- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

(D)2.15m*2.2m

-

Voltage:

-

380V

-

Power:

-

15000-22000

-

Weight (KG):

-

1200

-

Product name:

-

Biochar Charcoal Wood Retort Kiln

-

Color:

-

Green, Silver Or Customized

-

Capacity(kg/h):

-

1000kg/5-8h

-

Host RPM (revolutions per minute):

-

3-5

-

Feeding Way:

-

Automatic frequency conversion feeding

-

Control Cabinet:

-

PLC automatic control cabinet

-

Equipped With:

-

Cooling discharging machine

-

Production Status:

-

With carbonized color display

-

Raw Material:

-

Sawdust, Wood Chip, Coconut Shell, Rice Husk, Cotton Stalk, Straw

-

Usage:

-

Agricultural and forestry biomass charring making

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongyu

-

Effective Volume:

-

Customized

-

Dimension(L*W*H):

-

(D)2.15m*2.2m

-

Voltage:

-

380V

-

Power:

-

15000-22000

-

Weight (KG):

-

1200

-

Product name:

-

Biochar Charcoal Wood Retort Kiln

-

Color:

-

Green, Silver Or Customized

-

Capacity(kg/h):

-

1000kg/5-8h

-

Host RPM (revolutions per minute):

-

3-5

-

Feeding Way:

-

Automatic frequency conversion feeding

-

Control Cabinet:

-

PLC automatic control cabinet

-

Equipped With:

-

Cooling discharging machine

-

Production Status:

-

With carbonized color display

-

Raw Material:

-

Sawdust, Wood Chip, Coconut Shell, Rice Husk, Cotton Stalk, Straw

-

Usage:

-

Agricultural and forestry biomass charring making

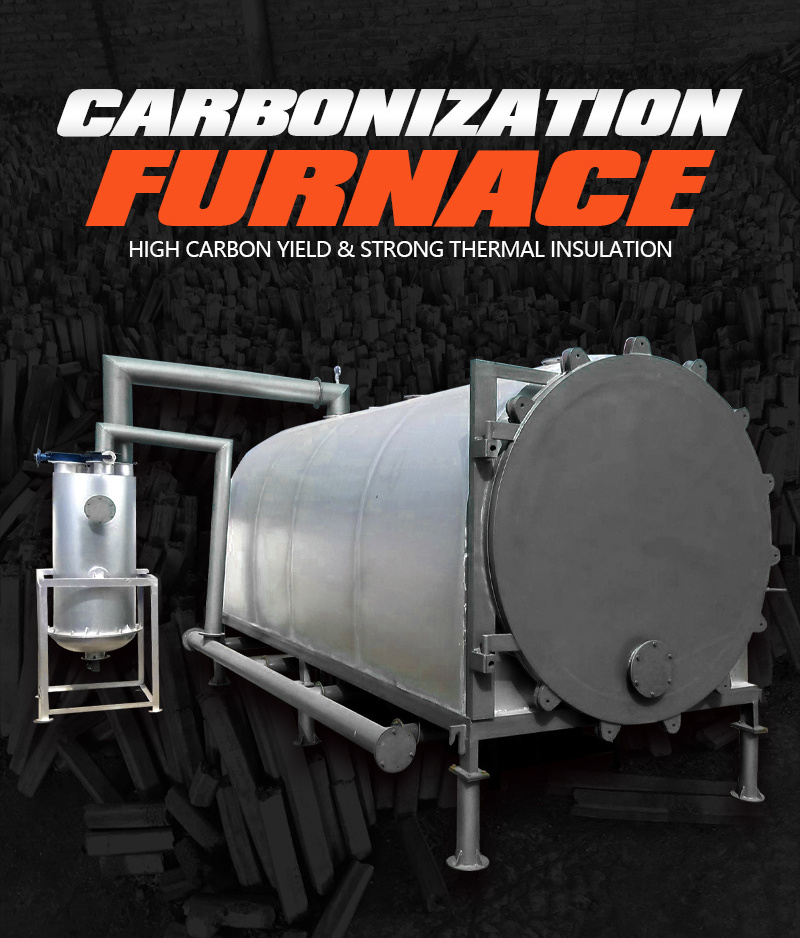

Brand Biomass Charcoal Machine Biochar Charcoal Wood Retort Kiln

Products Description

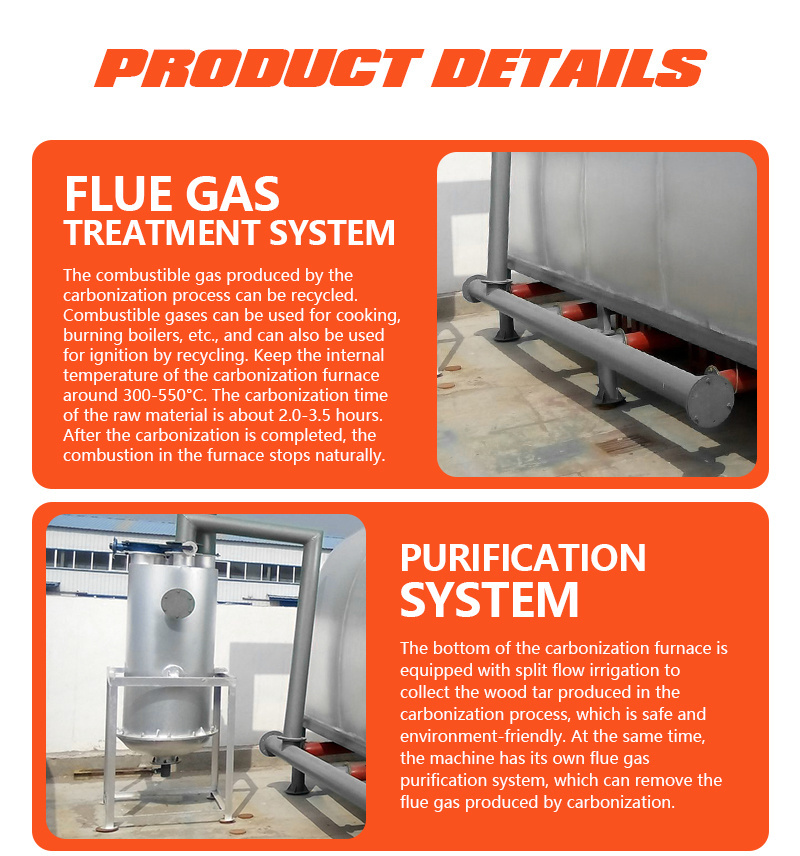

Environmentally-friendly Biochar Charcoal Making Machine uses the carbonized flue gas purification into combustible gas generated in combustion itself. it can continuous product 24 hours. It has an advantages of zero pollution, zero emission, save labor, high capacity, energy-saving consumption, the high degree of automation and advanced technology. Which is suitable for large-scale production, with high carbonation rate, high carbon production rate, energy saving, environmental protection, high efficiency advantages.

Biochar Charcoal Making Machine is suitable for all kinds of forestry and agriculture powder particles. For example, sawdust, wood chip, bamboo, coconut shell, cherry shell, jujube, walnut shell, apricot shell shell shell, peanut shell, rice husk, cotton stalk, straw, the bean curd, etc.

Main Features

1. configuration the early stage of the new type gasifier gasification;

2. configuration of flue gas purification, heat exchange system, cooling system, heat steam into water, flue gas can be converted to gas recycling;

3. configuration frequency conversion feeding machine, automatic feeding, feeding speed is adjustable;

4. configuration rotary carbonation host, meet the production requirements;

5. configuration cooling discharging machine cooling products, output, product;

6. configuration control cabinet, temperature, speed regulation, drum PLC automatic control cabinet, the equipment for carbonized color display, production status should be clear;

Applicable Material

It is suitable for carbonizing coconut shell, cashew husk, walnut shell, apricot shell, hemp pole, sawdust, rice husk, bamboo,eucalyptus, mushroom residue, medicine residue, furfural residue, coffee residue, palm shell, peanut shell, etc.

|

Model

|

Diameter (mm)

|

Length(m)

|

Carbon Production(kg)

|

Power(kw)

|

Size(m)

|

Drum Speed(r/min)

|

|

ZY1010

|

1000

|

10 |

100-200

|

25

|

11*1.5*2.7

|

2-5

|

|

ZY1210

|

1200

|

|

200-300

|

30

|

11*1.8*2.8

|

2-5

|

|

ZY1410

|

1400

|

|

400-500

|

40

|

11*2.0*3.0

|

2-4

|

|

ZY1612

|

1600

|

12 |

600-800

|

50

|

13.5*2.2*3.3

|

2-4

|

|

ZY1912

|

1900

|

|

900-1100

|

60

|

13.5*2.6*3.5

|

2-3

|

|

ZY2212

|

2200

|

|

1200-1500

|

70

|

13.5*3.0*3.7

|

2-3

|

|

ZY2512

|

2500

|

|

1600-2000

|

90

|

13.5*3.1*4.0

|

2-3

|

|

ZY3012

|

3000

|

|

2200-2600

|

120

|

13.5*3.6*4.2

|

2-3

|

|

ZY3612

|

3600

|

|

3000-3800

|

150

|

13.5*4.2*4.5

|

2-3

|

Other Related Technical Parameters

Production in the process of carbonation temperature can reach 500 ℃ to 700 ℃, according to the material characteristics, temperature can be adjusted according to need.

Details Images

Carbonizing Process

First the biomass material is ignited in the gasifier.

The flue gas produced by burning after spraying, cooling, purification process, it produces the pure combustible gas (carbon monoxide, methane, ethane, etc.).

As the early stage of the carbonization of heat source, through early warming of the carbonizer, to feed the material when the heat reaches the special temperature.

The combustible gas that carbonation process of flue gas by spraying, cooling, purification process into burned secondary. According to this methods of circulation, sufficient to achieve a self-sufficient, then achieve the effect of energy saving.

The flue gas through purification, to reach the environment production and flue gas emissions free. Which is reached to the standards of waste gas emptying.

The temperature of carbonization reach a 600 ℃ to 900 ℃ in the process. According to the characteristics of material, the temperature can be adjusted according to the requirements.

Packing&Shipping

Company Introduction

FAQ

Q: What is your Business Model? Trading company or factory?

A:We are a 15 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train.

The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO.

We will pick you up at airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: Zhongyu Group products come with best quality, and our products passed CE certification, exported to lots countries around the word, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of your products?

A: Zhongyu Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, food and lodging, most importantly to guarantee the technician's safety.

Q: What should I provide to get the suitable quotation?

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product?

You can send inquiries from this page.Once we get your answers,we can provide you the best quotation immediately.

Remarks: The price will depend on different models.

Hot Searches