2, Four-wheel upright design, small volume, easy to move; 3, with cycloidal reducer motor, low noise, durable;

4, In a short time to complete uniform mixing, low energy consumption, high efficiency;

5, Bucket cover, bucket bottom stamping forming, with accurate, more durable;

6, Mixing time can be set according to demand, self-stop.

Operational Matters

1. Oiling the bearings and gears of the machine regularly to maintain lubrication.

2. Regularly check whether the belt is slack, and the motor should be transferred outward until the belt is pulled tight.

3. It is strictly prohibited to reach into or rotate the machine when it is running.

4. The power supply must be turned off when cleaning or repairing.

5. It is strictly prohibited to exceed the rated weight. Dust impurities in the hopper must be thoroughly cleaned before color mixing.

2. Regularly check whether the belt is slack, and the motor should be transferred outward until the belt is pulled tight.

3. It is strictly prohibited to reach into or rotate the machine when it is running.

4. The power supply must be turned off when cleaning or repairing.

5. It is strictly prohibited to exceed the rated weight. Dust impurities in the hopper must be thoroughly cleaned before color mixing.

6. Click before color mixing to ensure that the machine is turned on and used under no abnormal circumstances.

7. The power supply should be turned off after the end of color mixing.

8. If there is any fault in the mechanical operation, it must stop and cut off the power supply before processing.

9. Before running the machine, check whether the screw of the pulp blade in the barrel is loose. If it is loose, it should be

tightened.

10. Do not mix tools, hard objects or belts into the bucket.

7. The power supply should be turned off after the end of color mixing.

8. If there is any fault in the mechanical operation, it must stop and cut off the power supply before processing.

9. Before running the machine, check whether the screw of the pulp blade in the barrel is loose. If it is loose, it should be

tightened.

10. Do not mix tools, hard objects or belts into the bucket.

Production Details

ADJUSTABLE BUCKLE

The buckle has good sealing and convenient operation

ARGON ARC HANDLE

Welding firm, no burr, durable

Blade thickening and widening, reasonable structure design, stirring faster,

360℃ dimensional mixing sheet, multiple thickened blades, large cover area in the barrel, efficient and uniform mixing

THICKENED STAINLESS STEEL BARREL

Standard 201 stainless steel polishing cylinder, easy to clean, wear and corrosion resistant.

MECHANICAL TIMER

1-30 minutes regular shutdown time, stirring raw materials without waiting, energy saving, the use of rest assured

DUST AND SPLASH PROOF BUCKET COVER

Open the lid to stop stirring, prevent particles from splashing, and keep the production workshop clean

Production Specification

|

Plastic Pellet Mixer Specification

|

|

|

|

|

|

|

||||||

|

Model

|

Power

|

|

Capacity(KGS)

|

Rotate Speed(R/MIN)

|

Measurement(mm)

|

Weight

|

||||||

|

|

KW

|

HP

|

25

|

85

|

|

|

||||||

|

RT-25

|

0.75

|

1

|

25

|

85

|

720*720*950

|

83

|

||||||

|

RT-50

|

1.5

|

2

|

50

|

85

|

830*830*1120

|

125

|

||||||

|

RT-100

|

3

|

4

|

100

|

85

|

1000*1000*1280

|

180

|

||||||

|

RT-150

|

4

|

5.5

|

150

|

85

|

1130*1130*1380

|

270

|

||||||

|

RT-200

|

7.5

|

10

|

200

|

85

|

1200*1200*1490

|

315

|

||||||

|

RT-300

|

7.5

|

10

|

300

|

85

|

1200*1200*1700

|

380

|

||||||

|

Remark: Color, size, voltage, customer requirements can be customized.

|

|

|

|

|

|

|

||||||

Zaozhuang Retain Manufacturing&International Trading Co.,Ltd

Introduction

Our company is a leading manufacturer in China with more than 20 years of professional experience.Specializing in Plastic Auxiliary Machinery, Refrigeration and Cooling Equipment, Agricultural Equipment, Take-up Machine and Shears,Bends ,Rolling Machines. The company has set up three factories in Guangzhou, Zhejiang and Jiangsu.We have a professional R & D team and after-sales team, which can fully meet the requirements of different customers, and we will immediately solve the customer feedback problems. our products exported to United States,Italy,Russia,Japan, European countries and are widely praised by global clients

.

FAQ

Are you manufacture?

Sure, We are one of leading manufacturers with 20 years of professional experience in China

Do you have Stock productions to sell?

Yes,it is .But we also offer OEM/ODM service. Please send us your request if you are interested.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20years production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process.

Hot Searches