- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

5.5

-

Product name:

-

tyre tread making machine

-

Keywords:

-

rubber vulcanizing press

-

Function:

-

making tyre tread

-

Heating:

-

Oil Steam

-

Operate:

-

Easy

-

Capacity:

-

20000-30000PCS/Day

-

Model:

-

XLB-DQ

-

Certification:

-

CE BV ISO

-

Control:

-

Full-automatic

-

Quality:

-

High-Quality

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V

-

Weight:

-

4.5

-

Power (kW):

-

5.5

-

Product name:

-

tyre tread making machine

-

Keywords:

-

rubber vulcanizing press

-

Function:

-

making tyre tread

-

Heating:

-

Oil Steam

-

Operate:

-

Easy

-

Capacity:

-

20000-30000PCS/Day

-

Model:

-

XLB-DQ

-

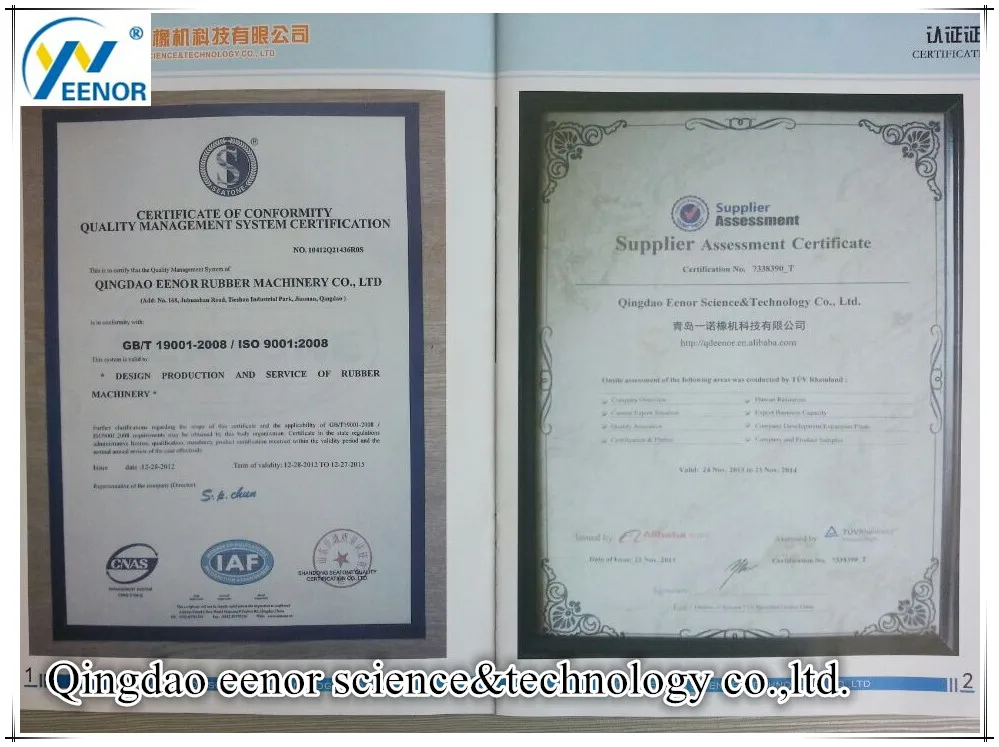

Certification:

-

CE BV ISO

-

Control:

-

Full-automatic

-

Quality:

-

High-Quality

Tyre Patch Making Machine

If you're looking to customize arubber tread vulcanizingmachine, there are severalaspects you can consider basedon your specific requirements.Here are some areas you canfocus on for customization:

1. Size and Capacity:Determine the size andcapacity of the machinebased on the volume ofrubber treads you intend toproduce. Consider factorssuch as the width andlength of the treads, as wellas the desired productionoutput.

2. Heating System: The heatingsystem is crucial forvulcanization. You cancustomize the heating elements to ensure efficientand uniform heatdistribution across therubber treads. Options mayinclude electric heaters,steam heating, or hot oilcirculation systems.

3. Control System: Choose a

control system that providesprecise control overtemperature, pressure, andduration of the vulcanizationprocess. This can beachieved through digitalcontrollers withprogrammable settings andsensors for monitoring andmaintaining the desiredparameters.

4. Conveyor System:Customize the conveyor system to accommodate thesize and weight of therubber treads. Considerfactors such as belt material,speed adjustmentcapabilities, andmechanisms for loading andunloading the treads.

5. Safety Features: Incorporateessential safety features,such as emergency stopbuttons, safety interlocks,and protective guards, toensure the well-being ofoperators and preventaccidents during operation.

6. Automation and Integration:Depending on yourproduction requirements,you may want to considerautomating certain processes or integrating thevulcanizing machine withother equipment, such asrubber mixing or cuttingmachines, to streamlineproduction and increaseefficiency.

7. Energy Efficiency: Optimizethe machine's energyconsumption byincorporating energy-efficient components andinsulation materials. Thiscan help reduce operatingcosts and environmentalimpact.

8. Maintenance andServiceability: Design themachine with ease ofmaintenance in mind.Consider access points for cleaning, replacing parts,and performing routinemaintenance tasks.Incorporate diagnosticfeatures to aid introubleshooting andpreventive maintenance.

9. Compliance andCertification: Ensure that themachine meets safety andregulatory standardsrelevant to your industry andlocation.

This includecertifications like CE, , ISO standards.

To customize a rubber treadvulcanizing machine, it'sadvisable to consult with areputable manufacturer orsupplier who specializes in supplier who specializes inrubber processing equipment.They can provide expertguidance and tailor the machineto your specific needs,considering factors such asbudget, production volume, andindustry requirements.

Frank Zhang

Sales Manager

Mobil: 0086-17685519888 (wechat/whatsapp)

| Type | XLE-Q 3600*410 | XLE-Q 5000*670 |

| Total Pressure (mn) | 5.00 | 8.00 |

| Plate Size (mm) | 3600*410 | 5000*670 |

| Plate clearance (mm) | 200 | 200 |

| piston diameter (mm) | 5*285 | 8*285 |

| work pressure (mpa) | 15 | 15 |

| steam pressure (mpa) | 1.0 | 1.0 |

| Motor power (kw) | 7.5+5.5 | 5.5+11 |

| Operation mode | PLC system | PLC system |

| Heating mode | electric/steam,oil heating | electric/steam,oil heating |