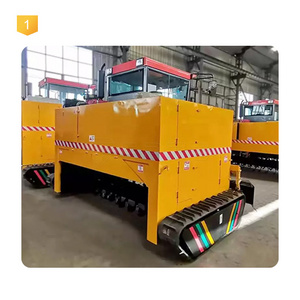

The granulators are critical machine in fertilizer production process.Its quality decides directly the efficiency and quality of end product.Pellets produced via granulator machine are a little more dense,and more sepherical than other agglomeration methods.

It is used for producing high,medium,low concentration of compound fertilizers,organic fertilizer and other kinds of fertilizer,it can also be used for other field,such as agricultural,mining and chemical industry for various products.