Storage Tanks, Heat Recovery units including Heat Recycling from hot steam.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Liquid Flow Rate:

-

customized

-

Maximum Working Pressure:

-

4.5Mpa

-

Weight:

-

7 KG

-

Dimension(L*W*H):

-

customized

-

name:

-

Brazed plate heat exchangers

-

Plate Material:

-

AISI 304, AISI 316L or Titanium

-

Brazing Material:

-

Nickel or Copper

-

Design Temperature:

-

-196~200℃

-

Design Pressure:

-

3.0Mpa

-

Test Pressure:

-

4.5Mpa

-

Channel type:

-

L-M-H

-

Connection type:

-

thread, weled

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Voltage:

-

220V/380V

-

Core Components:

-

heat exchanger

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Liquid Flow Rate:

-

customized

-

Maximum Working Pressure:

-

4.5Mpa

-

Weight:

-

7 KG

-

Dimension(L*W*H):

-

customized

-

name:

-

Brazed plate heat exchangers

-

Plate Material:

-

AISI 304, AISI 316L or Titanium

-

Brazing Material:

-

Nickel or Copper

-

Design Temperature:

-

-196~200℃

-

Design Pressure:

-

3.0Mpa

-

Test Pressure:

-

4.5Mpa

-

Channel type:

-

L-M-H

-

Connection type:

-

thread, weled

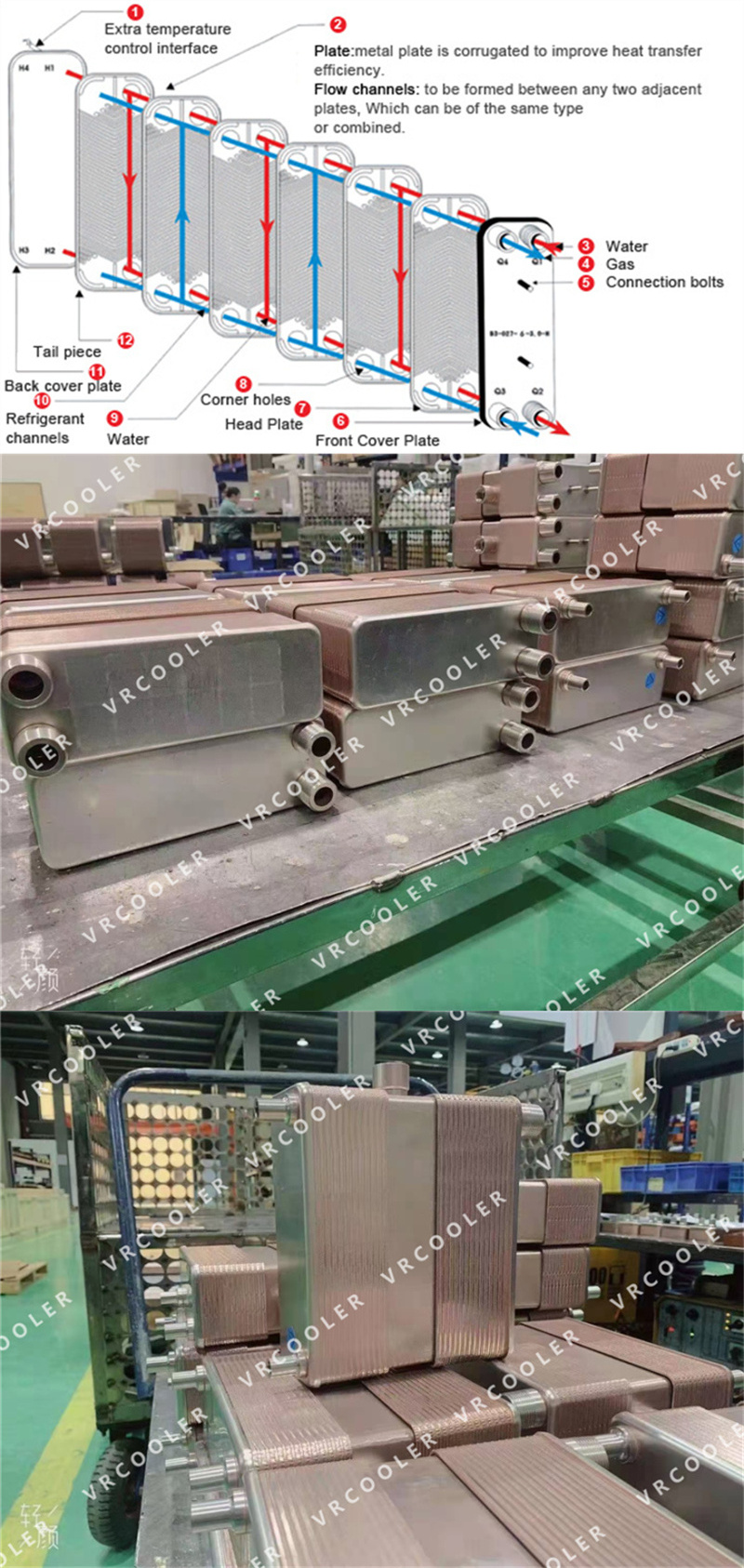

Product Description

Recommended For:

Air-conditioning, Refrigeration, Heat Pump, Process Chillers, Air-dryers, Water Coolers, temperature holding for

Storage Tanks, Heat Recovery units including Heat Recycling from hot steam.

Storage Tanks, Heat Recovery units including Heat Recycling from hot steam.

Key Features:

Highly Efficient Thermal Design – High Performance

More Efficient Use of Materials – Cost Effective

Mass Reduction in Size – Compact, Less Space, Less Weight

Proven and Reliable Quality – Long Lifetime

Durability Flexible in Customizing – Increase Production Efficient

Highly Efficient Thermal Design – High Performance

More Efficient Use of Materials – Cost Effective

Mass Reduction in Size – Compact, Less Space, Less Weight

Proven and Reliable Quality – Long Lifetime

Durability Flexible in Customizing – Increase Production Efficient

Specification

Name: 1. Water to refrigerant brazed plate heat exchanger

2. Good Comments brazed plate heat exchanger

3. Plate heat exchanger for Seafood processing

Pressure:4.0Mpa

Brand:oem

We are professional finned tube heat exchanger manufacturer, do have ranges of material as as following:

|

Tube Materials

|

Fin Materials

|

Frame material

|

Media

|

|

Copper

Aluminum

|

Copper

Aluminum

|

Copper

Aluminum

|

Water

Glycol

|

|

Carbon Steel

Stainless Steel

|

Stainless Steel

|

Carbon Steel

Stainless Steel

|

Air

CO2

|

|

Titanium

Cu-Ni

|

Titanium

|

Titanium

As your required

|

Wind,

etc

|

The following are our hot selling plate heat exchanger replacement models, you can contact us to get our catalogue (customization is possible):

E-mail: keviny@vrcooler.com

Phone: +8615618652003(whatsapp/wechat/skype).

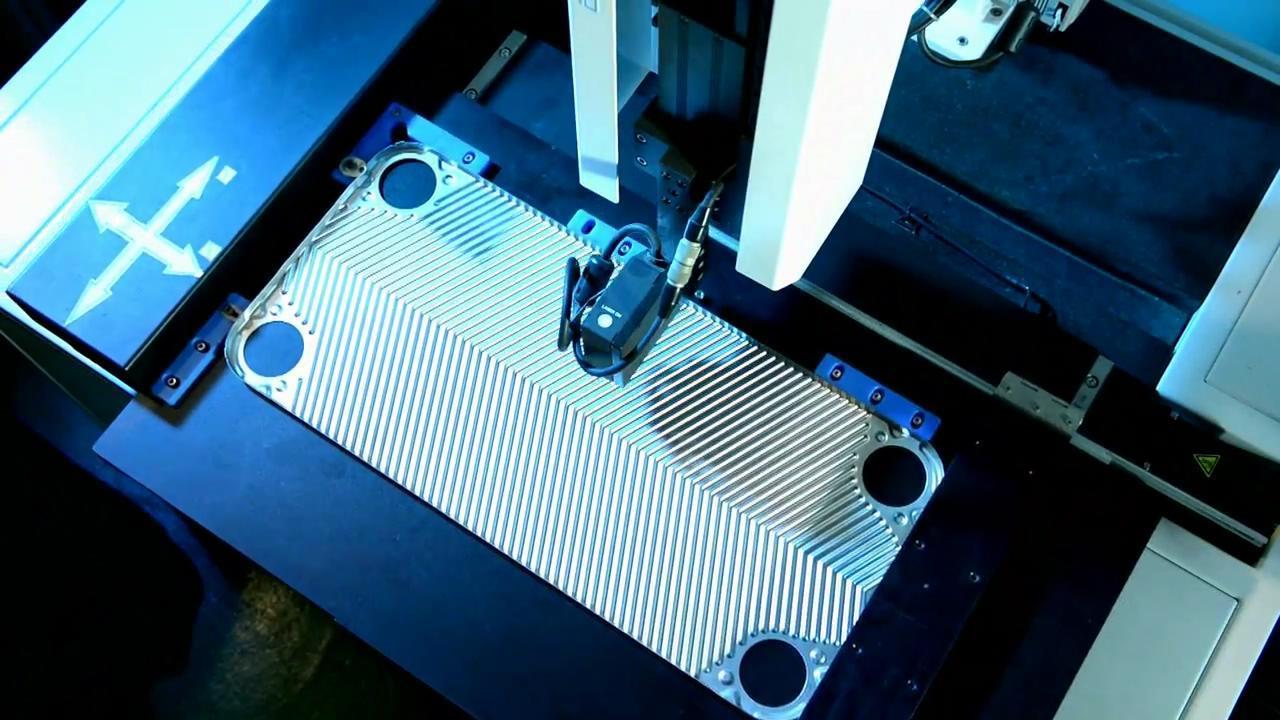

Production process

Our Company

Changzhou Vrcooler Refrigeration Co.,Ltd

provides customers with high-quality and high-effect products based on advanced production technologies ,mature manufacturing processes and strict quality controls and keep communicating with understanding customers demands,which repays us with self improvements and the trust and recognition of customers.

MORE THAN 15 YEARS OF SUCCESS

specializes in researching, manufacturing and exporting Heat Exchangers, Evaporators, Condensers, air cooler and other heat transfer equipments for the varied industries since 2004.

Certifications

FAQ

Q1:

How to contact with us ?

A1: * 24 hours online from Trade Manager, quick answer, or email with us, we chat,what sapp is available.

* Select one product and leave message to us.

Q2: How to purchase the products which you want?

A2: * Choose one product which you are interested and leave message

* Or Inform us your request for brand and model number

* Or inform us your detailed request including dimension, weight, material, we can recommend to you.

* MOQ can be offered for you reference.

Q3: How to confirm the quality before place the order?

A3: * sample can be provided for your testing before order.

* If you are in China, warmly welcome you visit our factory, check the Quality, meanwhile

welcome to visit our office for reference.

Q4: How about the after-sale services ?

A4: * If any problems after receiving the bulk goods, please do not

hesitate to contact us for dealing, our engineer will service at any time to make you satisfied.

A1: * 24 hours online from Trade Manager, quick answer, or email with us, we chat,what sapp is available.

* Select one product and leave message to us.

Q2: How to purchase the products which you want?

A2: * Choose one product which you are interested and leave message

* Or Inform us your request for brand and model number

* Or inform us your detailed request including dimension, weight, material, we can recommend to you.

* MOQ can be offered for you reference.

Q3: How to confirm the quality before place the order?

A3: * sample can be provided for your testing before order.

* If you are in China, warmly welcome you visit our factory, check the Quality, meanwhile

welcome to visit our office for reference.

Q4: How about the after-sale services ?

A4: * If any problems after receiving the bulk goods, please do not

hesitate to contact us for dealing, our engineer will service at any time to make you satisfied.

Related Products

Hot Searches