- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

3mm

-

Place of Origin:

-

JIA

-

Weight:

-

1000 kg

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze

-

Production Capacity:

-

2-45m

-

Rolling thinckness:

-

3mm

-

Place of Origin:

-

JIA

-

Weight:

-

1000 kg

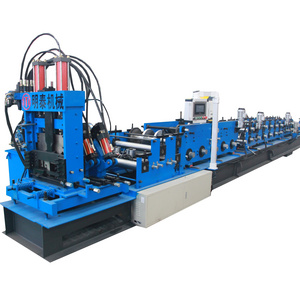

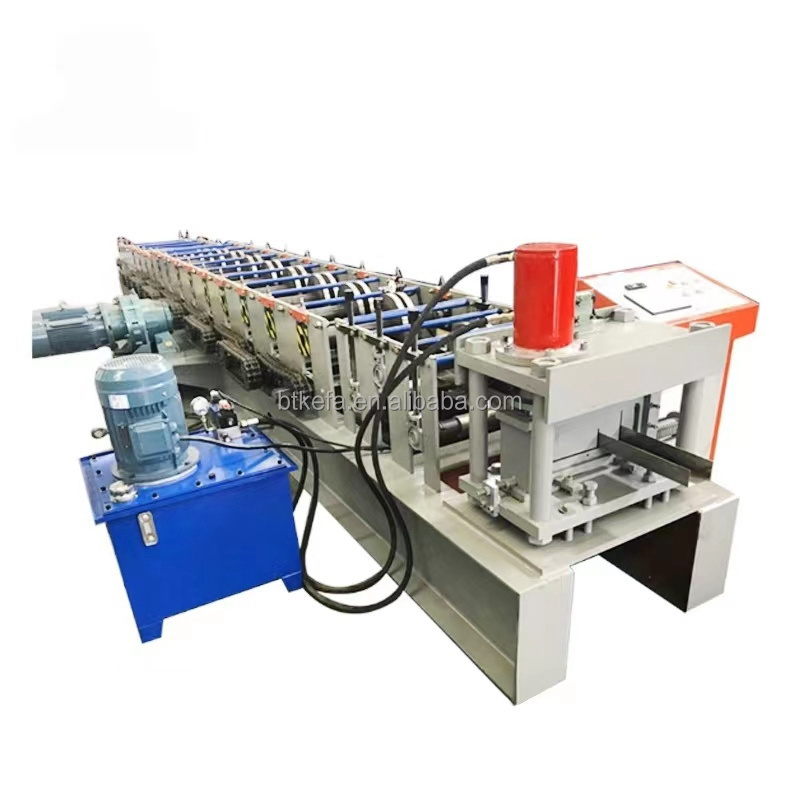

CZ Purlin Roll Forming Machine (Quick Change type CZ80-300)

Main features of interchange cz cold rolled purlins machine

The advantages of CZ purlin machine AUTOMATIC size-change type are as follows:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

The advantages of CZ purlin machine AUTOMATIC size-change type are as follows:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

|

Item

|

Parameters

|

|

Coil Thickness(mm)

|

1.5~3

|

|

Max Speed(m/min)

|

30

|

|

Roll standard station (pcs)

|

18

|

|

Main Motor(KW)

|

22kw (Hydraulic Motor )

|

|

Main Shaft(mm)

|

80mm

|

|

Shaft materials

|

40Cr

|

|

Roller Materials

|

GCr15

|

|

Cutting Way

|

Hydraulic Cutting (7.5KW)

|

|

Cutting Blade Materials

|

Cr12MoV

|

|

Hole Punching

|

3 sets

|

|

Control System

|

PLC control (Xinjie)

|

|

Size Change

|

PLC control / Press Button

|

|

C Z Interchange

|

PLC control / Reverse roll

|

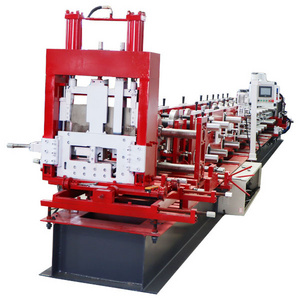

Interchange cz cold rolled purlins machine decoiler

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 5Ton

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 5Ton

Interchange cz cold rolled purlins machine rollers

Rollers manufactured from high quality bearing steel GCr15, CNC lathes, Heat Treatment. with black treatment or Hard-ChromeCoating for options.

With feeding material guide, body framemade from 400# H type steel by welding

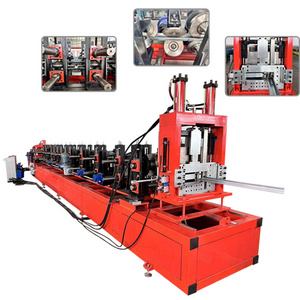

CZ purlin machine punching system

with 3 cylinder(one cyinder for single hole and 2 cylinders for dual-holes.

with 3 cylinder(one cyinder for single hole and 2 cylinders for dual-holes.

Interchange cz cold rolled purlins machine post cutter

No need to change cutter for different size,

made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 30mm steel plate by welding

Pre-punching & Pre-cutting, stop to punch, stop to cut

hydraulic motor:7.5KW, Hydraulic pressure range: 0-16Mpa

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) Please visit company and test machine if convenient.

Hot Searches