We have professional quality control team to ensure our customers' products quality.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

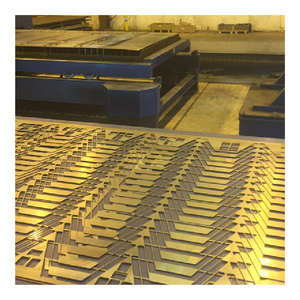

stainless steel fabrication cnc

-

Material:

-

Stainless Steel

-

Process:

-

CNC Laser Cutting/Stamping/CNC Bending/Punching

-

Service:

-

OEM/ODM Service

-

Surface treatment:

-

Sandblasting/Anodized/Zinc Plating/Polish/Laser Engrave

-

Application:

-

Equipment/Medical/Automatic/Electronic/Agricultural machinery

-

Equipment:

-

CNC Machining Centres/CNC Turning Lathe

-

Keyword:

-

cnc fabrication stainless steel

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Tolerance:

-

±0.002mm~±0.005mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

youde

-

Model Number:

-

d23

-

Product name:

-

stainless steel fabrication cnc

-

Material:

-

Stainless Steel

-

Process:

-

CNC Laser Cutting/Stamping/CNC Bending/Punching

-

Service:

-

OEM/ODM Service

-

Surface treatment:

-

Sandblasting/Anodized/Zinc Plating/Polish/Laser Engrave

-

Application:

-

Equipment/Medical/Automatic/Electronic/Agricultural machinery

-

Equipment:

-

CNC Machining Centres/CNC Turning Lathe

-

Keyword:

-

cnc fabrication stainless steel

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Tolerance:

-

±0.002mm~±0.005mm

OUR SERVICES

|

High Quality OEM

CNC

Machining Supplier

|

|

|

|

Service

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Injection Molding,Screw Machining,Springs machining

|

|

|

Materials

|

Aluminum: 2000 series, 6000 series(6061/6063), 7075, 5052, etc.

|

|

|

|

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc.

|

|

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc.

|

|

|

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

|

|

|

Titanium: GradeF1-F5

|

|

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

|

|

|

Surface Treatment

|

Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc.

|

|

|

Tolerance

|

+/-0.002~+/-0.005mm

|

|

|

Surface Roughness

|

Min Ra0.1~3.2

|

|

|

Drawing Accepted

|

Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF, or Samples

|

|

|

Lead Time

|

1-2 weeks for samples, 3-4 weeks for mass production

|

|

|

Quality Assurance

|

ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV

|

|

|

Payment Terms

|

Trade Assurance, TT/ PayPal/ WestUnion

|

|

|

Click Here To Get Quick Quotation!

|

|

|

PRODUCTS DESCRIPTION

QUALITY CONTROL

Quality Control Process

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details beforethe production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC) 5) Checking the goods after they are finished-----Outgoing quality control(OQC)

FACTORY SHOW

COMPANY INTORDUCTION

Welcome to know more about Youde.

1.2500 square meters factory mainly provides CNC machining service.

2.ISO certificated,supports third-party verification.

3.Deliver conventional products in 15 days at the soonest.

4.Engineering service provided.

FAQ

1.Are you a manufacturer or a trading company?

We are a 2500-square-meter factory located in Huizhou, China. Manager office set on Longgang ,Shenzhen.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Back to homepage>>>

Hot Searches