- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Longyun

-

Car Model:

-

F 2803

-

Size:

-

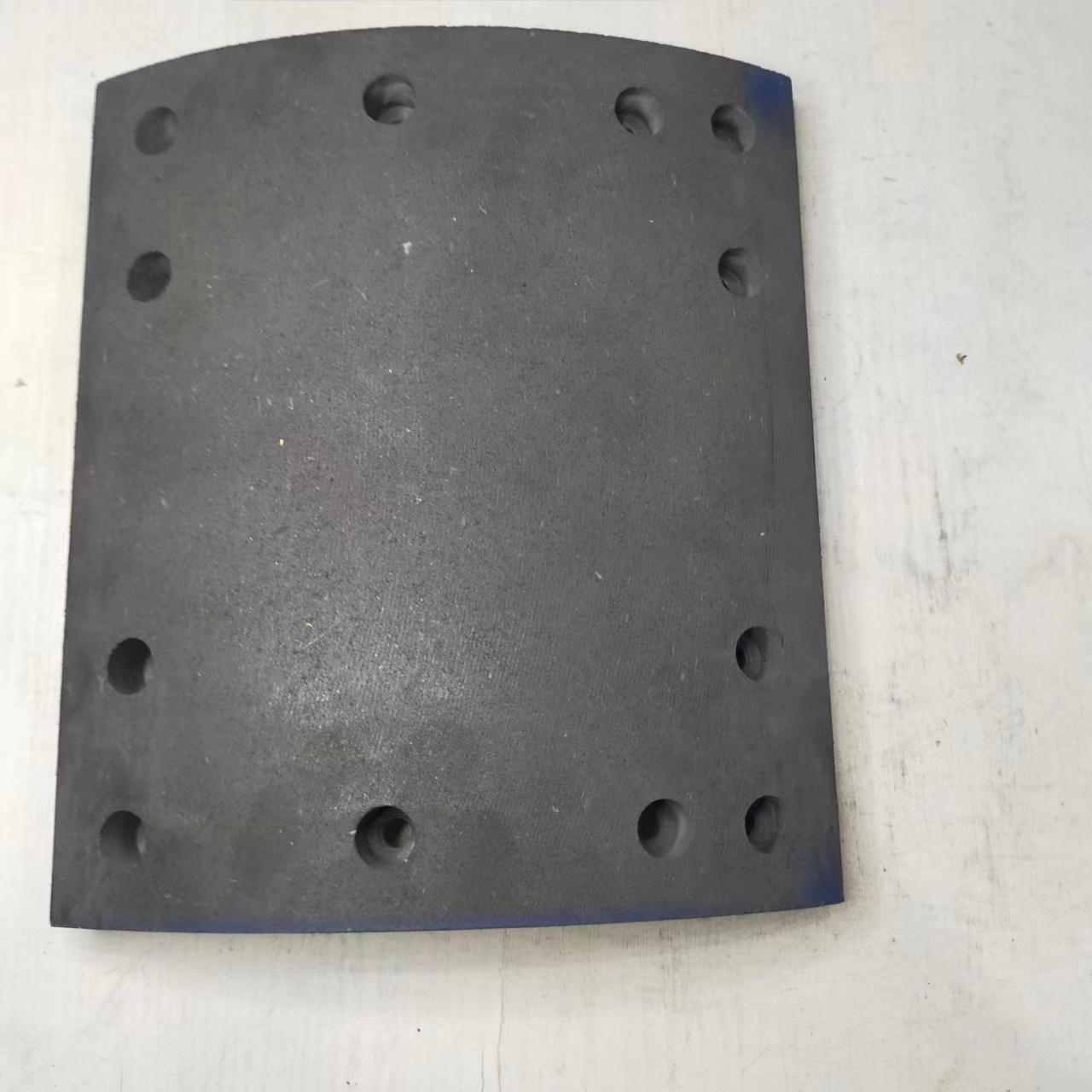

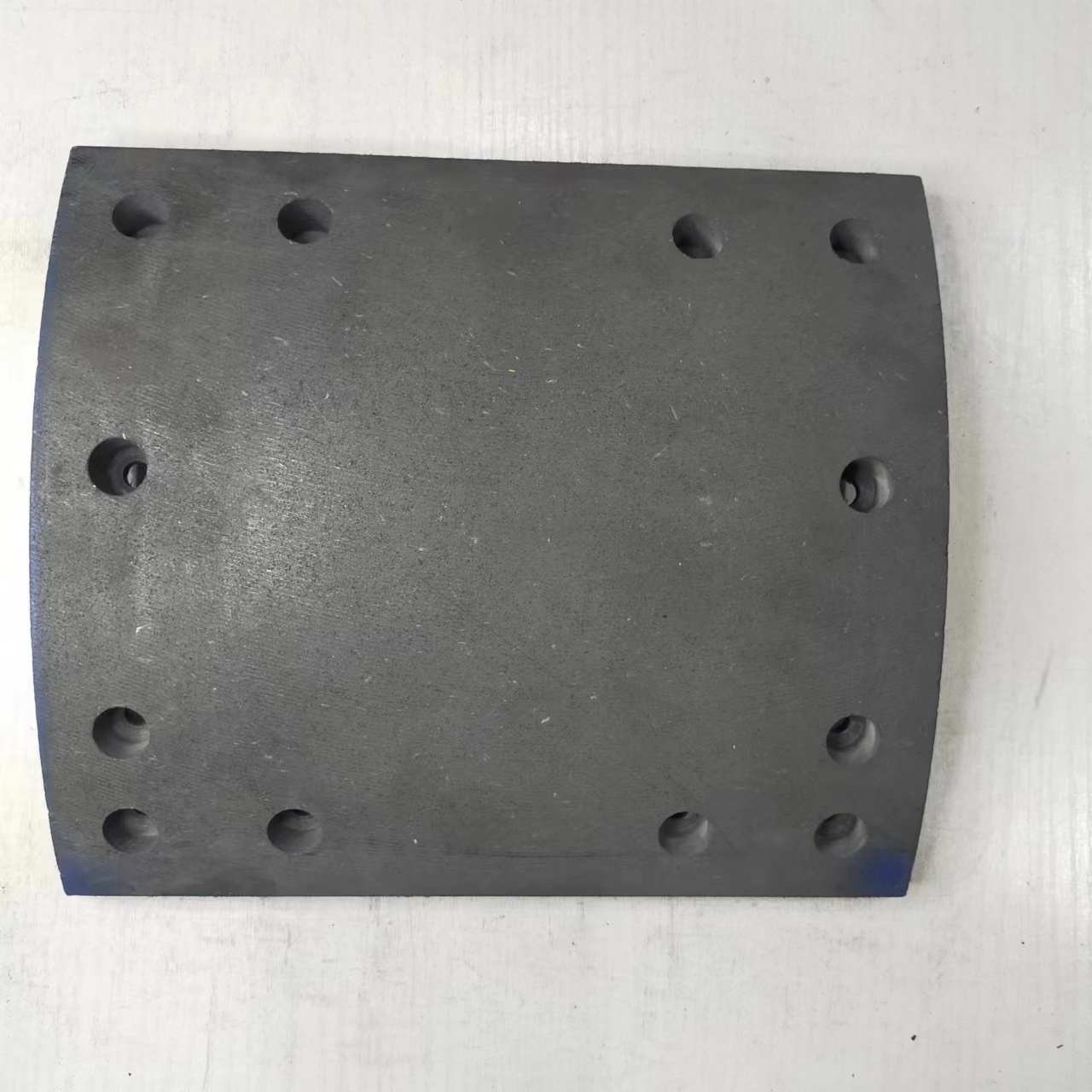

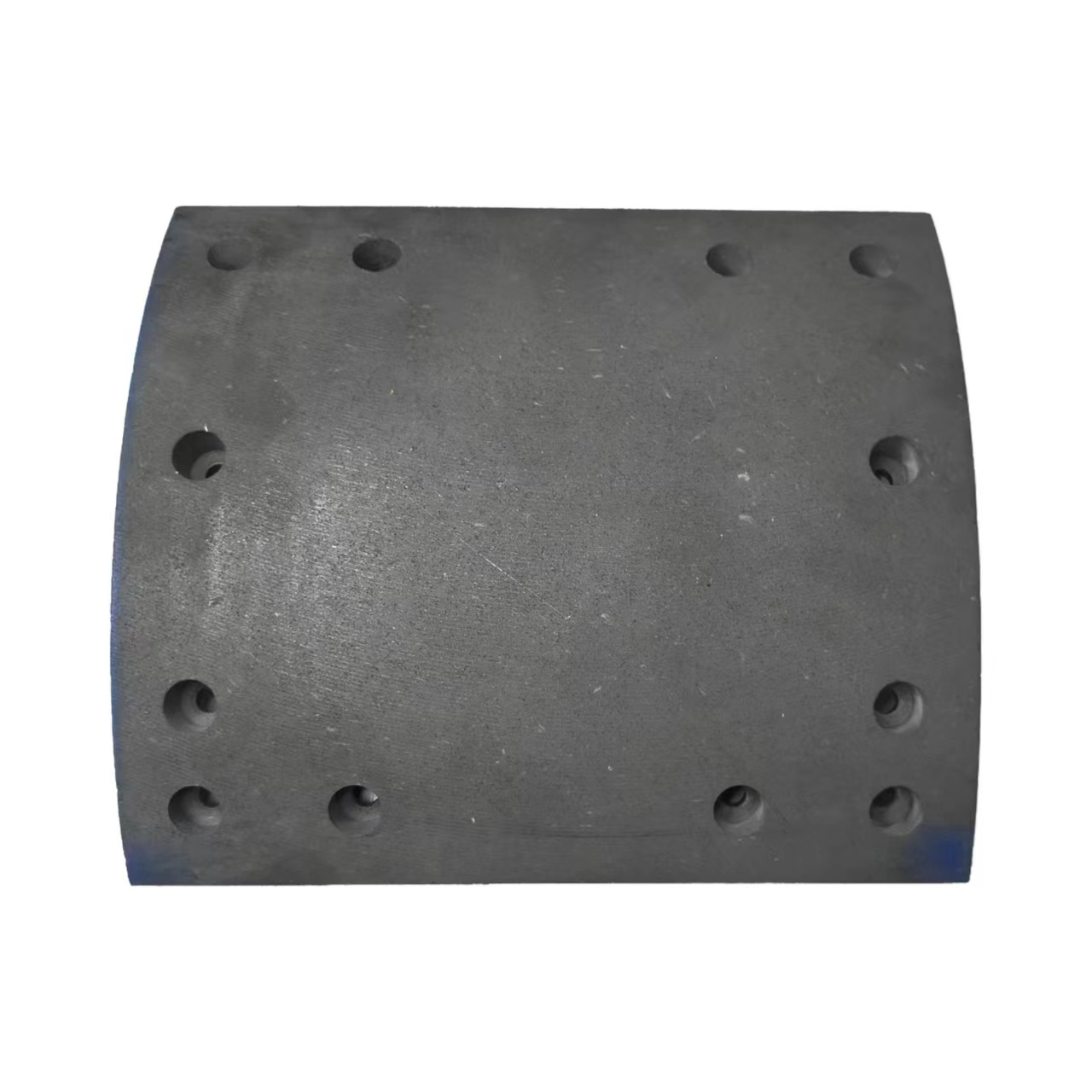

205*219*18.0/11.7 mm

-

Product Name:

-

Brake Pads

-

Brand:

-

Longyun

-

MOQ:

-

50 Sets

-

Certification:

-

ISO9001/TS16949

-

OEM:

-

Available

-

SAMPLE:

-

Available

-

Application:

-

F 2803

-

Quality:

-

100% Tested

-

Guarantee:

-

60000~80000km

Quick Details

-

OE NO.:

-

21200795B

-

Reference NO.:

-

B239518

-

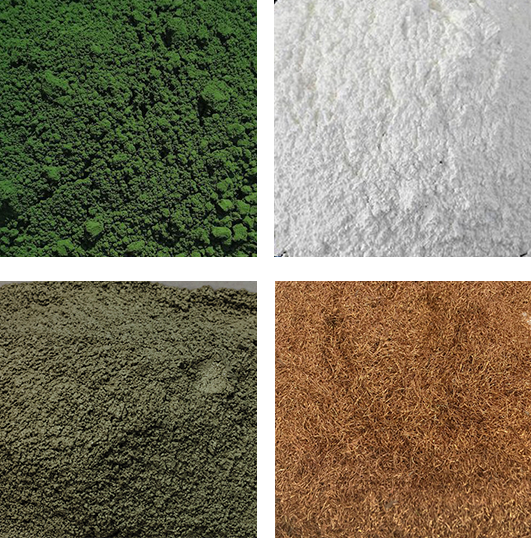

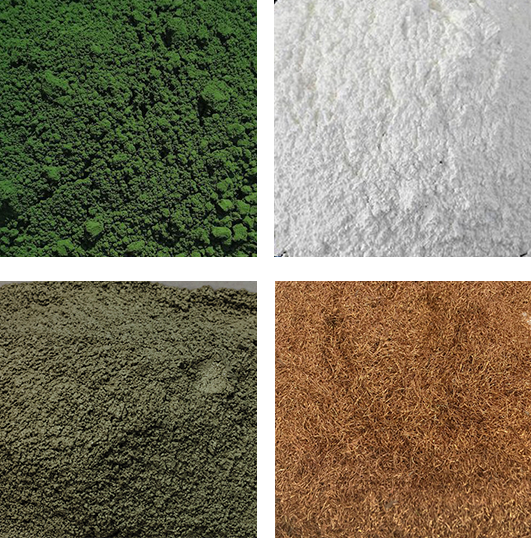

Material:

-

non asbestos, Non asbestos ceramic, Non-asbestos carbon fiber

-

Warranty:

-

1 year

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Longyun

-

Car Model:

-

F 2803

-

Size:

-

205*219*18.0/11.7 mm

-

Product Name:

-

Brake Pads

-

Brand:

-

Longyun

-

MOQ:

-

50 Sets

-

Certification:

-

ISO9001/TS16949

-

OEM:

-

Available

-

SAMPLE:

-

Available

-

Application:

-

F 2803

-

Quality:

-

100% Tested

-

Guarantee:

-

60000~80000km

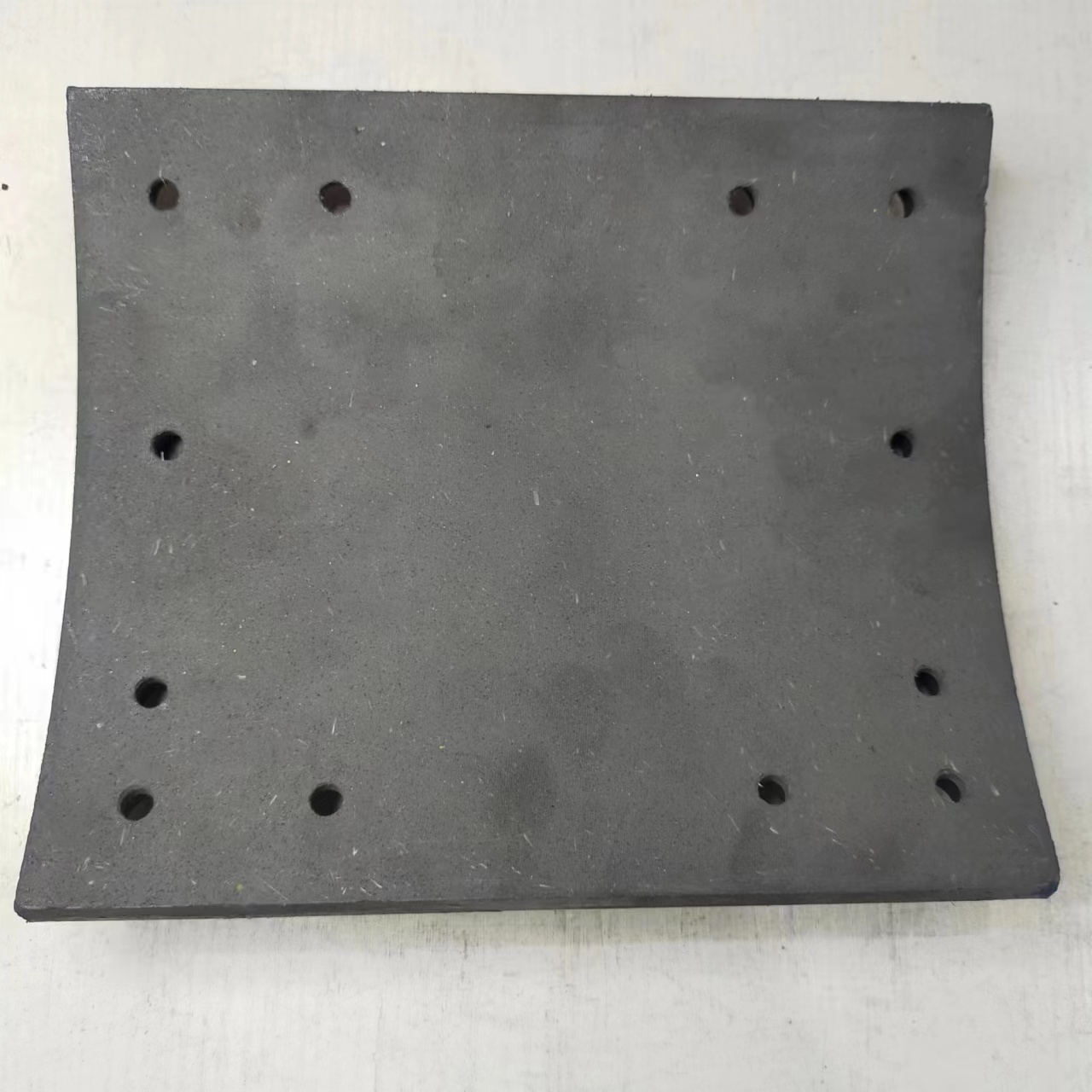

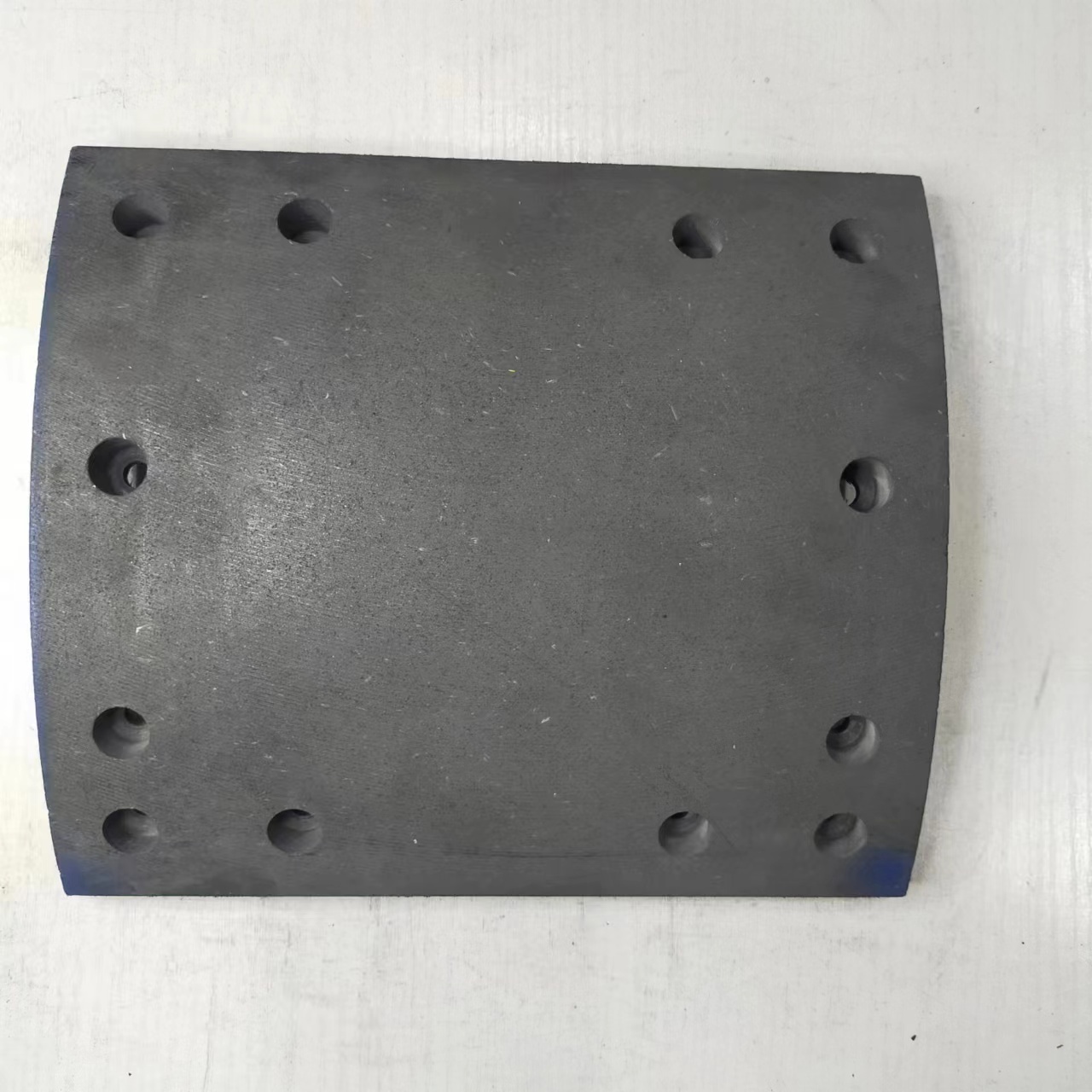

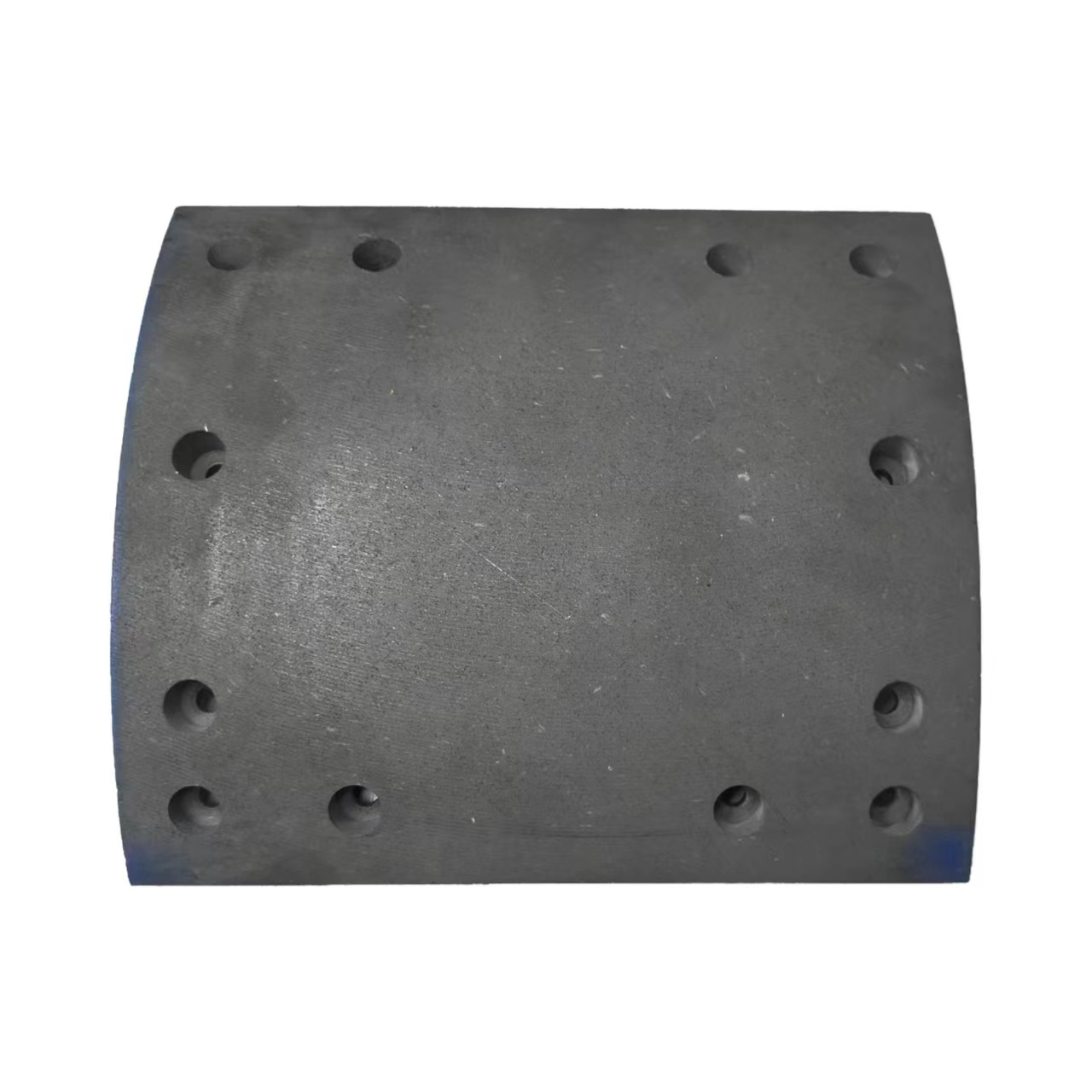

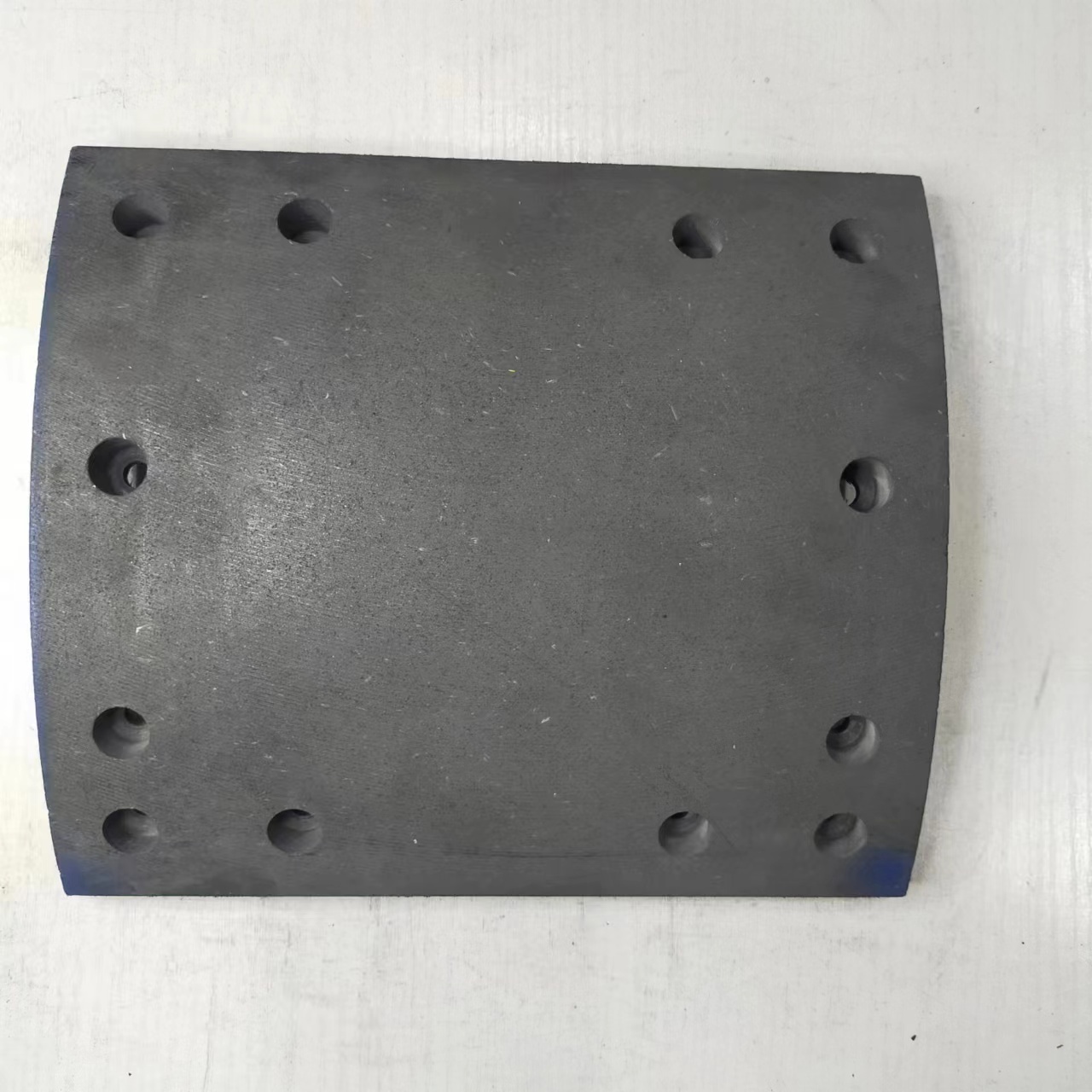

19369 BRAKE LINING

Our factory mainly produces a wide range of the asbestos-free drum brake pads.

In the production process of brake pads, it mainly goes through several stages such as raw material selection and mixing, high-temperature hot pressing, and hot press molding. We strictly control every production process.

19369 Brake pads are formed by hot pressing at high temperatures.

It is mainly suitable for Volvo truck models.

As a high-end brake pad, 19369 brake pads can make the car's braking performance better after installation, and can also be enjoyed in high temperature environments. In addition, it has good friction performance, automatic braking force, large load capacity and strong ability to withstand high loads.

A utomobile brake pads refer to the friction material fixed on the brake drum or brake disc that rotates with the wheel. The friction plates and friction pads are subjected to external pressure to generate friction, thereby achieving the purpose of decelerating the vehicle. Our brake pads are asbestos free brake pads. Asbestos-free brake pads have the characteristics of low noise, safety and environmental protection, stability and reliability.

Our brake pads have three great features: First of all, it has a self-increasing force effect and a large braking force. Secondly, our brake pads are easy to integrate into the handbrake. Last but not least, our brake pads are long lasting and affordable.

.

Traditional brake pad

1.Asbestos material is highly polluting

2.Heavy wear and tear

3.Low coefficient of friction

6.Prone to noise

7.Short service life

2.Heavy wear and tear

3.Low coefficient of friction

4.Braking performance is low

VS

5.More sensitive to temperature

5.More sensitive to temperature

6.Prone to noise

7.Short service life

Non-asbestos brake lining

1.Environmental friendly

2.Strong wear resistance

3.Friction coefficient is stable

4.Strong braking power

5.High temperature resistance

6.No Noise

7.Long Lasting

|

Temperature℃

|

100

|

200

|

300

|

350

|

|

Specified Friction Coefficient

|

0.36

|

0.36

|

0.36

|

0.36

|

|

Allowable Deviation

|

±0.08

|

±0.10

|

±0.12

|

±0.14

|

|

Wear rate

|

≤0.25

|

≤0.45

|

≤0.75

|

≤0.85

|

|

Working Life

|

80,000-120000 Km

|

|

Color

|

black, gray, green, red

|

|

Item Name

|

brake lining

|

|

Model Number

|

19369

|

|

Material

|

non-asbestos

|

|

Packing

|

natural packing

|

|

Brand Name

|

LongYun

|

|

Application

|

truck, trailer, bus

|

|

Applicable Models

|

DAF-Europe F1400

Mercedes Benz 190 Series

Renault ( DONGFENG )

Volvo- Europe 460 Series

|

|

Certification

|

ISO9001/TS16949

|

|

Warranty

|

1 year

|

|

Price

|

12.34 $ /set

|

|

Model

|

ALL

|

|

Place of Origin

|

China

|

|

MOQ

|

50 sets

|

Product Introduction

|

Product Name

|

Brake Lining

|

|

|

|

|||

|

Brand Name

|

Longyun

|

|

|

|

|||

|

Material

|

Non asbestos ceramic, Non-asbestos carbon fiber

|

|

|

|

|||

|

Place of Origin

|

China

|

|

|

|

|||

|

Car Model

|

DAF-Europe F1400

Mercedes Benz 190 Series Renault ( DONGFENG ) Volvo- Europe 460 Series |

|

|

|

|||

|

Size

|

205*219*18.0/11.7 mm

|

|

|

|

|||

|

Warranty

|

Six Month

|

|

|

|

|||

|

Certification

|

ISO9001/TS16949

|

|

|

|

|||

|

MOQ

|

50 Sets

|

|

|

|

|||

|

Packing

|

Neutral box

|

|

|

|

|||

|

Delivery TIME

|

7~10 Days

|

|

|

|

|||

|

Background

|

After decades of development, drum brake pads have been widely used in the automotive field

|

|

Marketing

|

Drum brake pads remain popular on many vehicles due to their reliability and strong stopping power, especially rear wheels. Compared with disc brake pads, drum brakes can have a smaller inner surface of the brake drum, so they are more popular on large load-bearing vehicles that require strong braking power

|

|

Working Principle

|

Drum brakes use the friction between the stationary brake pads in the brake drum and the inner surface of the brake drum that rotates with the wheel speed, thereby, achieving the braking effect.

When you step on the brake pedal, the force of your foot will push the piston in the brake master cylinder, generating pressure, which is then transmitted to the piston of each brake cylinder through the brake fluid, pushing the brake pads to rub against the inner surface of the brake drum to achieve the purpose of braking.

|

|

Precautions

|

To ensure safety, drum brakes require regular inspection and maintenance

|

|

Features

|

Non-asbestos material. Durable, long rotor life. Exceptional stopping power. Low dust level.

Works quietly .

Inner packing: carton, outer packing, standard export carbon.

|

We are your best option

State-of-the-art equipment

We have advanced mixing systems, heat pressing systems, and most importantly, a complete testing system to ensure that all products

have perfect quality.

have perfect quality.

High Quality Raw Materials

We have adopted German technology and developed over a hundred formulas to meet the demands of different types of vehicles.

Quality Control

We have a rigorous quality control system in place,we ensure that all products meet the requirements of our customers.

Features

Low noise

the asbestos-free brake pad material is stable, the friction coefficient is uniform, and it is relatively quiet during braking.

Safety and environmental protection

Asbestos-free brake pads do not contain asbestos, lead and other harmful substances, making them safer and more environmentally

friendly to use.

friendly to use.

Stable and reliable

Asbestos-free brake pads are made of non-asbestos organic composite materials, with stable friction coefficient and long service

life.

life.

Product management

Products : Automotive Disc Brake Pads

Drum brake pads should be replaced every 50,000-80,000 kilometers. Brake pads are wearing parts, so pay special attention to them. However, you can determine the brake pad replacement cycle based on your driving habits. Generally speaking, vehicle brake pads need to be replaced when their thickness is worn to one-third of their original value. Failure to replace the brake pads in time will cause the vehicle to lose control and affect driving safety.

Product specifications

Products : Automotive Disc Brake Pads

Our company is engaged in professional brake pad production. During the production process, certified raw materials, latest technology and 100% quality control are used. As a brake pad manufacturer, we pay close attention to quality and production. Our products are non asbestos ceramic and non asbestos carbon fiber.

Packaging & Delivery

●

We are professional in production of brake lining as well as packing and shipping.

●

We usually use

neutral packing

, also can be

customized according to your requirements

.

Hot Searches