- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

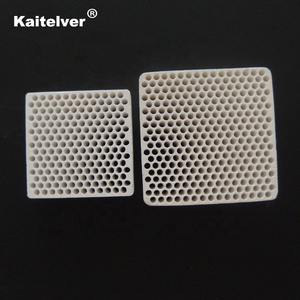

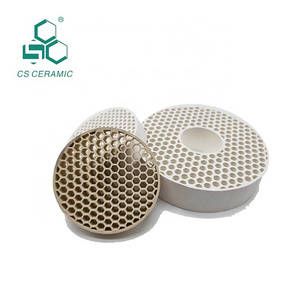

Honeycomb Ceramic Filter Plates For Filtering Molten Metal

-

Application::

-

Refractory, Heat transfer media

-

Model Number::

-

Customized

-

Package:

-

Carton or wooden case with pallets inside or customer's requirements

-

Shape::

-

Customised

-

Usage::

-

Industry Usage

-

Raw material::

-

95%-99% Alumina Ceramic

-

Material::

-

Alumina Ceramic, Cordierite,Mullite,Alundum,etc

-

Size::

-

50*50*12.5mm /55*55mm 81*81/148*148*12.5mmor Customized

-

Certification::

-

ISO9001:2008

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

ZHONGTAI

-

Product name:

-

Honeycomb Ceramic Filter Plates For Filtering Molten Metal

-

Application::

-

Refractory, Heat transfer media

-

Model Number::

-

Customized

-

Package:

-

Carton or wooden case with pallets inside or customer's requirements

-

Shape::

-

Customised

-

Usage::

-

Industry Usage

-

Raw material::

-

95%-99% Alumina Ceramic

-

Material::

-

Alumina Ceramic, Cordierite,Mullite,Alundum,etc

-

Size::

-

50*50*12.5mm /55*55mm 81*81/148*148*12.5mmor Customized

-

Certification::

-

ISO9001:2008

Products Description

Honeycomb ceramic filter plates are widely used for filtering molten metal in metallurgy and casting industries. Mullite

(cordierite) ceramic materials are used, with high-quality and high-density straight hole meshes, so that the products have the characteristics of high heat shock resistance and high sintering temperature resistance. The straight hole design ensures the balance between flow and strength, effectively removes impurities and slag particles, etc., and greatly improves the mechanical properties, surface quality and product qualification rate of castings.

(cordierite) ceramic materials are used, with high-quality and high-density straight hole meshes, so that the products have the characteristics of high heat shock resistance and high sintering temperature resistance. The straight hole design ensures the balance between flow and strength, effectively removes impurities and slag particles, etc., and greatly improves the mechanical properties, surface quality and product qualification rate of castings.

Product Paramenters

|

Item

|

Index

|

Specifications

|

|

Materials

|

Cordierite

|

We can provide you the product by you desire. |

|

Water absorption

|

50.4%

|

|

|

Open Porosity

|

61%

|

|

|

Specific gravity

|

0.6-0.9g/cm3

|

|

|

Thermal expansion coeffecient

|

1.5-3(×10-6K-1)

|

|

|

Temperature softening

|

>1280°C

|

|

|

Cooking Surface Temperature

|

1000-1200°C

|

|

|

CO release

|

≤0.006%

|

|

|

NOx release

|

≤5ppm

|

|

|

Square

|

|

|

Round

|

|

|||

|

40*40*12.5mm

|

81*81*12.5mm

|

148*148*12.5mm

|

40*15mm

|

92*10mm

|

|||

|

50*50*12.5mm

|

98*98*12.5mm

|

66*66*15mm

|

50*15mm

|

50*10mm

|

|||

|

55*55*12.5mm

|

102*102*12.5mm

|

75*32*12.5mm

|

60*15mm

|

90*10mm

|

|||

Product Line

Packing&Delivery

Certification

Our company

Related products

Hot Searches