- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4500*3600*3000mm

-

Year:

-

2024

-

Power (kW):

-

15-160

-

Weight (KG):

-

12500 kg

-

Applicable Industries:

-

rubber factory, rubber sheet processing

-

Name:

-

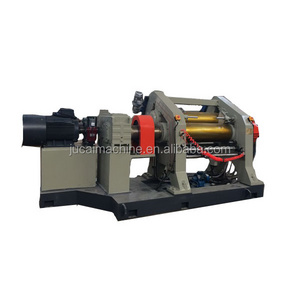

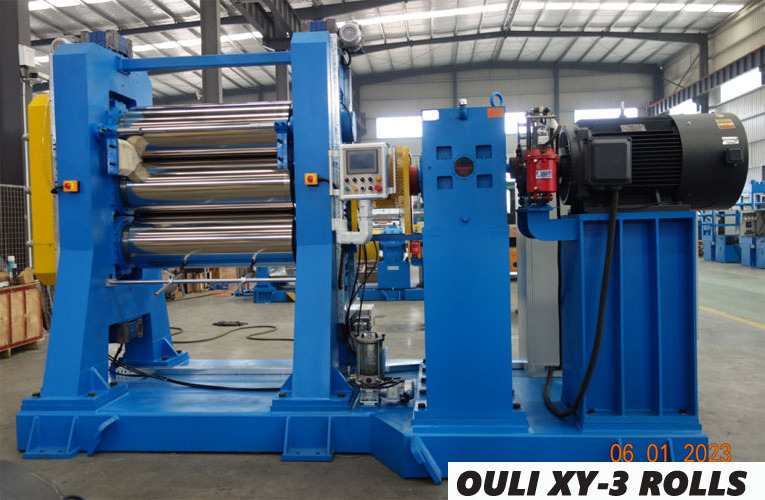

rubber calender machine

-

Application:

-

Rubber calender and Compound

-

Model:

-

2roll/3roll/4roll

-

colour:

-

costomized

-

After-sales Service Provided:

-

Video Technical Support

-

Certification:

-

Customized

-

Function:

-

calender and Compound

-

Control System:

-

Automatic Control

-

Machine Type:

-

Fully Automatically

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OULI

-

Voltage:

-

Customized, Customized

-

Dimension(L*W*H):

-

4500*3600*3000mm

-

Year:

-

2024

-

Power (kW):

-

15-160

-

Weight (KG):

-

12500 kg

-

Applicable Industries:

-

rubber factory, rubber sheet processing

-

Name:

-

rubber calender machine

-

Application:

-

Rubber calender and Compound

-

Model:

-

2roll/3roll/4roll

-

colour:

-

costomized

-

After-sales Service Provided:

-

Video Technical Support

-

Certification:

-

Customized

-

Function:

-

calender and Compound

-

Control System:

-

Automatic Control

-

Machine Type:

-

Fully Automatically

1 Products Description

Rubber calender is the basic equipment in the process of rubber products, it is mainly used to put rubber on fabrics, to rubberize fabrics, or to make rubber sheet.

Features:

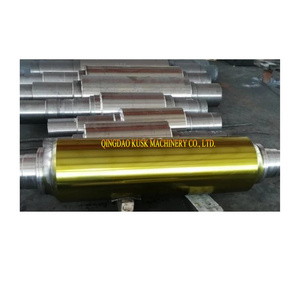

1. Rolls: chilled alloy cast iron rolls with surface hardness 68~72hs. the rolls are mirror finished &

Features:

1. Rolls: chilled alloy cast iron rolls with surface hardness 68~72hs. the rolls are mirror finished &

polished, duly grinding and are hollowed for cooling or heating.

2. Roll clearance adjusting unit: nip adjustment at two roller ends is done manually using two separate

2. Roll clearance adjusting unit: nip adjustment at two roller ends is done manually using two separate

screws attached to the brass housing body.

3. Roll cooling: universal rotary joints with inner spray pipes with hoses and headers. piping is complete

3. Roll cooling: universal rotary joints with inner spray pipes with hoses and headers. piping is complete

up to supply pipe terminal.

4. Journal bearing housing: heavy duty steel casting housing fitted with anti friction roller bearings.

5. Lubrication: full automatic grease lubrication pump for anti friction roller bearings fitted in dust

4. Journal bearing housing: heavy duty steel casting housing fitted with anti friction roller bearings.

5. Lubrication: full automatic grease lubrication pump for anti friction roller bearings fitted in dust

sealed housing.

6. Stand frame & apron: heavy duty steel casting.

7. Gearbox: hard-tooth reduction gearbox, GUOMAO brand.

8. Base frame: common base frame heavy duty, steel channel and ms plate fabricated accurately

7. Gearbox: hard-tooth reduction gearbox, GUOMAO brand.

8. Base frame: common base frame heavy duty, steel channel and ms plate fabricated accurately

machined on which whole machine with gearbox and motor are fitted.

9. Electric panel: star delta electric operating panel with auto reversing, voltmeter, ampere, overload

9. Electric panel: star delta electric operating panel with auto reversing, voltmeter, ampere, overload

protection relay, 3 phase indicator and emergency stop switch.

|

Parameter/model

|

|

XY-2-250

|

XY-2-360

|

XY-2-400

|

XY-2-450

|

XY-2-560

|

XY-2-610

|

XY-2-810

|

|

|

Roll diameter (mm)

|

|

250

|

360

|

400

|

450

|

560

|

610

|

810

|

|

|

Roll working length (mm)

|

|

720

|

1120

|

1200

|

1400

|

1650

|

1730

|

2130

|

|

|

Ratio of rubber speed

|

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

1:1

|

|

|

Roll speed (m/min)

|

|

1.2-12

|

3-20.2

|

4-23

|

2.5-24.8

|

2-18.7

|

4-36

|

2-20

|

|

|

Nip adjust range (mm)

|

|

0-6

|

0-10

|

0-10

|

0-10

|

0-15

|

0.5-25

|

0.2-25

|

|

|

Motor power (kw)

|

|

15

|

37

|

45

|

55

|

75

|

90

|

160

|

|

|

Size (mm)

|

Length

|

3950

|

5400

|

5600

|

7013

|

7200

|

7987

|

8690

|

|

|

|

Width

|

1110

|

1542

|

1400

|

1595

|

1760

|

1860

|

3139

|

|

|

|

Height

|

1590

|

1681

|

2450

|

2460

|

2760

|

2988

|

4270

|

|

|

Weight (KG)

|

|

5000

|

11500

|

12500

|

14000

|

24000

|

30000

|

62000

|

|

|

Parameter/model

|

|

XY-3-250

|

XY-3-360

|

XY-3-400

|

XY-3-450

|

XY-3-560

|

XY-3-610

|

XY-3-810

|

|

|

Roll diameter (mm)

|

|

250

|

360

|

400

|

450

|

560

|

610

|

810

|

|

|

Roll working length (mm)

|

|

720

|

1120

|

1200

|

1400

|

1650

|

1730

|

2130

|

|

|

Ratio of rubber speed

|

|

1:1

|

1:1

|

1:1

|

1:1.5:1

|

1:1.5:1

|

1:1.4:1

|

1:1:1

|

|

|

Roll speed (m/min)

|

|

2-15.9

|

3-20

|

3-26

|

2.6-26.2

|

3-30

|

5.4-54

|

3-30

|

|

|

Nip adjust range (mm)

|

|

0-6

|

0-10

|

0-10

|

0-10

|

0-15

|

0.5-25

|

0.2-25

|

|

|

Motor power (KW)

|

|

22

|

45

|

55

|

75

|

110

|

160

|

132x3

|

|

|

Size (mm)

|

Length

|

3950

|

5400

|

5600

|

7013

|

7200

|

7987

|

8690

|

|

|

|

Width

|

1110

|

1542

|

1400

|

1595

|

1760

|

1860

|

3139

|

|

|

|

Height

|

1810

|

2440

|

2520

|

2900

|

3800

|

3950

|

5050

|

|

|

Weight (KG)

|

|

5500

|

14000

|

18000

|

21000

|

35000

|

42000

|

110000

|

|

|

Parameter/model

|

|

XY-4-230

|

XY-4-360

|

XY-4-400

|

XY-4-450

|

XY-4-550

|

XY-4-610

|

XY-4-810

|

|

|

Roll diameter (mm)

|

|

230

|

360

|

400

|

450

|

550

|

610

|

810

|

|

|

Roll working length (mm)

|

|

630

|

1120

|

1200

|

1400

|

1500

|

1730

|

2500

|

|

|

Ratio of rubber speed

|

|

1:1:1:1

|

0.7:1:1:0.7

|

1:1.4:1.4:1

|

1:1.5:1.5:1

|

1:1.5:1.5:1

|

1:1.4:1.4:1

|

1:1.4:1.4:1

|

|

|

Roll speed (m/min)

|

|

2.1-21

|

2-20.1

|

3-26

|

2.5-25

|

3-30

|

8-50

|

4-40

|

|

|

Nip adjust range (mm)

|

|

0-10

|

0-10

|

0-10

|

0-10

|

0-15

|

0-10

|

0-10

|

|

|

Motor power (KW)

|

|

15

|

55

|

75

|

110

|

160

|

185

|

132x4

|

|

|

Size (mm)

|

Length

|

2800

|

3300

|

6400

|

6620

|

7550

|

7880

|

11400

|

|

|

|

Width

|

930

|

1040

|

1620

|

1970

|

2400

|

2560

|

3900

|

|

|

|

Height

|

1890

|

2350

|

2490

|

2740

|

3400

|

3920

|

5140

|

|

|

Weight (KG)

|

|

5000

|

16000

|

20000

|

23000

|

45000

|

50000

|

130000

|

|

2 Our Advantages

3 Manufacturing Technique

4 Recommend Products

Hot Searches