- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

4000 kg, 4000-26000kg

-

Capacity:

-

35-500t

-

Height:

-

13-23m

-

Application:

-

Bulk material for batching plant

-

Service life:

-

10 years

-

Color:

-

As customers' requirement

-

Thickness of plate:

-

4mm

-

After Warranty Service:

-

Spare parts and online supporting

-

Style:

-

Bolted or Horizontal

-

Storage Materials:

-

Cement, fly ash, etc.

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chenli

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

4000 kg, 4000-26000kg

-

Capacity:

-

35-500t

-

Height:

-

13-23m

-

Application:

-

Bulk material for batching plant

-

Service life:

-

10 years

-

Color:

-

As customers' requirement

-

Thickness of plate:

-

4mm

-

After Warranty Service:

-

Spare parts and online supporting

-

Style:

-

Bolted or Horizontal

-

Storage Materials:

-

Cement, fly ash, etc.

Stable Powder Storage Silo 120t Cement Silo for Batching Plant

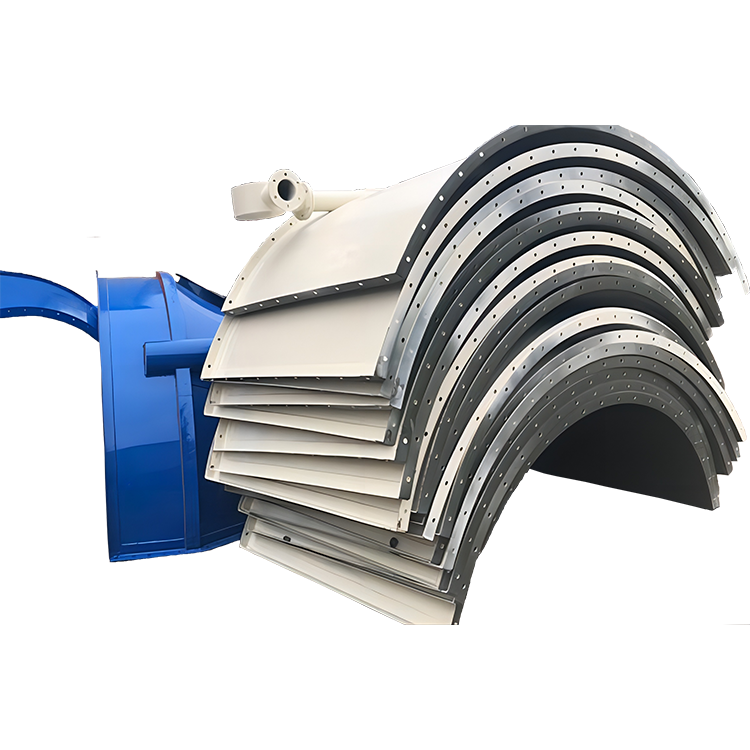

Powder storage silo

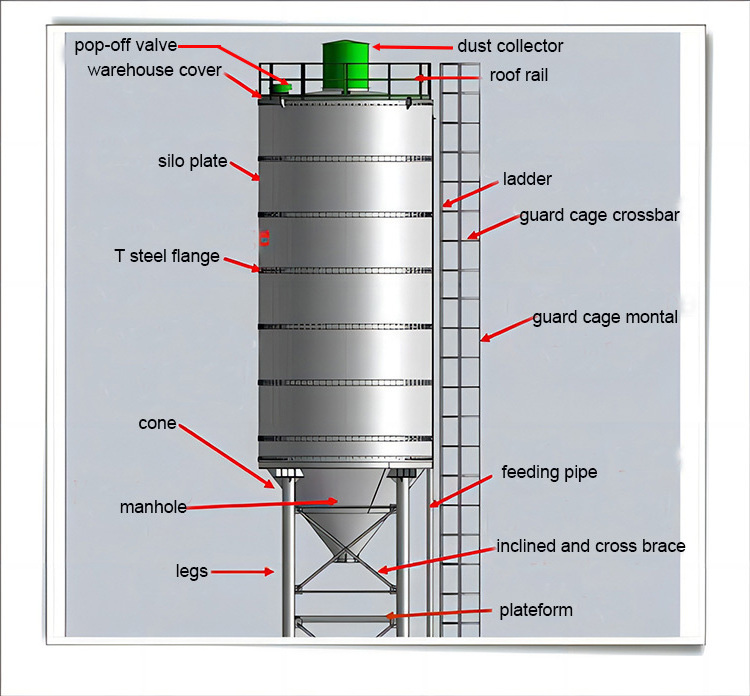

is a closed tank for storing bulk materials. It is suitable for storing various bulk materials such as cement and fly ash. The silo is combined by four main parts: the cover, wall sections, cones and supporting legs. All parts are pressed by special machine and mould, especially the wall section which can be changed every place on the wall.

Working principle

When installing the powder storage silo, it must be erected with a special crane and then placed on the precast concrete foundation. The verticality of the powder storage silo to the horizontal plane after erection must be checked. The bottom of the powder storage silo and the embedded parts of the foundation are welded firmly.

After the silo is fixed, the bulk cement truck transports the cement to the construction site, and then connects the delivery pipeline of the bulk cement truck with the feed pipe of the powder storage silo. The cement in the tank of truck will be transported to the powder storage silo by air pressure from the bulk cement truck. During the process of transporting cement to the silo, the operator should constantly press the button of the vibration motor of the dust collector to shake off the cement attached to the dust collector bag to prevent the bag from clogging and the silo bursting.

Once the bag is clogged and the pressure in the warehouse exceeds the safety pressure of the pressure safety valve on the top of the warehouse, the pressure safety valve will open to release the pressure in the warehouse to prevent explosion accidents. Through the high and low material levels, you can observe whether the warehouse is full of materials or lack of materials. When it is necessary to unload, first open the manual unloading valve at the bottom of the cone, and then transport the cement through the cement conveying device. During the discharging process, if "bounce" occurs, promptly press the solenoid valve button of the arch breaking device to blow air to eliminate the "bounce" of the feed and ensure smooth cement supply.

| Volume | Diameter | Silo body height | Layers of silo body | Pieces each layer | |

| 50t | 3160mm | 4260mm | 3 | 4 | |

| 100t | 3160mm | 8700mm | 6 | 4 | |

| 150t | 3160mm | 13000mm | 9 | 4 | |

| 200t | 4000mm | 11360mm | 8 | 5 | |

| 200t | 4500mm | 8700mm | 6 | 6 | |

| 300t | 5300mm | 8700mm | 6 | 8 | |

| 500t | 6800mm | 7300mm | 8 | 8 | |

| 600t | 6800mm | 8700mm | 6 | 8 | |

| 800t | 8000mm | 10100mm | 7 | 10 | |

| 1000t | 8000mm | 13200mm | 9 | 10 |

The parameters in the table are incomplete. Click here for more information.

1. Flexible transportation, saving freight, reaching all over the world.

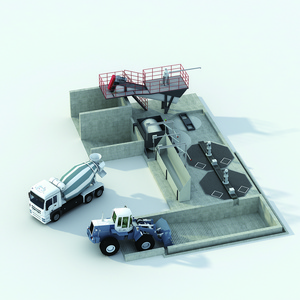

powder storage silos are generally used to store bulk cement and other powders in concrete batching plants. They are an important part of concrete batching plants.

Tai'an Chenli Construction Machinery Co., Ltd. is a technology-based company focusing on the development, design, manufacturing, engineering and service of intelligent complete equipment for building materials. Based on a deep understanding of building intelligent equipment, Taian Chenli is committed to providing users with "practical, efficient, low-carbon, environmentally friendly, intelligent and advanced" intelligent equipment products. In line with the product concept of "excellence in quality, simplicity to the extreme", committed to the high-tech development and application of intelligent equipment, energy-saving and environmentally friendly equipment for new building materials. The current leading products are cement concrete batching plants, mortar production lines, tower type sand making machine, and environmental protection equipment for batching plants. The products win the trust of the market with high standards and high reliability, and are deeply trusted by users.

Click Here to Contact Us