- Product Details

- {{item.text}}

Quick Details

-

Drilling Speed:

-

5-500mm/min

-

Place of Origin:

-

Shandong, China

-

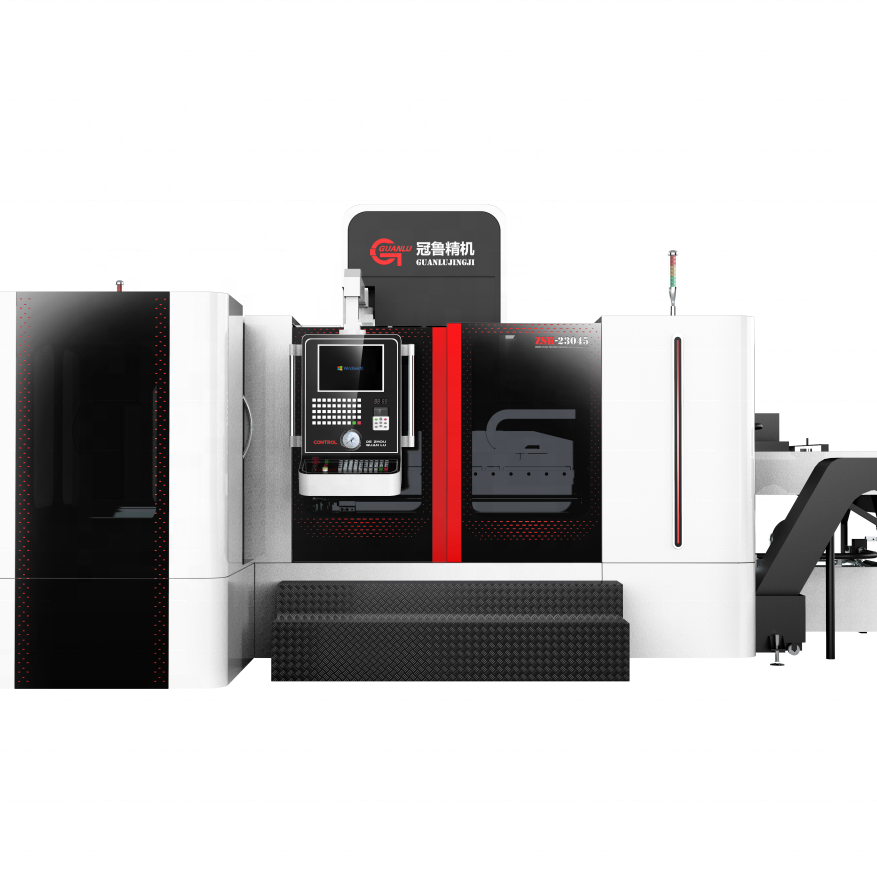

Brand Name:

-

Guanlu

-

Model Number:

-

ZSK2303*1500

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

6300x4500mm

-

Power (kW):

-

26KW

-

Weight (KG):

-

14 KG

-

Applicable Industries:

-

Metal, Three coordicate deep hole drilling machine has th, hydraulic valve body,

-

Marketing Type:

-

Other

-

Product name:

-

Three axis gundrilling

-

Drilling diameter range:

-

35mm

-

Drilling depth:

-

1m-3m

-

Control system:

-

GSK FANUC OR SIEMENS

-

Axis:

-

xyz

-

Main spindle tape:

-

BT40

Quick Details

-

type:

-

EDM Drilling Machine

-

Max. Drilling Dia. (mm):

-

3-35mm

-

Range of Spindle Speed(r.p.m):

-

30 - 500 r.p.m

-

Drilling Speed:

-

5-500mm/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guanlu

-

Model Number:

-

ZSK2303*1500

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

6300x4500mm

-

Power (kW):

-

26KW

-

Weight (KG):

-

14 KG

-

Applicable Industries:

-

Metal, Three coordicate deep hole drilling machine has th, hydraulic valve body,

-

Marketing Type:

-

Other

-

Product name:

-

Three axis gundrilling

-

Drilling diameter range:

-

35mm

-

Drilling depth:

-

1m-3m

-

Control system:

-

GSK FANUC OR SIEMENS

-

Axis:

-

xyz

-

Main spindle tape:

-

BT40

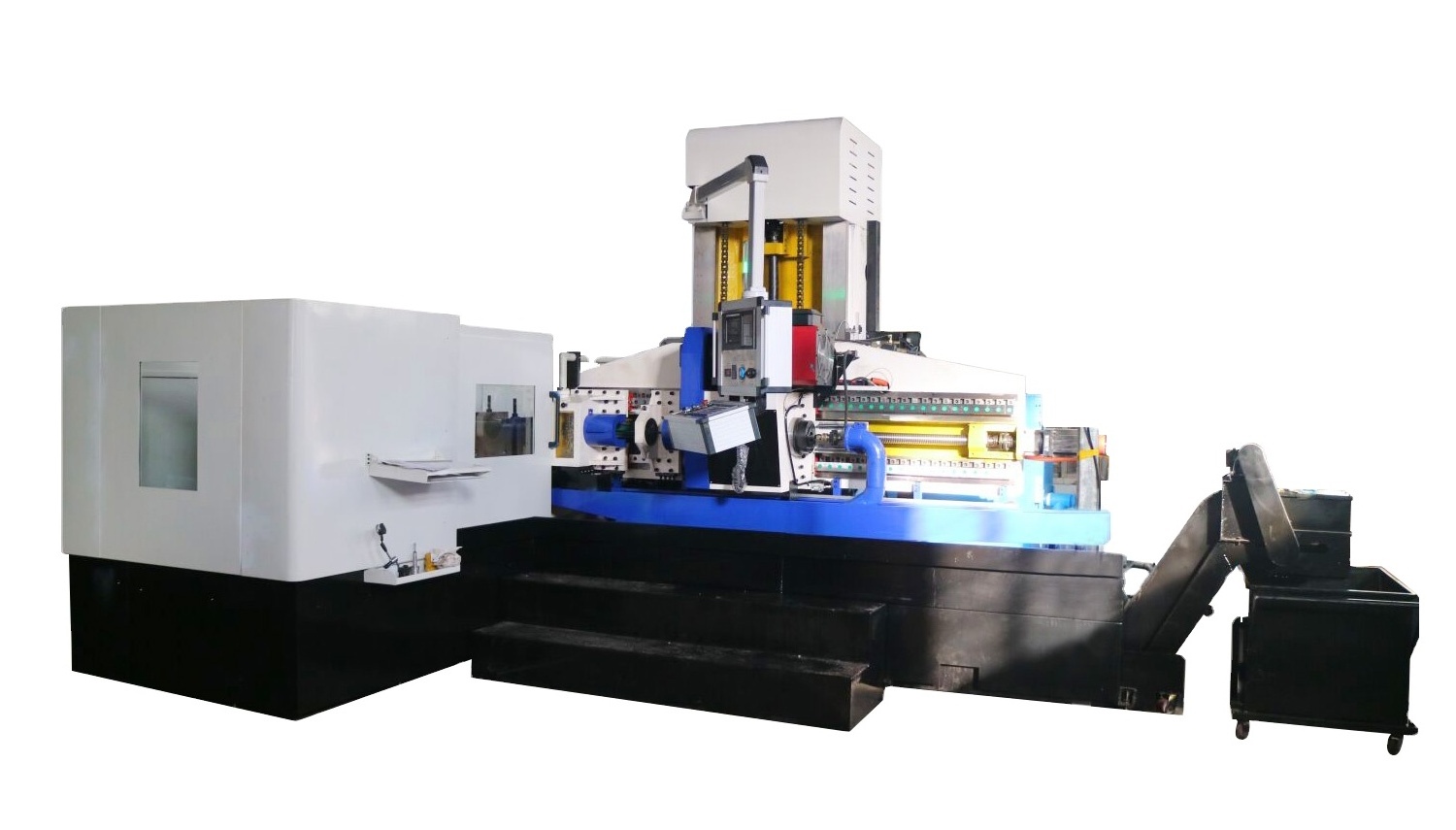

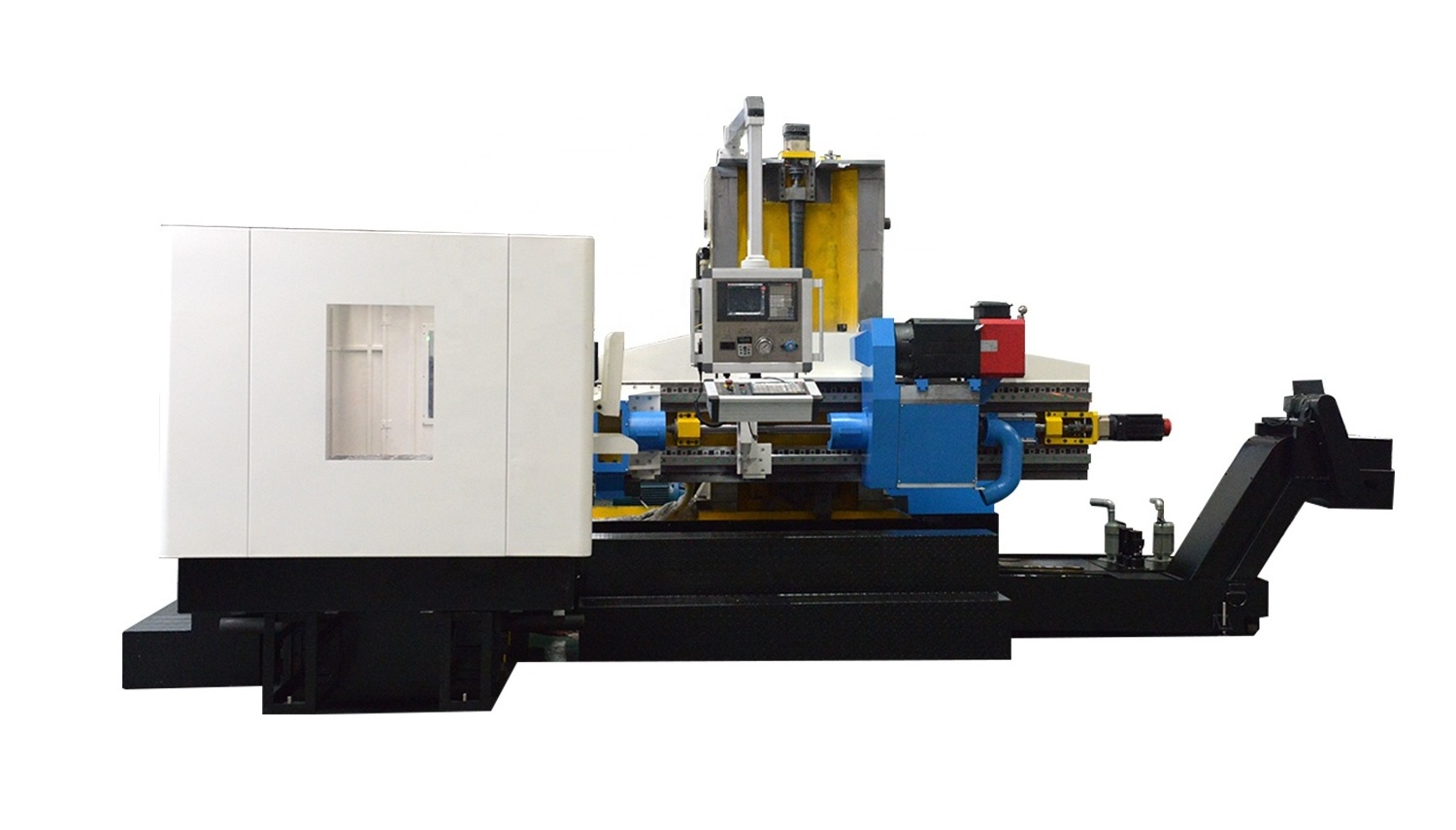

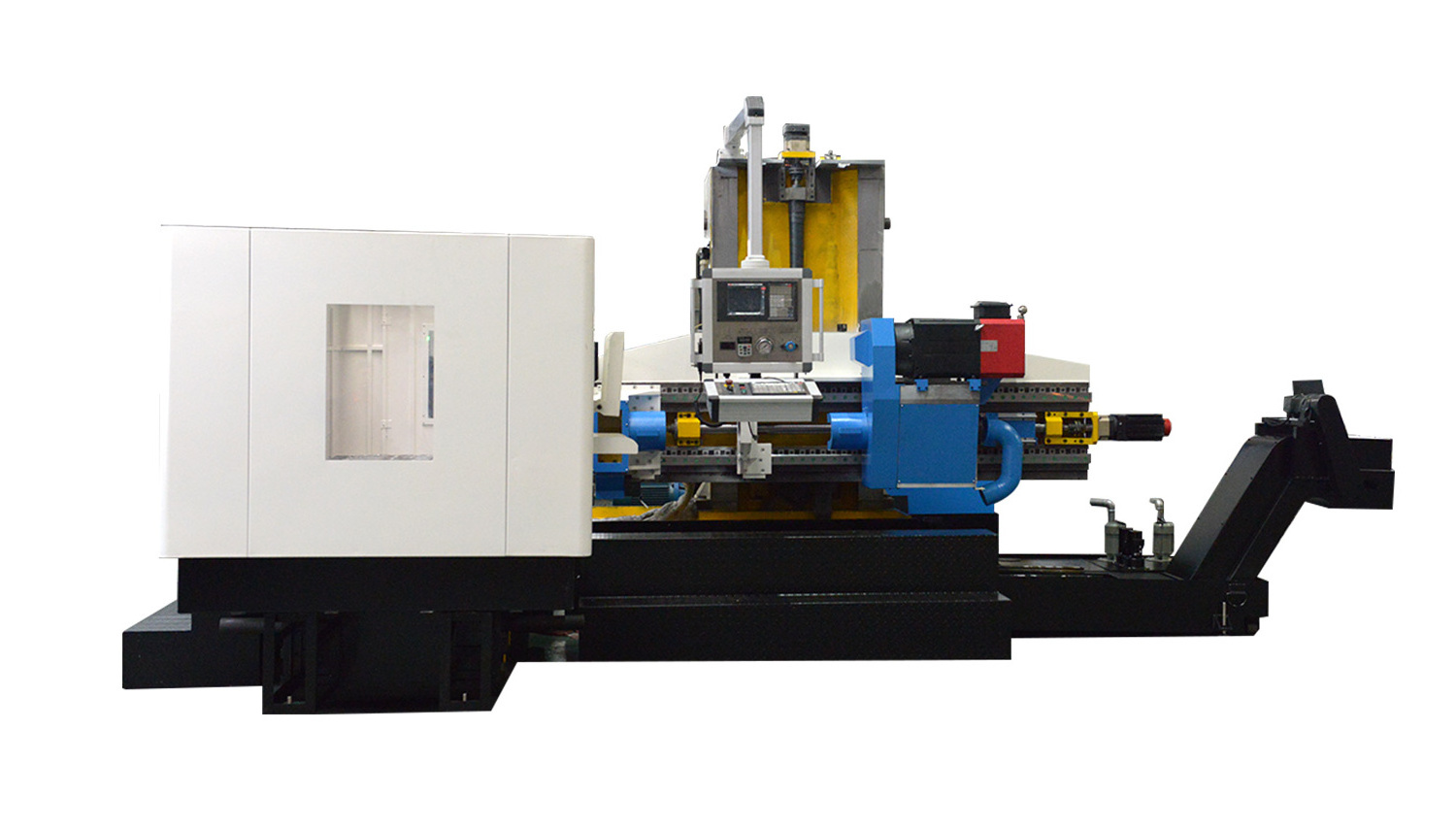

Three coordinate gun drilling machine :

It is widely used for molds industry. X,Y,Z axis are all controlled by CNC,so it is easy to drill the coordinate holes on the jobs.

This machine can be used in automobile, motorcycle, mold, military industry, aerospace industry, hydraulic valve body, gear shaft and other parts of small deep hole machining.

Mainly parts of three coordinate gun drilling machines:

-

X axis,Y axis,Z axis. The three axis are controlled by CNC controller.

-

Drill box

-

Working table ,customer could use index rotary working table.

-

Guide frame

The guide frame moves forward and backward along the rolling linear guide on the sliding block under the driving of the pneumatic system.,It has played the role of top tightening, loosening the workpiece and drill bit guidance, drill bar support and chip removal. -

Drill bar support: its function is to support drill pipe and reduce vibration.

-

Pneumatic system: It is used to control the movement of a guide frame.The gas source is provided by users,Pressure range is 0.5~0.6MPa.

-

Automatic lubrication system: Automatic timing and quantitative lubrication is adopted for the front and rear bearings, trailing bar guides, ball screws and nuts of the drilling box spindle. There are low oil level automatic alarm functions in the tank.

Hydraulic system: it is used to control clamping or loosening of CNC rotary worktable.

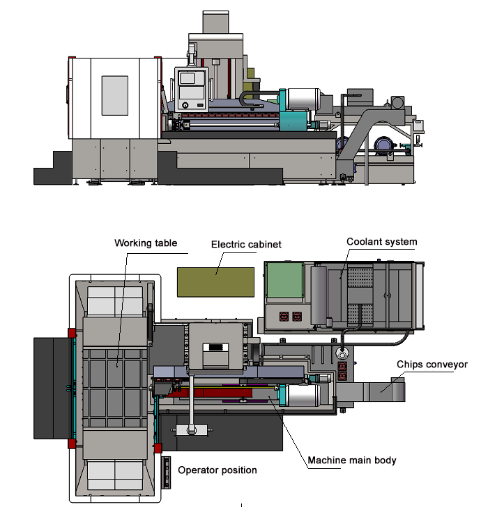

Machine drawing :

Machine parameter :

|

S pecification |

P arameter |

||

|

Working Capacity |

Drill hole diameter range |

Φ3~Φ3 5 mm |

|

|

Max . drill depth |

150 0 mm |

||

|

Machine Feature |

Xaxi s |

S troke |

150 0 mm |

|

Rapid move speed |

3 000 mm / min |

||

|

Motor torque |

18N m |

||

|

Yaxi s |

Rapid move speed |

3 000 mm / min |

|

|

S troke |

100 0 mm |

||

|

Motor torque |

2 2 Nm |

||

|

Z axis |

Rapid move speed |

5 000 mm / min |

|

|

Feeding speed range |

5-500 mm / min |

||

|

Motor torque |

10N m |

||

|

Drill box |

Max . Rotary speed |

6000 r / min |

|

|

Motor power |

7. 5 kw |

||

|

Working table |

Size ( Xx Z ) |

1800 x 1200 mm |

|

|

Working table load |

6T |

||

|

Coolant system |

Max . Pressure |

1 0 MPa ( Adjustable ) |

|

|

Max . Flow |

100 L / min ( Adjustable ) |

||

|

Filter accuracy |

2 0 μm |

||

|

O t hers |

Machine total power ( roughly ) |

2 6 KW |

|

|

Floor size ( L x W ) |

6 300 x 4500 mm |

||

|

Machine total weight ( roughly ) |

1 4T |

||

Machine photos for reference ONLY :

Customer keeping visiting