- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HECAN

-

Model Number:

-

HC-H4

-

Number of feeder:

-

50

-

Number of head:

-

4

-

Number of camera:

-

6

-

Software version:

-

English(keep updating)

-

Drive motor:

-

Imported Servo Motor

-

Guide rail:

-

TBI Linear Guide rail

-

MAX PCB Area:

-

400*200mm

-

Maximum mounting rate:

-

9500CPH

-

Mounting accuracy range:

-

0201-40*40mm,Pin spacing 0.3mm chip

-

Positioning accuracy:

-

0.01mm

Quick Details

-

Weight (KG):

-

250

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

1.5 Year

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HECAN

-

Model Number:

-

HC-H4

-

Number of feeder:

-

50

-

Number of head:

-

4

-

Number of camera:

-

6

-

Software version:

-

English(keep updating)

-

Drive motor:

-

Imported Servo Motor

-

Guide rail:

-

TBI Linear Guide rail

-

MAX PCB Area:

-

400*200mm

-

Maximum mounting rate:

-

9500CPH

-

Mounting accuracy range:

-

0201-40*40mm,Pin spacing 0.3mm chip

-

Positioning accuracy:

-

0.01mm

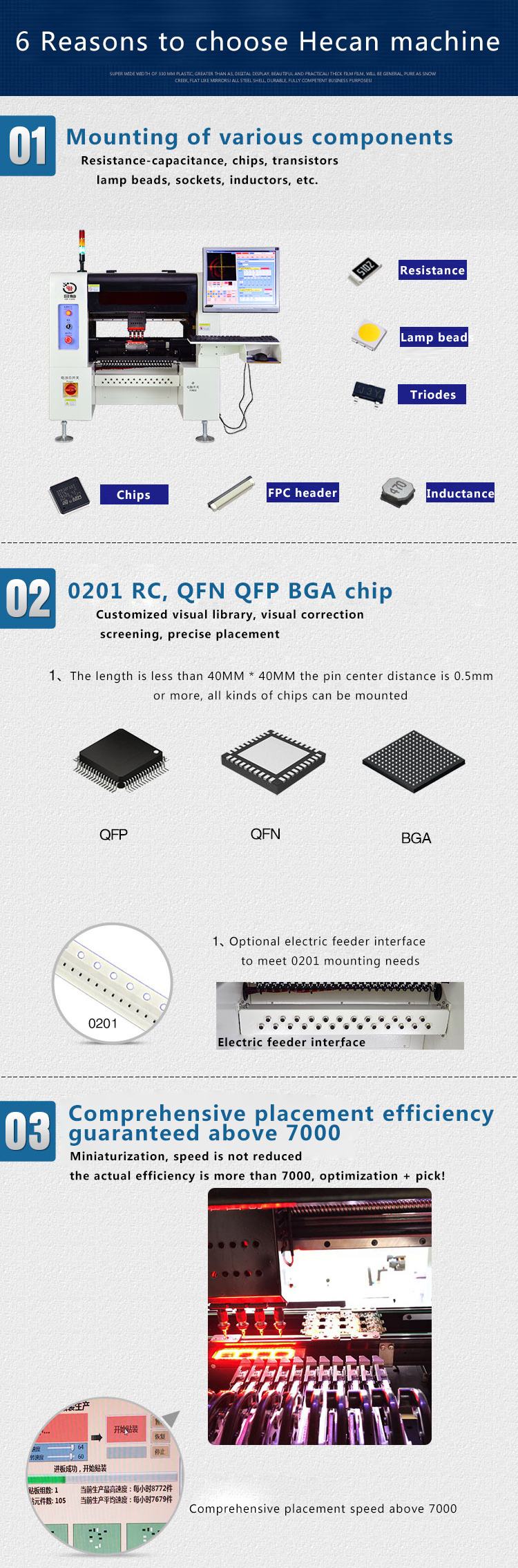

Product Introduction

Introduction

The machine H4 with the ball screw and servo motor which is more stable and accurate than normal step motor, software designed and developed by our self. It is available in English. And we will keep updating it. Customers can get updated software regularly.

Machine is of high quality,with

at least

one-year warranty,

lifetime

maintenance

Feature

1.Based on the desktop H4, this model adds a base, making the assembly line fully automated

2. SMT pick and place machine with 50 feeders +4 heads adopts Panasonic servo motor to ensure it is stable and accuracy

3. SMT pick and place machine uses imported Straight guide rail +screw Guide can get faster speed and more stable

4. Four mounting heads work together, under 6 cameras inspection,come with 50 feeder positions will make machine working more

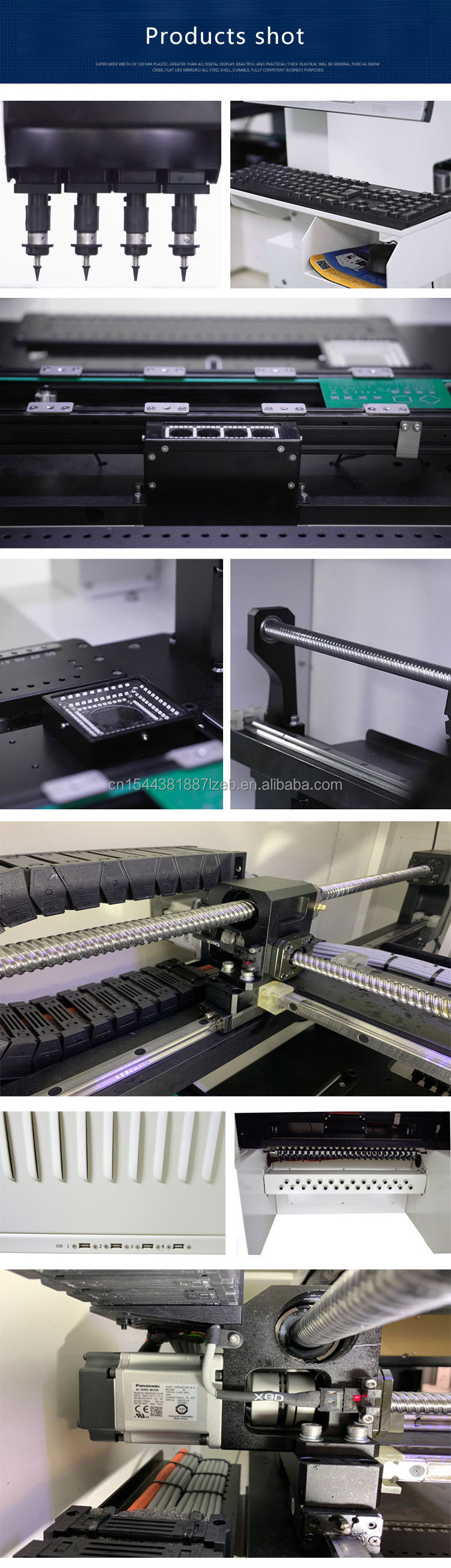

Part List

1.Pick and place machine:1Set

2.IC fixed support:4Sets (four M5*8, four M5*16)

3.JUKI nozzle:12Pcs (502*2,503*3,504*4,505*2,506*1)

4.Calibration suction nozzle:4PCS

5.Power wire:1PC

6.Fixed foot:4PCS (Diameter 20mm)

7.The keyboard and mouse:1Set

8.Nozzle calibration ink-pad:1Box

9.lubricant:1PC

10.Chassis key:1PC

11.PC:1Set

12.17-inch liquid crystal display:1Set

|

Specification

|

|

|

|

Model

|

H4

|

|

|

Number of placement heads

|

4(High accuracy)

|

|

|

Number of calibrated cameras |

6

Mark camera------------------1 Fast recognition camera--4 High-precision camera----1 |

|

|

Number of feeder positions:

|

50/44(can be selected)

|

|

|

Number of trays |

Support up to 48 non- feeder devices, each material can specify its coordinates within the mounting range, and further expand the

single-machine order receiving capability from the practical aspect |

|

|

Maximum mounting speed

|

7000CPH

|

|

|

Avenge mounting speed

|

6000CPH

|

|

|

Combination mounting speed

|

5000CPH

|

|

|

Mounting accuracy range |

0201-40 * 40mm pin pitch 0.3mm chip (In the case of optional support for electric feeder, stable placement of trapezoidal LED lamp

beads in 0603 package, 0402, 0201) |

|

|

PCB entry mode

|

Left-in and right-out automatically enter the board, support the connection function of left and right equipment

|

|

|

Repetition positioning accuracy

|

0.01mm

|

|

|

Nozzle buffer range

|

4.5mm

|

|

|

Maximum moving range of Z axis

|

20mm

|

|

|

Maximum height for components

|

7 mm(can be customized to 20mm)

|

|

|

Maximum PCB circuit board size

|

350×190mm(If it is changed to 44-bit feeder, it can be 350mm×280mm)

|

|

|

Drive motor

|

AC servo motor

|

|

|

Guide rail

|

Linear guide rail

|

|

|

Drive mode

|

Ball screw

|

|

|

Suction nozzle vacuum source

|

High-speed vacuum generator with vacuum release function

|

|

|

Average power

|

600W

|

|

|

Power supply

|

220/110V 50/60Hz

|

|

|

Ensure the normal operation of the equipment. Compressed air pressure range

|

0.5-0.6Mpa

|

|

|

Minimum exhaust volume of air supply source

|

80-120L / min, volume above 50L

|

|

|

Air source quality requirements

|

Oil water filter; ≥50L,dust filter and air pressure stabilizer etc

|

|

|

The trachea requires

|

An outer diameter of 10 mm and a material of PU

|

|

|

Weight (Desk /Vertical)

|

210/280KG

|

|

|

Dimensions (Desk machine)

|

114*90*90CM

|

|

|

Dimensions (Vertical machine )

|

140*90*134CM

|

|

FAQ

Q: How is the training?

A: After buying our machines, we will support all kinds of training (training video +user manual +online training etc.)

Q:Is it hard to use these machines?

A: No, not hard at all. For our previous clients, about 2 days’ training will make them operate the machines easily

Q:Is there any certificate for machine?

A: All of our machines with CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q: The Warranty of the machine?

A:AT least One year, then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

Q:Are machines can meet software update?

A:YES, we will update machine regularly

Q:What kind of maintenance is needed?

A: Add lubricating oil to the guide rail, let the water drain away which from the oil-water separator, and clean the nozzle (we will support this oil)

Service

If you wanna know more, feel free to contact me directly

Mail/Skype:smtmachines@hcpnp.com

Tel/Wechat/WhatsApp:+8618367786556/+8615858886852

Mail/Skype:smtmachines@hcpnp.com

Tel/Wechat/WhatsApp:+8618367786556/+8615858886852

Hot Searches