- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

380V-50Hz 3 Phase 4 Wire

-

Dimension(L*W*H):

-

1510 1100 1610

-

Weight (KG):

-

420

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Dry Air Generator

-

Air supply pressure:

-

0.05~0.5 MPa

-

Working pressure:

-

0.6 ~ 0.8 MPa

-

Dew Point:

-

≤ -60 ~ -70℃

-

Noise:

-

60 ~ 80 dB (A)

-

Continuous working time:

-

≥ 200 h

-

Inlet Air Temp:

-

≤ 50℃

-

Filtration Accuracy:

-

0.01 Micron

-

After-Sales Service Provided:

-

Field Installation, Commissioning and Training

Quick Details

-

Type:

-

Dry Air Generator

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

FUOOTECH

-

Voltage:

-

380V

-

Power:

-

380V-50Hz 3 Phase 4 Wire

-

Dimension(L*W*H):

-

1510 1100 1610

-

Weight (KG):

-

420

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Dry Air Generator

-

Air supply pressure:

-

0.05~0.5 MPa

-

Working pressure:

-

0.6 ~ 0.8 MPa

-

Dew Point:

-

≤ -60 ~ -70℃

-

Noise:

-

60 ~ 80 dB (A)

-

Continuous working time:

-

≥ 200 h

-

Inlet Air Temp:

-

≤ 50℃

-

Filtration Accuracy:

-

0.01 Micron

-

After-Sales Service Provided:

-

Field Installation, Commissioning and Training

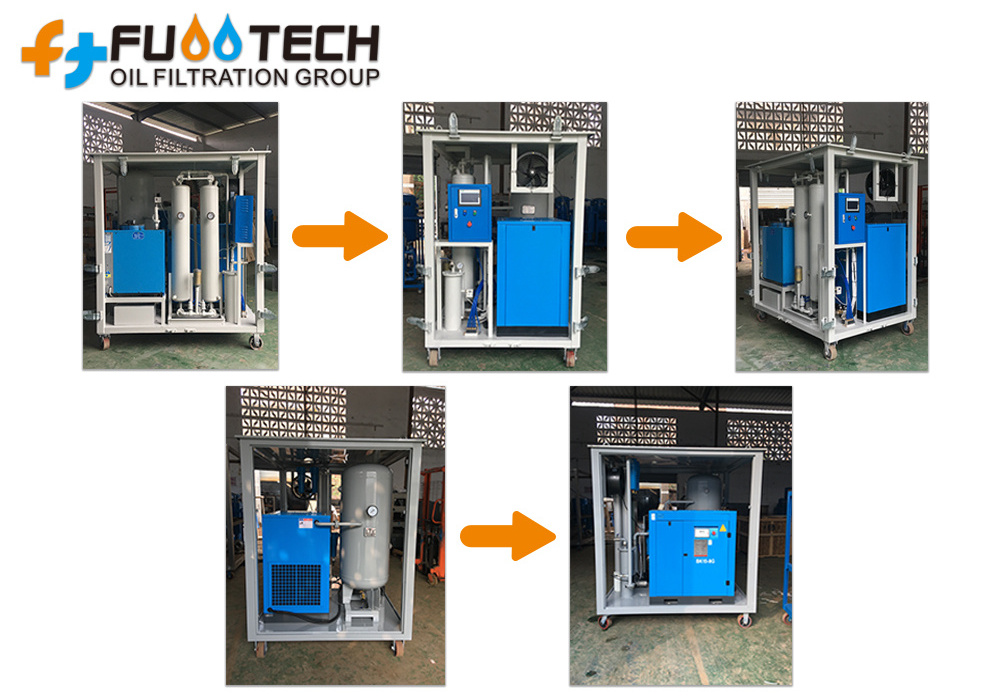

Factory Price DAG-400 Compressed Air Dryer For Transformer Substation Maintenance

The c

ompressed dry air generator

is suitable for providing dry air with low dew point during the installation or maintenance of transformers, reactors and other equipment. The dry air it provides can remove moisture and impurities in the gas, ensuring that the internal insulation materials of the power equipment will not be damp, and the staff will not suffocate due to lack of oxygen when working inside the equipment. Compared with using nitrogen, dry air is safer, more reliable, more economical and more convenient. When using a dry air generator for equipment maintenance, it will not be affected by changes in external climate conditions; especially for overnight operations, you only need to seal the flanges and fill the dry air to 0.02MPa ~ 0.03MPa.

Compressed Dry Air Generator

Working Principle:

DAG series

compressed dry air generator

is mainly composed of screw air compressor, air storage tank, cold dryer, adsorption dryer, air filtration system, PLC intelligent liquid crystal display control system and other parts. The atmosphere first passes through the screw air compressor to compress the air and then enters the air storage tank and dehydration filter, and the air is dried for the first time; the compressed air then enters the cold dryer and filter, most of the water vapor is condensed into ice water, and the air is dried for the first time Secondary drying; then enter the adsorption dryer for the third drying to completely absorb the remaining water vapor; finally, after being filtered by a high-precision filter, the dry air with low dew point and high purity is sent to the equipment that needs dry gas.

Spare Parts

|

Spare part name

|

Quantity

|

|

Air supply enhancement tube

|

20m

|

|

Special tools

|

1 set

|

|

Dust removal gun and pipe

|

1 set

|

|

Hoop

|

4

|

|

Instruction Manual, Certificate of Conformity and Packing List

|

1 each

|

Technical advantages

☆

Integrated modular design. DAG series dry air generator adopts modular design and integrates international leading air drying technologies such as compression, refrigeration and adsorption. It has good effect and is convenient to use and maintain.

☆ Adsorbent regeneration method. The adsorbent of the DAG series dry air generator adopts a non-thermal pressure difference automatic regeneration method, which automatically dries the adsorbent while the equipment is running; it does not need to dry the adsorbent like ordinary dry air generators And affect the site operations and construction period. ☆ The dew point of finished gas is low. The core index to measure the dry air generator is the supply air dew point, the lower the dew point, the drier the air. Dry air with a low dew point will absorb moisture inside the transformer to improve insulation performance. DAG series dry air and compression drying, freeze drying and adsorption drying are integrated and adopt multi-stage filtration system. Regardless of the moisture content in the air, the dew point of the product gas will drop rapidly below -70°C.

☆ Create "one-button control" technology. DAG series dry air generator adopts Siemens PLC intelligent controller, you only need to press the "Start" button to start the equipment, and the equipment runs fully automatically, minimizing manual operation errors.

☆ Air supply time. The dry air can be continuously provided when the equipment is turned on, without time limit.

Specification

|

Item

|

Model

|

DAG-40

|

DAG-60

|

DAG-100

|

DAG-200

|

DAG-300

|

DAG-400

|

DAG-500

|

DAG-600

|

|||||||

|

Air Supply Capacity

|

m3/h

|

40

|

60

|

100

|

200

|

300

|

400

|

500

|

600

|

|||||||

|

Air supply pressure

|

MPa

|

0.05~0.5

|

|

|

|

|

|

|

|

|||||||

|

Working Pressure

|

MPa

|

0.6 ~ 0.8

|

|

|

|

|

|

|

|

|||||||

|

Inlet Air Temp

|

℃

|

≤ 50

|

|

|

|

|

|

|

|

|||||||

|

Continuous working time

|

Hour

|

≥ 200

|

|

|

|

|

|

|

|

|||||||

|

Average Working hours

without troubles |

Hour

|

≥5000

|

|

|

|

|

|

|

|

|||||||

|

Dew Point

|

℃

|

≤ -60 ~ -70℃

|

|

|

|

|

|

|

|

|||||||

|

Particles

|

µm

|

0.01

|

|

|

|

|

|

|

|

|||||||

|

Noise

|

dB (A)

|

60 ~ 80

|

|

|

|

|

|

|

|

|||||||

|

Power Supply

|

|

380 VAC, 60Hz, 3 Phase (or as per actual need)

|

|

|

|

|

|

|

|

|||||||

|

Total Power

|

KW

|

6

|

8

|

16

|

24

|

33

|

47

|

53

|

58

|

|||||||

|

Air Pipe Diameter

|

mm

|

20

|

25

|

32

|

40

|

45

|

50

|

50

|

58

|

|||||||

|

Dimension (L*W*H)

|

mm

|

1350*

1200 *

1600

|

1600*

1420*

1650

|

1900*

1700*

2150

|

2250*

1950*

2400

|

2300*

2000*

2430

|

2350*

2050*

2450

|

2950*

2100*

2750

|

3150*

2200*

2800

|

|||||||

|

Weight

|

KGS

|

450

|

600

|

1350

|

1550

|

2360

|

2850

|

3500

|

3780

|

|||||||

Packing, Delivery, Shipping, Payment Terms

Product after-sales commitment:

1.

One year warranty

for the whole machine

2.The supplier is responsible for free on-site installation, commissioning, training of operators and maintenance essentials.

3.During the specified quality guarantee period, the supplier will be responsible for any defects and failures caused by defects in design process or materials.

4.Provide spare parts at long-term discounts, and provide free technical consultation for a long time. If there is technological innovation, the supplier will upgrade the system of the product purchased by the user free of charge.

2.The supplier is responsible for free on-site installation, commissioning, training of operators and maintenance essentials.

3.During the specified quality guarantee period, the supplier will be responsible for any defects and failures caused by defects in design process or materials.

4.Provide spare parts at long-term discounts, and provide free technical consultation for a long time. If there is technological innovation, the supplier will upgrade the system of the product purchased by the user free of charge.

Hot Searches