- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vacorda

-

Model Number:

-

UHC

-

Material:

-

Stainless steel, PP, PTFE, 304, 316L...

-

Mode:

-

Bypass level gauge

-

Measuring range:

-

200~6000mm

-

After service:

-

18 months

-

Delivery:

-

3~15 days

-

Life Span:

-

5-10 Years

-

Name:

-

Manufacturer of Magnetic Float Ball Water Level Gauge

-

Origin:

-

Sichuan, China

-

Brand:

-

Vacorda

-

Specification:

-

Standard and customized

-

Payment terms:

-

T/T, L/C, moneygram, western union, cash...

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 Year

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Vacorda

-

Model Number:

-

UHC

-

Material:

-

Stainless steel, PP, PTFE, 304, 316L...

-

Mode:

-

Bypass level gauge

-

Measuring range:

-

200~6000mm

-

After service:

-

18 months

-

Delivery:

-

3~15 days

-

Life Span:

-

5-10 Years

-

Name:

-

Manufacturer of Magnetic Float Ball Water Level Gauge

-

Origin:

-

Sichuan, China

-

Brand:

-

Vacorda

-

Specification:

-

Standard and customized

-

Payment terms:

-

T/T, L/C, moneygram, western union, cash...

Stable Anti-explosion Fuel tank Float Ball Level Switch

Magnetic level sensor consists of reed, precise resistance and amplification transformation circuit and adopt imported advanced sensor componentsand signaltransmitters. When the magnetic lineof themagnetic float ball reaches a certainplace ofthe levelsensor, the reed closes, andthe floatball changeswith theheight of level interface. The amplification transformation circuit converts the change of the interface height into linear 4~20mADC signal to realize the measurementand transmissionof thelevel locationsignal.

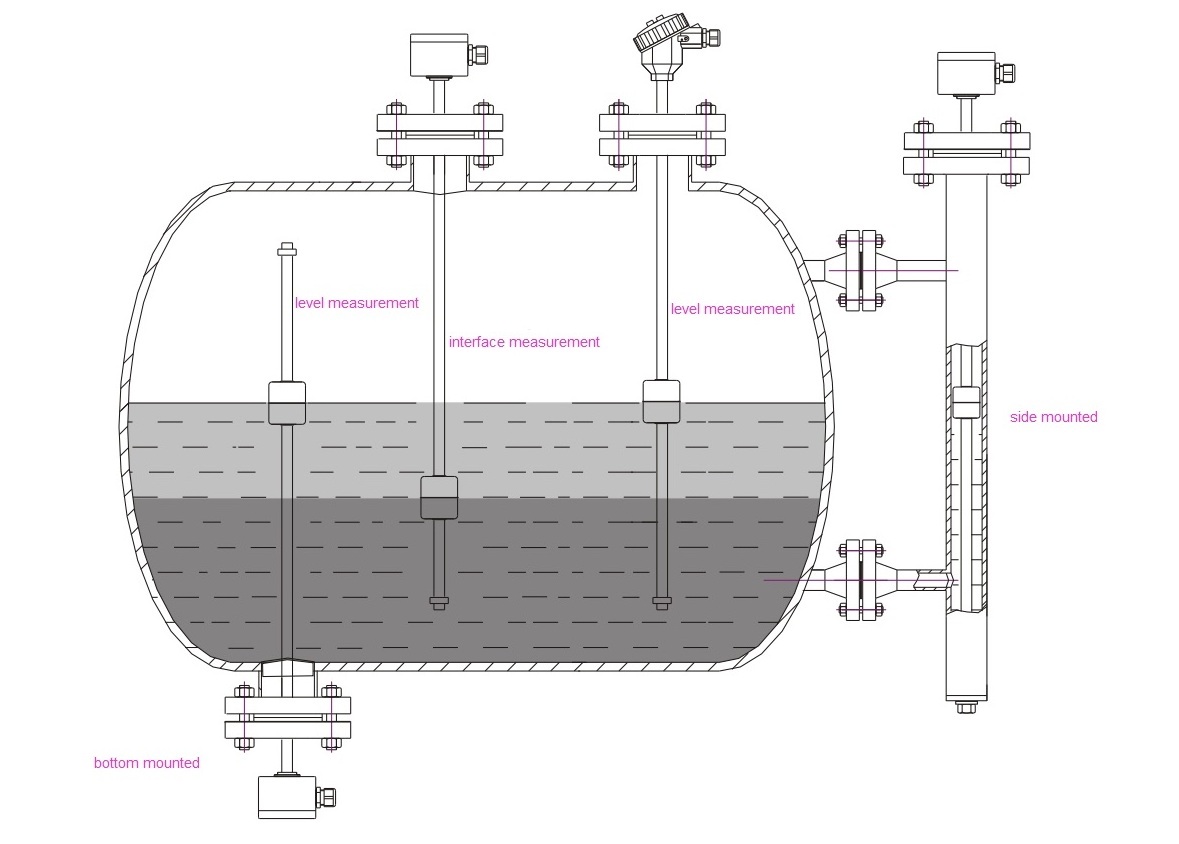

Product installation

Pruduct features

1. Simple structure, good stability and reliability.

2. Independent of medium’s physical and chemical states such as conductivity, dielectric constants, foam etc.

3. Appliable for all kinds of medium environment such as corrosive, toxic and explosive one.

4. Interface measurement or level measurement of 2 kinds of medium with different density.

5. Two-wire 4~20mADC signal output, 0.8’’ or 0.56” LED digital display.

6.Explosion-proof structure design for exploding environment

Product Parameters

| Measuring range | 200~6000mm(>6M customize) |

| Resolution factor | 10mm,5mm,20mm |

| singal output |

4~20mA(two-line) 2000/m(1/2",3/8") |

| Loading resistance | 500Ω |

| Transmitting | > 1000m |

| Working power supply | 16~30VDC |

| Density | ≥ 0.5g/cm 3 |

| Pressure | PN2.5~PN160(×0.1MPa)(Max pressure PN320) |

| Operating temperature | -40 ~ 80 °C, ≤ 120 °C, ≤ 150 °C |

| Float ball diameter | Φ30~Φ120 ( depending on pressure and density ) |

| Flange installation |

DN40~DN150/RF/PL(HG/T20592~2009)

customize

2'' thread(downward install) 1/2'' thread (upward install, resistance signaloutput) 3/8'' thread(upward install, resistance signal output) |

| Installation angle | ≤ ±25° |

| Electrical connection |

M20×1.5 female thread Three-lines screening cable |

| IP grade | IP65 |

| Explosion-proof grade | Exia II CT6Ga,EXd IICT6Gb |

Product Application