5-point twin toggle clamping system by modular optimization software designing.Strong clamping with rapid and stable, tomeet the strict clamping condition.

Mould height adjustment by hydraulic driven gear system with rapid and stable. Automatic mould height adjustment as per the setting clamping force(optional).

- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

8000 kN

-

Theoretical Shot Volume(cm³):

-

4802 cm³

-

Injection Rate (g/s):

-

867 g/s

-

Injection Weight (g):

-

30 g

-

Screw Speed (rpm):

-

0 - 100 rpm

-

Screw diameter (mm):

-

505 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

1150X1110

-

Weight (KG):

-

56000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

1100 mm

-

Model Number:

-

AF1080

-

Brand Name:

-

Ipack

-

Power (kW):

-

100 kW

-

Clamping Force:

-

950~8000kn

-

Controlled:

-

PLC (Siemens)

-

Motor:

-

Energy Saving Pump

-

Application:

-

Pet Preform / Cap etc...

-

Total Power:

-

50kw

-

Voltage:

-

Customized

-

Shot Weight:

-

320g-2500g

-

Injection Pressure:

-

80MPa-200MPa

-

Injection Rate:

-

160g/S-560g/S

-

Certificated:

-

CE, ISO

Quick Details

-

Plasticizing Capacity(g/s):

-

160-560

-

Mold Height(mm):

-

500 - 1100 mm

-

Ejector Stroke(mm):

-

320 mm

-

Ejector Force(kN):

-

8000 kN

-

Theoretical Shot Volume(cm³):

-

4802 cm³

-

Injection Rate (g/s):

-

867 g/s

-

Injection Weight (g):

-

30 g

-

Screw Speed (rpm):

-

0 - 100 rpm

-

Screw diameter (mm):

-

505 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

1150X1110

-

Weight (KG):

-

56000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

1100 mm

-

Model Number:

-

AF1080

-

Brand Name:

-

Ipack

-

Power (kW):

-

100 kW

-

Clamping Force:

-

950~8000kn

-

Controlled:

-

PLC (Siemens)

-

Motor:

-

Energy Saving Pump

-

Application:

-

Pet Preform / Cap etc...

-

Total Power:

-

50kw

-

Voltage:

-

Customized

-

Shot Weight:

-

320g-2500g

-

Injection Pressure:

-

80MPa-200MPa

-

Injection Rate:

-

160g/S-560g/S

-

Certificated:

-

CE, ISO

Product Overview

Hydraulic Injection Molding Machine For Plastic Products

We supplied clamping force ranges from 98ton to 3400ton injection molding machine. besides, we also have special machine for PVC, PET, Variable Pump, clear double color, servo-motor machine,high speed injection machine.

PRODUCT SPECIFICATIONS

|

Model

|

Clamping Force

|

Shot weight A/B

|

|

Heat power

|

Pump power

|

Oil tank capacity

|

Dimensional

|

Weight

|

|

|

BST-1000A

|

1000KN

|

128g

|

162g

|

7.6KW

|

11KW

|

180L

|

4.3*1.5*1.6M

|

3.4T

|

|

|

BST-1320A

|

1320KN

|

188g

|

205g

|

8.2KW

|

13KW

|

200L

|

4.5*1.6*1.7M

|

3.9T

|

|

|

BST-1400A

|

1400KN

|

230g

|

252g

|

8.2KW

|

13KW

|

220L

|

4.8*1.6*1.7M

|

4.2T

|

|

|

BST-1650A

|

1650KN

|

286g

|

326g

|

8.2KW

|

15KW

|

250L

|

5.0*1.6*1.7M

|

5T

|

|

|

BST-1800A

|

1800KN

|

335g

|

378g

|

11KW

|

15KW

|

250L

|

5.3*1.6*1.8M

|

5.5T

|

|

|

BST-2050A

|

2050KN

|

415g

|

472g

|

11.6KW

|

17KW

|

270L

|

5.4*1.6*1.8M

|

6T

|

|

|

BST-2300A

|

2300KN

|

546g

|

592g

|

11.6KW

|

18.5KW

|

300L

|

5.7*1.8*2.0M

|

6.5T

|

|

|

BST-2600A

|

2600KN

|

650g

|

690g

|

15.5KW

|

25KW

|

350L

|

6.1*1.7*1.8M

|

8T

|

|

|

BST-3000A

|

3000KN

|

709g

|

760g

|

15.5KW

|

25KW

|

370L

|

6.5*1.8*1.8M

|

9T

|

|

|

BST-3400A

|

3400KN

|

772g

|

826g

|

17.5KW

|

30KW

|

400L

|

6.7*2.0*1.9M

|

10.8T

|

|

|

BST-3850A

|

3850KN

|

1008g

|

1072g

|

17.5KW

|

30KW

|

400L

|

7.0*2.2*2.0M

|

11.8T

|

|

|

BST-4500A

|

4500KN

|

1430g

|

1512g

|

20.5KW

|

37KW

|

450L

|

7.3*2.3*2.4M

|

13.8T

|

|

|

BST-4800A

|

4800KN

|

1590g

|

1670g

|

23.4KW

|

40KW

|

600L

|

8.3*2.2*2.2M

|

16.2T

|

|

|

BST-5200A

|

5200KN

|

1980g

|

2130g

|

28.1KW

|

43.5KW

|

750L

|

8.6*2.2*2.3M

|

20T

|

|

|

BST-5800A

|

5800KN

|

2230g

|

2430g

|

28.1KW

|

48.5KW

|

850L

|

8.75*2.2*2.3M

|

21.8T

|

|

|

BST-6500A

|

6500KN

|

2745g

|

2870g

|

37.1KW

|

55KW

|

1000L

|

9.2*2.2*2.4M

|

26T

|

|

|

BST-7500A

|

7500KN

|

3810g

|

3960g

|

40.9KW

|

67KW

|

1200L

|

10.7*2.3*2.7M

|

38T

|

|

|

BST-8500A

|

8500KN

|

4200g

|

4350g

|

42.5KW

|

74KW

|

1300L

|

11*2.4*2.8M

|

45T

|

|

High Efficiency Energy Saving Injection Molding Machine adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family.The LCD displaying screen with high clarity has Chinese and English language to use.Close-loop PID temperature control with the advantage of high precision.The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators's safety.

Details Images

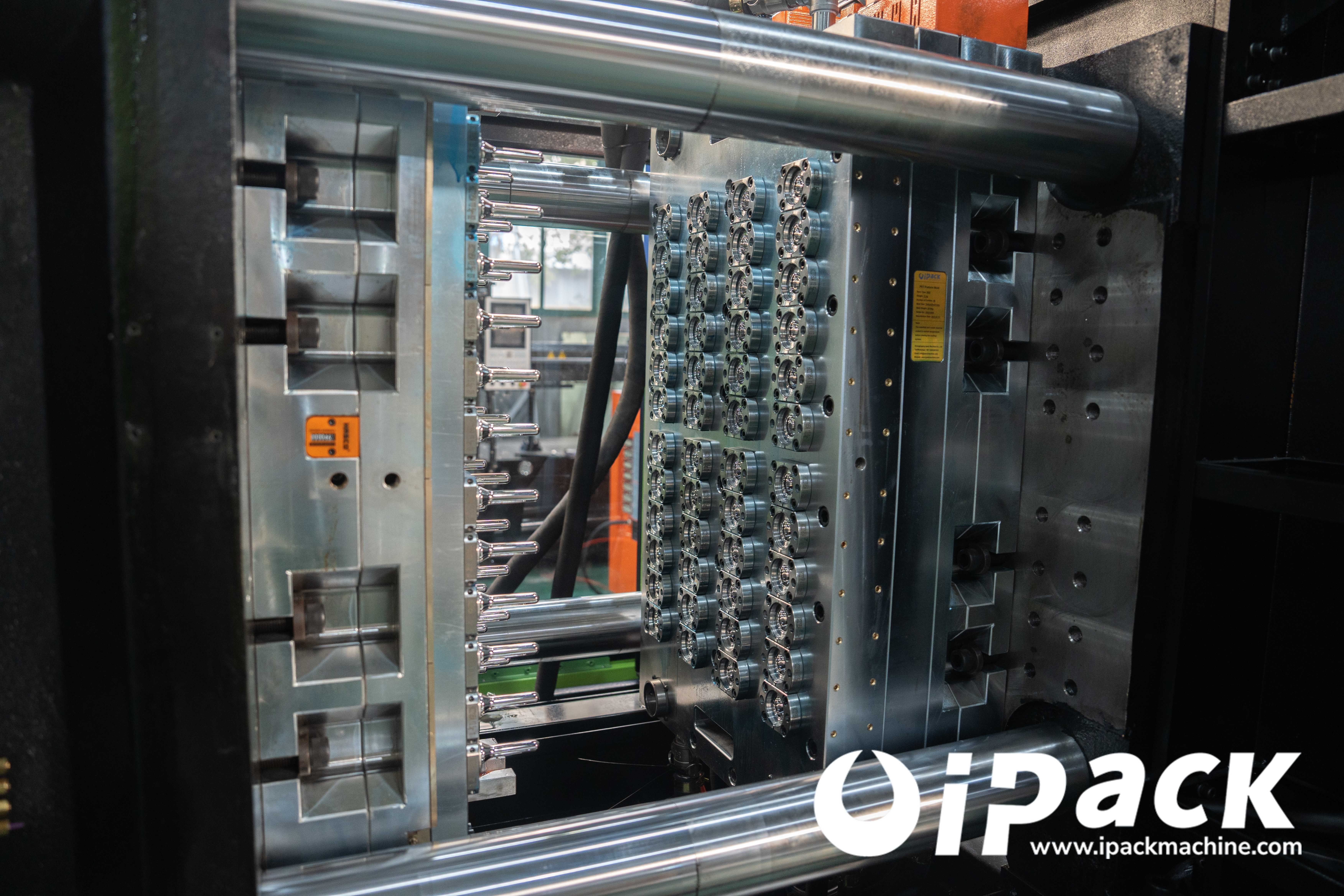

Clamping Unit

Injection Unit

BaIanced double injection cylinder technology makes screw to have evenly distributed force during fast injection,

Five_star Hydraulic motor with big torque, Ensure the excellent plastic molding condition. Research and develop different screws according to difierent iniection condition, suitable for the progressive demand and greatly improve the injection quality.

Control Unit

Imported computer special for Injection Molding Machine with multiple functions and precise control processing.

World famous electrical components and high quality circuit hardware with stable and reliable running.

World famous electrical components and high quality circuit hardware with stable and reliable running.

Application :

Injection Molding Machine can have a molding complex, the size is accurate or plastic with metal insert of the fine and close texture, are widely used in national defense, electrical, automotive, transportation, building materials, packaging, agriculture, Medical, Household, Appliance sectors and People's Daily life. Today with the rapid development of plastic industry, injection molding machine no matter in quantity or variety occupies an important position.

Hot Searches