- Product Details

- {{item.text}}

Quick Details

-

color:

-

up to you

-

product quality:

-

accord with industrial standard

-

technical support:

-

supply by us

-

after sale service:

-

the whole using life

-

operation:

-

continuous and stable .

-

Motor:

-

China Famouse Kaifeng or Shandong brand

-

Test run:

-

Under our technician's guide

-

Installation:

-

Under our technician's guide

-

Certification:

-

ce iso

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support, Field maintenance and repair service, Engineers available to service machinery overseas

-

Material:

-

copper

-

color:

-

up to you

-

product quality:

-

accord with industrial standard

-

technical support:

-

supply by us

-

after sale service:

-

the whole using life

-

operation:

-

continuous and stable .

-

Motor:

-

China Famouse Kaifeng or Shandong brand

-

Test run:

-

Under our technician's guide

-

Installation:

-

Under our technician's guide

-

Certification:

-

ce iso

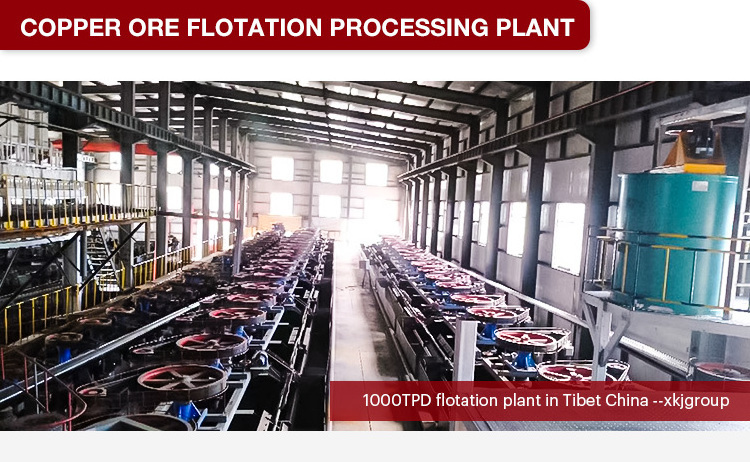

I . COPPER ORE FLOTATION PROCESSING PLANT

According to the differences of physical and chemical properties of copper ore surface, copper ore flotation production line is treated by flotation reagents, the copper deposits are selectively stick to the bubbles for the purpose of separation.

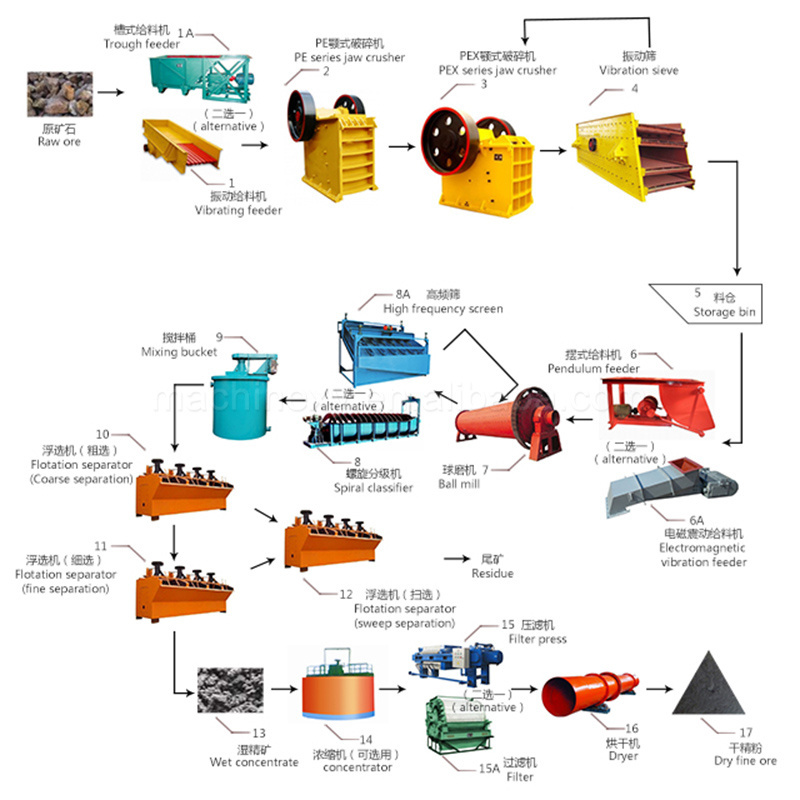

Copper flotation process is divided into several parts, such as crushing, grinding and flotation etc.It will be used jaw crusher, ball mill, spiral classifier, flotation machine, the mixing tank, thickener and other equipment.

II . APPLICATION SCOPE

Vein copper ore; Sulfide copper ore.In addition to separate copper, the process can also be used for flotation of copper ore, lead and zinc ore, fluorite ore, feldspar ore, graphite ore, tungsten ore and other metals and non-metal ore.

CUSTOMER CASE 1: 600TPD copper ore flotation plant customer case

In 2017, our factory and the South African customer reached an EPC project contract of copper ore beneficiation project. The project designed capacity is 180,000 tons per year, 600 tons per day and 300 working days per year. Although the copper grade of the mine (5-13%) is not low, the complex mineral composition has become one of the difficulties of the project.

After a comprehensive analysis of test and experiment, mechanical engineers of Xingyang Mining Machinery Manufactory determined the multi-stage grinding and flotation mixed dressing method, specific include: three-stage of grinding, a roughing, secondary scavenging, and fifth concentrating .

After processing, the copper ore grade of from original 5% - 13 % increased to 90% of concentrate. The main equipment of this project includes: jaw crusher, ball mill, spiral classifiers, flotation machine, thickener, mixing tank and other equipments.

CUSTOMER CASE 2: 500TPD Copper ore flotation plant customer case

The Nissan 500-ton copper ore beneficiation equipment project is the EPC project contracting project signed by our factory and Mexico. The flotation method is used to select the copper mine: the qualified materials ground by the ball mill are treated by stirring, flotation, concentration, filtration and other equipment. , select qualified copper concentrate. With the normal design, production, inspection, and delivery of the equipment, our factory began to send workers for follow-up installation guidance and operational guidance.

Henan Xingyang Mining Machinery Manufactory, is a large sized joint-stock enterprise integrated with the scientific research,production and sales of heavy mining machinery. The company have five standard heavy industrial workshops covering 80,000 square meters,more than 160 machines used for gold processing,plug welding and assembling with large and medium sizes, and more than 500 works including over 50 administrators with intermediate and senior title and engineering technicians.

Q1: Hi, are you mining machinery manufacturer?

A1: Yes, we can also provide amples test, mine design, equipment manufacture, after-sale service, etc.

Q2: Which country have your products been exported?

A2: Many countries,such as India, Sudan, South Africa, Zambia, Congo, Ethiopia, Iran, Kenya, Mexico, Canada, the United States, Morocco, etc.

Q3: Can you do mineral processing test?

A3: Yes, not only do it in your country, but also back to our company.

Q4: Can you provide me a solution and quotation?

A4: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.