- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz

-

Power:

-

50kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

15000x6000x3000mm

-

Year:

-

2023

-

Application:

-

Fruit

-

Function:

-

Multifunctional

-

Material:

-

304 Stainless Steel

-

Suitable for:

-

Fruit Processing Industry

-

Capacity:

-

500-1000kg/h

-

MOQ:

-

1 Set

-

Processing Types:

-

Production Line

-

Feature:

-

High Efficiency Easy Operate

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

ANTLER

-

Type:

-

JUICE PRODUCTION

-

Voltage:

-

380V 50Hz

-

Power:

-

50kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

15000x6000x3000mm

-

Year:

-

2023

-

Application:

-

Fruit

-

Function:

-

Multifunctional

-

Material:

-

304 Stainless Steel

-

Suitable for:

-

Fruit Processing Industry

-

Capacity:

-

500-1000kg/h

-

MOQ:

-

1 Set

-

Processing Types:

-

Production Line

-

Feature:

-

High Efficiency Easy Operate

Product Description

Specification

|

Raw material

|

Fresh fruit ( Apple ,pear, mango, pineapple, orange, peach, apricot ......)

|

|

Finished product

|

Juice , puree , concentrate

|

|

Packaging

|

Plastic/glass bottle , Tin cans , Aseptic bricks / bag, pouch etc.

|

|

Processing capacity

|

Input fruit 500kg - 20000kg per hour

|

|

Working voltage

|

380V 50Hz (to be customized)

|

|

Power consumption

|

As per capacity

|

|

Layout

|

As per equipment list

|

The project will be designed base on below information and we shall prepare the quotation accordingly.

1. Raw material : which fruit or vegetable ?

2. End product : juice ? puree or concentrate ?

3. Request processing capacity per hour ?

4. Request packaging for end product ?

Note : Different fruit may requires different juicing system

2. End product : juice ? puree or concentrate ?

3. Request processing capacity per hour ?

4. Request packaging for end product ?

Note : Different fruit may requires different juicing system

Features

* Advanced technology, energy & water saving.

* SUS304/316L material, high qualified component of world famous brand.

* Semi-automatic and fully automatic system for your choice.

* Customized turn-key solution including installation, commissioning at your side.

* The finished product quality is excellent, beautiful color and tasty.

* High productivity, flexible production, can be customized according to customer demand.

* Complete supervision system, equipped with control room to monitor each processing stage.

* Daily output can be clearly record.

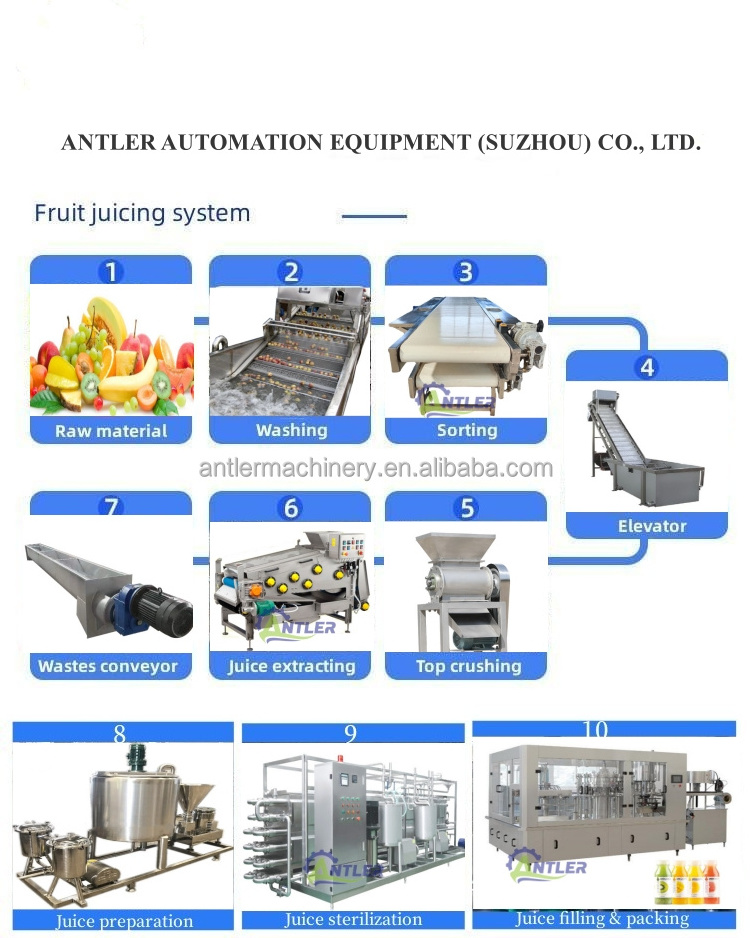

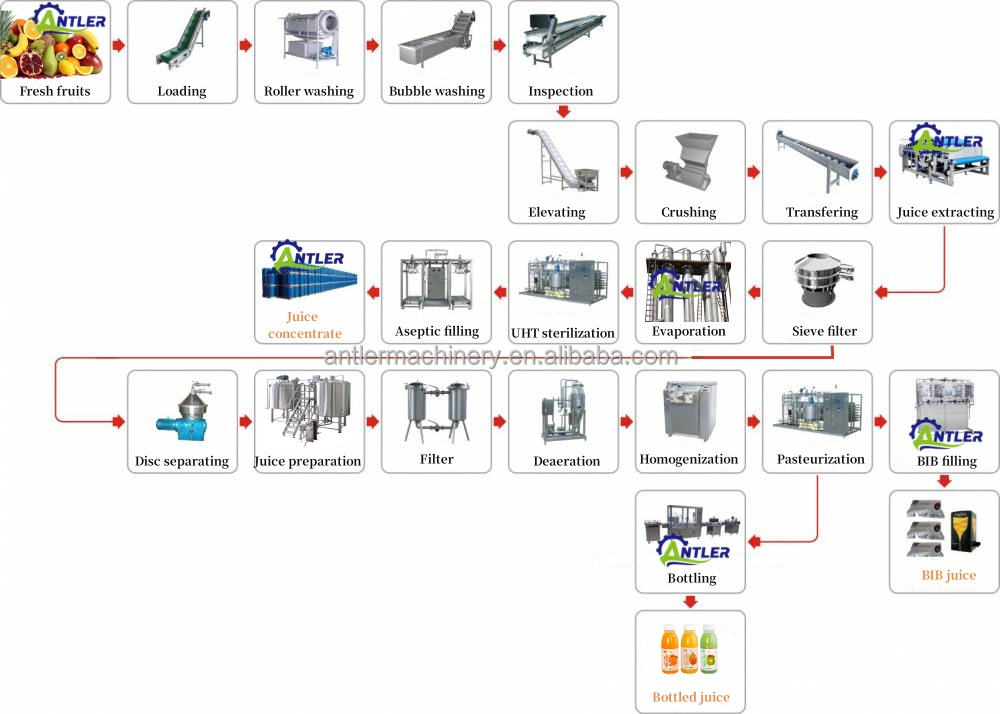

COMPLETE PRODUCTION LINE FOR FRUIT JUICE / PUREE / CONCENTRATE

FROM A TO Z

There are different models of washing machine with variety capacity, we will equip the suitable washing machine base on the raw material and capacity, also along with the loading / feeding elevator and conveyor for transfer the raw material and connect the washing machine to next processing stage.

Water bubble washing machine Brush washing machine Rolling spray washing machine

B.

JUICING AND PULPING SYSTEM

For juice extractor, we would like to recommend you with cold press which with higher juice yield and suitable for most of fruits or vegetables like apples, pears, kiwi, pineapple, carrot, ginger etc. we also have Half cutting juice extractor for citrus fruits like orange,lemon,passion fruit, and pulping extractor for mango, apricot, peach etc.

Cold press juice extractor

Half cutting juice extractor

Double-stage pulping machine

C.

JUICE FILTRATION SYSTEM

The raw juice will be pumped into filtration device

after the juicing system, here below are the filters for your option such as vibrating sieve filter, disc centrifugal, decanter, duplex filter etc. and then the juice is going to the buffer tank and continuously for next processing stage.

Vibrating sieve filter

Disc centrifuge

Decanter centrifuge

D.

JUICE PREPARATION SYSTEM

This system including mixing and blending machine for dosing ingredients and acid balance, and degassing machine for juice deaeration, and next for homogenization which can be effectively prevent the juice precipitation and turbidity. Make sure the juice is well fomulated and for sterilization.

Mixing tank

High pressure homogenizer

Vacuum degassing machine

E. JUICE STERILIZATION SYSTEM

Sterilization machine is the key equipment for juice and concentrate production,there are different model of sterilization machine for your choose.

1. Liquid sterilizer such as HTST sterilizer, UHT plate or tubular sterilizer or pasteurizer

2.End product sterilizer, such as tunnel spray or water bathing pasteurizer, autoclave retort etc.

Tubular pasteurizer

Plate UHT sterilizer

Tube in tube UHT sterilizer

F. FILLING AND PACKING SYSTEM

As per request package for the end product, we can offer you Plastic/glass bottling machine, tin can filling and sealing machine,aseptic bricks filling machine etc. along with auxiliary device like label machine, ink-jet date printer, PE film shrink packing machine and carton box packing machine etc.

Glass/plastic bottling machine

Tin can filling & sealing machine

Aseptic bricks filling machine

Previous Project

Certifications

Hot Searches