- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Havesino

-

Voltage:

-

AC 380V/220V. 50/60HZ

-

Dimension(L*W*H):

-

1800MM*1700MM*1450MM

-

Weight:

-

1500 kg

-

Marketing Type:

-

Hot Product 2024

-

Warranty of core components:

-

2 Year

-

Key words:

-

Easy To Operation

-

Advantage:

-

Econmical

-

Application:

-

Thermal Paper

-

Max cutting width:

-

900mm

-

Speed:

-

200m/min

-

Usage:

-

ATM/Cash Register/Fax/Lottery paper

-

Certification:

-

CE Certificate

-

After-sales Service Provided:

-

Engineers Service Machinery Overseaside

-

Warrantty:

-

2 years

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

200 m/min

-

Max. workable width:

-

900mm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Havesino

-

Voltage:

-

AC 380V/220V. 50/60HZ

-

Dimension(L*W*H):

-

1800MM*1700MM*1450MM

-

Weight:

-

1500 kg

-

Marketing Type:

-

Hot Product 2024

-

Warranty of core components:

-

2 Year

-

Key words:

-

Easy To Operation

-

Advantage:

-

Econmical

-

Application:

-

Thermal Paper

-

Max cutting width:

-

900mm

-

Speed:

-

200m/min

-

Usage:

-

ATM/Cash Register/Fax/Lottery paper

-

Certification:

-

CE Certificate

-

After-sales Service Provided:

-

Engineers Service Machinery Overseaside

-

Warrantty:

-

2 years

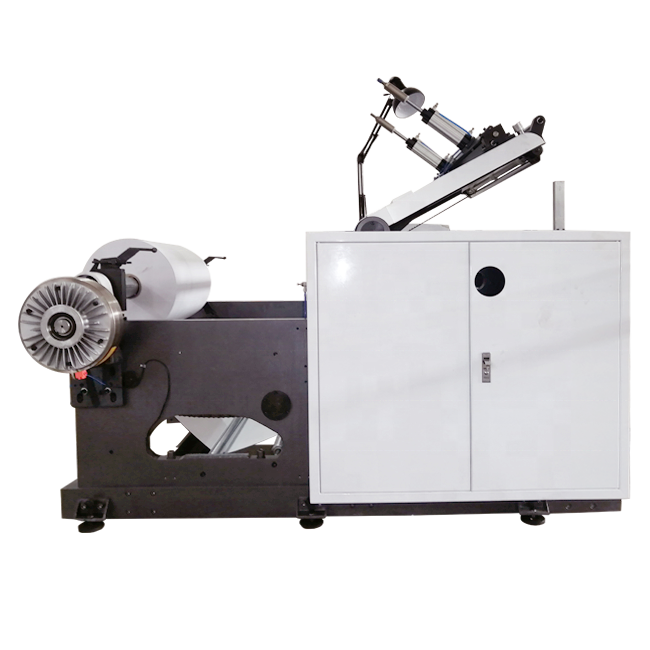

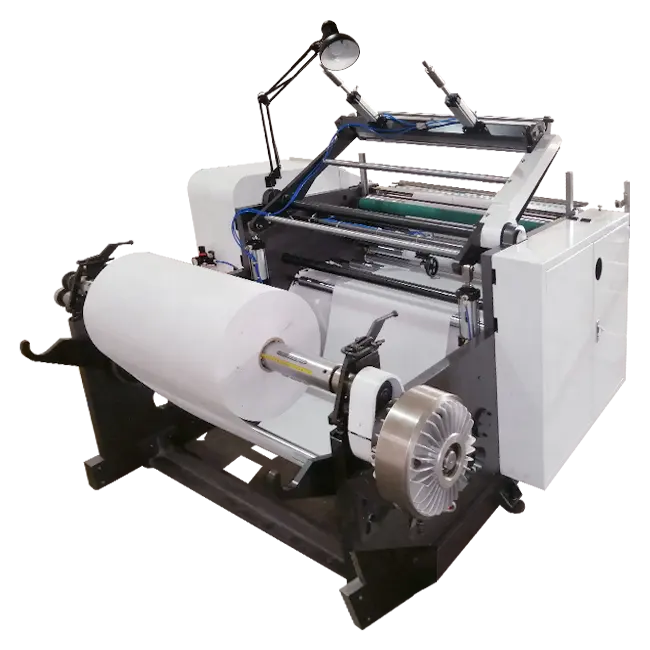

Commercial Used Phenol Free Thermal Receipt Paper Rewind Cutter POS ATM Receipt Paper ECG NCR Medical Paper Rewinder

Introduction:

POS ATM Receipt Paper Rewinder CP-S900C is a very versatile and professional slitter which could handle a wide range of paper widths and thicnesses. This machine can slit the thermal paper jumbo roll into smaller specific width and then rewind them into small paper rolls with certain size like 57mm,79mm,80mm and other hot selling thermal paper roll sizes on the market.

Applications:

CP-900C is a very precise and cost effective thermal paper roll slitting rewinder for Thermal paper rolls,Lotery rolls, POS rolls, Cash register rolls, Medical paper rolls, Gas pump paper rolls, Plotter rolls, ECG paper rolls and so on. It's a cheap but very smart thermal paper slitting and rewinding machine.

Main Configurations:

- This bond paper slitting rewinder equipped with Panasonic PLC and Weinview touch screen,all the parameter are display on the monitor.

- Auto Tension Control System for unwinding tension.

- Meter Counter, the data displayed on the screen.

- Synchronic Belt,used to avoid the over lap problem.

- Frequency Inverter for main inverter motor driving, the speed can be displayed on the operation panel.

- All the transmission rollers have been dynamic/static treated.

- Emergency switch.

- EASY SETTING ON THE TOUCH SCREEN

- EASY TENSION SET

- WITH END MARK ROLLERS TO MAKE END MARK ON THE INSIDE OF THE ROLLS

- WITH METER COUNTER WHEEL,TO MAKE SURE THE MACHINE CAN STOP AUTOMATICALLY AT SETTING METER

Basic specification:

| Model | CP-S900C |

| SLITTING LAYER | SINGLELAYER |

| SLITTING WIDTH | 900MM |

| SLITTING THICKNESS | 40-120GR/M2 |

| UNWINDING DIAMETER | 1200MM |

| UNWINDING TYPE | AIR SHAFT |

| UNWINDING CORE SIZE | 3 INCH |

| UNWINDING BRAKE TYPE | MAGNETIC POWDER BRAKE |

| REWINDING WIDTH | 20MM(MIN) |

| REWINDING DIAMETER | 250MM(MAX) |

| REWINDING SHAFT | 8-50MM |

| SLITTING UNIT | 10PCS CIRCLE BLADE |

| WALL THICKNESS | 30MM |

| MECHANICAL SPEED | 200M/MIN (MAX) |

| WORKING SPEED | 180M/MIN (MAX) |

| POWER SUPPLY | 380V,3PHASES, 50Hz, 2.2KW |

| AIR POWER SUPPLY | 0.8 Mpa (MINI) |

| N.W | 1500 KG |

| MACHINE SIZE | 1800MM*1700MM*1450MM |

| WOODEN BOX SIZE | G.W. | N.W. | H.S CODE |

| 215*186*160CM | 1600KGS | 1550KGS | 8441100000 |

1. ONE YEAR GURANTEE FOR THE KEY PARTS OF THE MACHINE, THE PARTS ARE AS FOLLOWING:

MOTOR, PLC, TOUCH SCREEN,MAGNETIC POWDER CLUTCH

2. MACHINE INSTALLING AND WORKER TRAINNING SERVICE.

A. ENGINEER AVAILABEL ON YOUR FACTORY TRAINNING AND INSTALLING

IF YOU PAY THE VISA COST, AIR TICKET, FOOD, HOTEL AND SUBSIDY.

B. TRAINNING YOUR WORKER AT OUR FACTORY SERVICE IS AVAILABEL

YOU ONLY NEED TO PAY THE HOTEL COST.

3. WHOLE LIFE TECHNICAL SUPPORT, 24 HOURS BY 7 DAYS CALLING-SERVICE.

WE GUARANTEE FULLY TEST AND CHECK BEFORE SHIPMENT TO ENSURE THE QUALITY.

A.:We pay much attention to quality control from the very beginning to the very end. Fully check and test takes before shipment.

Q.:Where is your factory located? How can I visit there?

A.:Our factory located at Hangzhou,China.You can fly to Hangzhou airport directly or take fast train from Shanghai. We will arrange to pick you up from train station or airport.

Q.:What’s service or guarantee can you offer?

A.: One year guarantee for key parts of machine;Machine installing and worker training service; Free technical support whole life; Material support

Q: Will it take long time to receive the machine?

A: The lead time will be 7 days after the pre-payment has been issued. We will help to deliver the machine at the earliest.

Q:Why do I choose your machine?

A: Our machine is cost-effective and lifetime technical support. We have random complaints from the older order client. The goal of our company is to offer the client the most valuable products and make a win-win result.

Q. Without professional technicians, do not know how to choose a machine?

A: Our staff is all professional, if you don't know how to choose a machine, we can help you select the most proper machine for you.

Q. Do not find the right machine structure to match your current demand?

A: You can tell us what's your requirements about the machine, we support customization for you to meet your demand and we will provide full sets of solutions for you. We guarantee to solve all your needs, all you need to do is trust us and tell us your needs.

Q.Don't have a professional operator to run the lines?

A: We shipped our machine as a whole, and it is very easy to everybody to operate it, we send all manuals and videos and 7*24 hours service to you. Everybody will learn it in 2 hours.