- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

1A1

-

Product name:

-

Knife Sharpening Polishing Wheel

-

Application:

-

Polishing Surface

-

Material:

-

100% Wool

-

Shape:

-

Round Disc

-

Color:

-

Natural White

-

Density:

-

65

-

MOQ:

-

2pcs

-

Size:

-

250*30*12mm

-

Delivery time:

-

7-15days

Quick Details

-

Type:

-

Polishing wheel

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Model Number:

-

1A1

-

Product name:

-

Knife Sharpening Polishing Wheel

-

Application:

-

Polishing Surface

-

Material:

-

100% Wool

-

Shape:

-

Round Disc

-

Color:

-

Natural White

-

Density:

-

65

-

MOQ:

-

2pcs

-

Size:

-

250*30*12mm

-

Delivery time:

-

7-15days

Products Description

diamond CBN grinding sharpening wheels

1A1 Knife Sharpening Tormek Diamond Sharpening Wheel is made of Steel / Aluminum and Diamond Brasives. We use advanced electroplating process to coat diamond abasives on Steel or Aluminum hubs. Selected diamond abrasives and Solid steel rods and aluminum rods are applied in our products. It makes our products performing well on the quality and appearance.We have much experience in woodworking industry machining.Mainly used for the grinding of circular saw blade, disc saw,chainsaw,bandsaw , etc.

Welcome to wholesale & OEM & ODM.

Welcome to wholesale & OEM & ODM.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Features.

1.There are various types, such as electroplated/resin diamond whetstone, cbn whetstone.

2.Selected Diamond and CBN abrasives

3.Diamond distribution is very well

4.Double sided with Rough / Fine grits

5.Kinds of Grits group: #350/600, #180/220, #150/1000, #350/1000

6.Easy to take

2.Selected Diamond and CBN abrasives

3.Diamond distribution is very well

4.Double sided with Rough / Fine grits

5.Kinds of Grits group: #350/600, #180/220, #150/1000, #350/1000

6.Easy to take

Applications

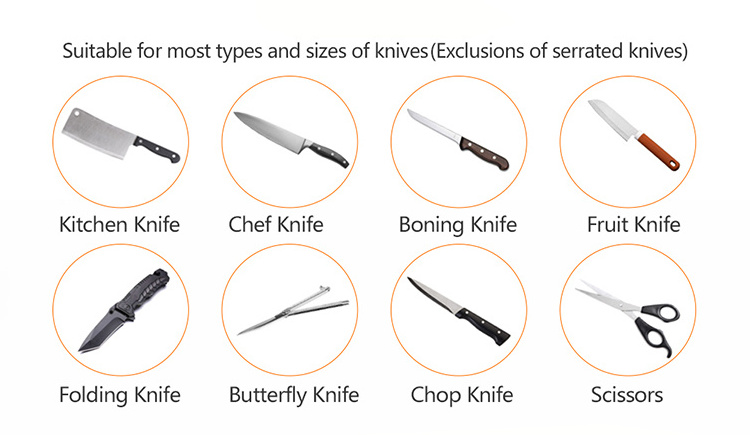

8 inch double sided whetstone knife sharpener stone Metal Knives eletroplated diamond sharpening stones,suitable for most types and knives, for example kitchen knife, chef knife, boning knife, fruit knife, folding knife, chop knife, scissors.Welcome to wholesale & OEM & ODM.

Applicable machine brand:

TORMEK T8/T7

Selection of grinding wheel elements.

1.hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit

grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of

the grinding wheel.

grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of

the grinding wheel.

Relative products

Customer Reviews

Hot Searches