- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

/

-

Core Components:

-

/

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

WORKING AERA:

-

DUCT PRODUCTION

-

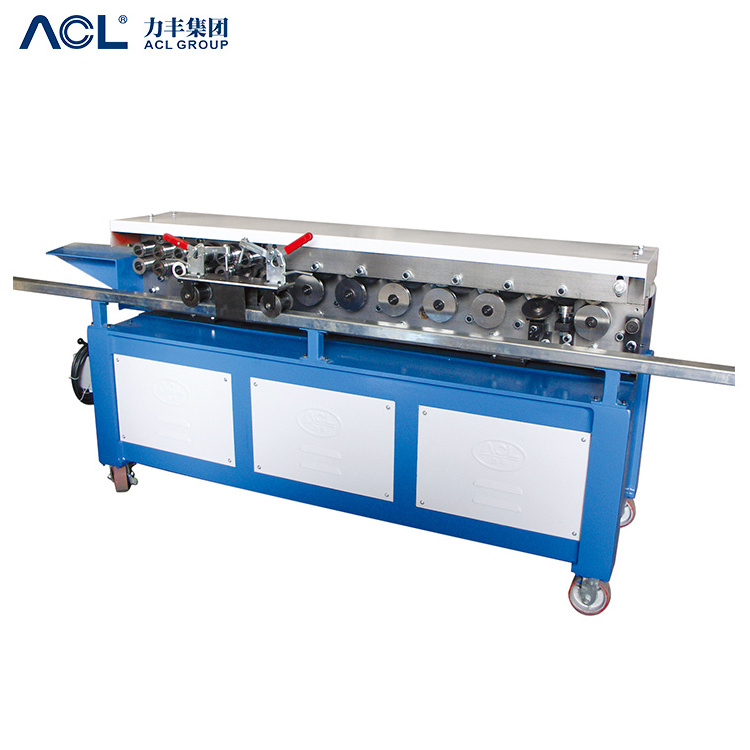

THICKNESS:

-

1.2MM

-

MATERIAL:

-

GALVANIZED STEEL

-

Capaciy:

-

0.5-1.2mm

-

Motor:

-

3kw,4kw

-

"a" size:

-

35-0.5mm

-

Weight:

-

1500kg,3000kg

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ACL

-

Marketing Type:

-

/

-

Warranty of core components:

-

/

-

Core Components:

-

/

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

WORKING AERA:

-

DUCT PRODUCTION

-

THICKNESS:

-

1.2MM

-

MATERIAL:

-

GALVANIZED STEEL

-

Capaciy:

-

0.5-1.2mm

-

Motor:

-

3kw,4kw

-

"a" size:

-

35-0.5mm

-

Weight:

-

1500kg,3000kg

ACL HVAC T-12/2-T-12 High Precision Metal Sheet Duct Forming Machine Flange Machine

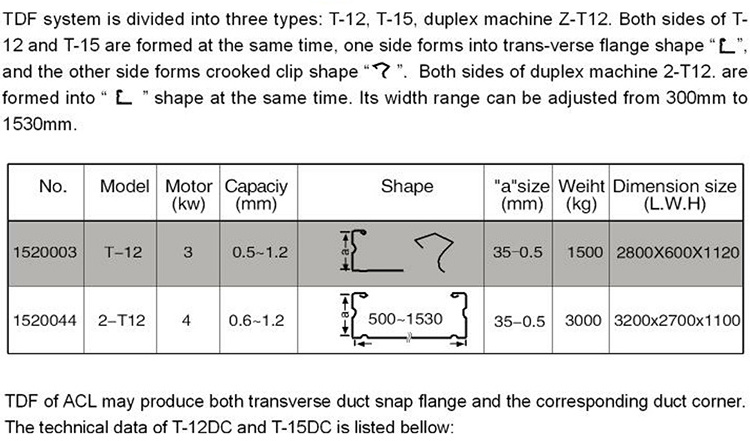

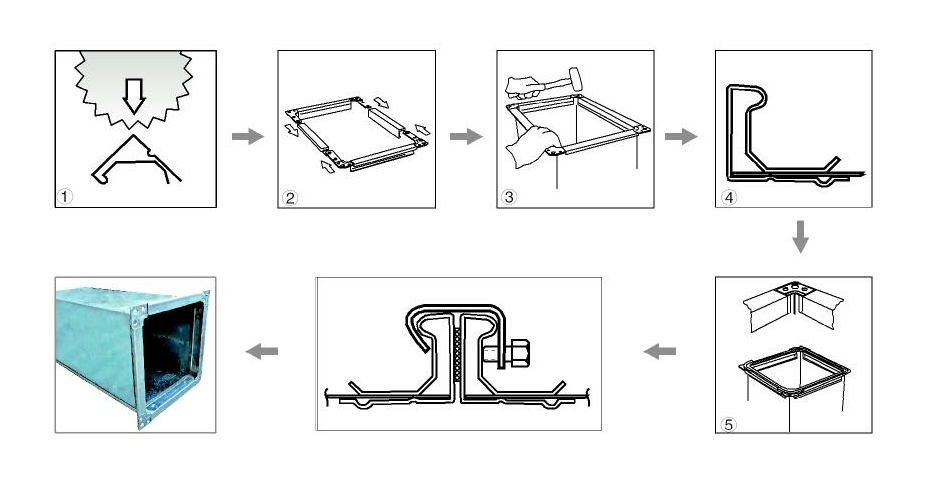

TDF FABRICATION AND INSTALLATION

1.ACL TDC flange only requires ordinary fretsav/ for cutting. The flange strip should be cut to 30mm shorter

than the length of duct groove. The flange also should be cut as the direction shown in the picture to prevent

metal cutting damage on flange structure. The notching should be slippery after cutting.

2.Insert four corner joints into the ends of the flange and ensure the corner joints are fully inserted into the flange. Then the whole flange frame can be fixed.

3.Insert the flange frame into the duct from one side of the frame, then along the v/hole flange frame.

4.Frx the flange into the duct by various methods, spot welding or riveting. But distance for fixing must be taken as standard DW144 Table.

5. The maximum distance from angle to the fixing point should not exceed 50mm.

Our Service

Price : Give me reply, i will give you my favorable price immediately !

Payment term : 4 0% deposit and the balance paid against copy of B/L in 3 days .

Package : Standard exporting package .

Operation manual and video disc :

When delivery machine, the related operation instruction of model will delivery together with machine. And in the instruction, there is teaching video disc .

After-sales service :

1.machine is simple, generally, user can understand how to operate. There is operation instruction and disc .

2.welcome to our factory to learn how to operate our machine, we will give good training .

3.our engineer is available for user. If there is requirement, our engineer can go to user factory, and adjust machine, give good training to user .