- Product Details

- {{item.text}}

Quick Details

-

Technology:

-

thermal spray

-

Kinds of coating:

-

Metallic

-

Equipment Name:

-

Spray Coating Line

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Application:

-

automobile engine cylinder cover field

-

Usage:

-

improve wear resistant ,corrosion resistant

-

Technology:

-

thermal spray

-

Kinds of coating:

-

Metallic

-

Equipment Name:

-

Spray Coating Line

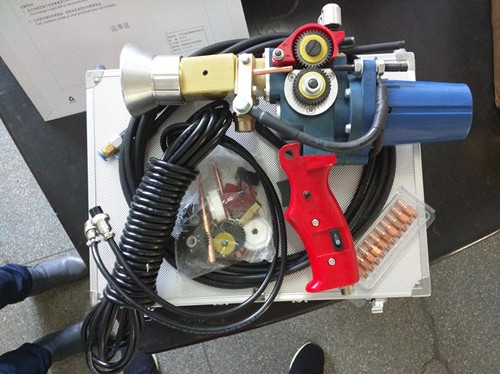

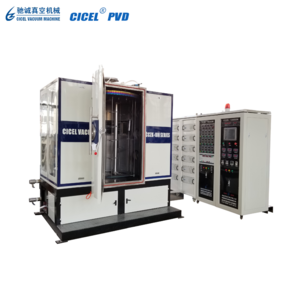

Metallisation Metallisation’s thermal spraying equipment,Multi arc vacuum pvd chrome spray machine

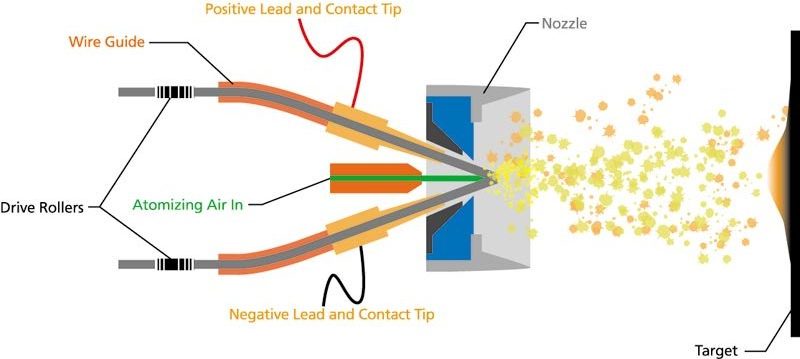

Arc spray (sometimes referred to as twin wire arc spray) is a process that uses an electric arc to melt wires. The molten metal is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed.

Anti-corrosion or engineering coatings can be applied by arc spray and changing between the two is quite simple. Arc spray systems are commonly considered to be easy to operate and also to automate.

The arcspray process

The spray rate and pistol are easy to control, also making it suitable for spraying more intricate areas like deck rails and hardware. The coating finish is very fine, which creates an ideal base for the final paint top coats. In the Arcspray process, two electrically charged wires are driven and guided so that they converge at a point and form an arc. An air nozzle atomises the molten metal produced from the wire and projects it towards the work piece using high pressure air. This spray solidifies when it hits the surface of the work piece to form a dense coating, which protects against corrosion. The driving of the wires is typically either by air motor or electric motor and gearbox arrangement.

1. Main technical parameter of Thermal Arc Spray/metal Arc Spray Machine,Metal Arc Spray

|

Spray material |

Wire diameter |

Working current |

No-load volt |

Air hat diameter |

Maximum spray efficiency |

|

Zinc wire |

1.2-3.0 |

80-210 |

18-30 |

6-8 |

30 |

|

Al wire |

1.2-3.0 |

120-240 |

25-38 |

6-8 |

9.5 |

|

Steel wire |

2.0 |

150-200 |

35-40 |

7-8 |

6 |

|

High carbon steel wire |

2.0 |

150-220 |

10-44 |

8 |

5.5 |

|

Stainless steel wire |

2.0 |

150-220 |

10-44 |

8 |

5.5 |

|

Zn-Al, Pb-Sn alloy wire |

1.2-2.0 |

80-110 |

18-28 |

7 |

|

|

Air pressure |

Input power supply |

Output efficiency |

Output no-load volt |

Power supply weight |

Regulating volt |

|

>0.5Mpa |

Three phase 380V,50HZ |

16KW |

18-44V |

178kg |

0-24V |

|

Spray gun weight |

Air pressure |

Air consumption |

Wire feeding gravitation |

Velocity regulating range |

Input velocity |

|

2.65kg |

>0.5Mpa |

>1.85m 3 /min |

>8kg |

stepless speed regulating |

24V(DC) |

Application:

Metallisation have a full range of arc spray systems for hand-held and fully automatic / robotic applications

Characteristic:

The advantage of Electric wire arc spray gun, Thermal spray wire spray machine, Pull or Push type Arc spray machine gun

(1) Stable and convenient

(2) High bond strength of coating

(3) Workpiece won’t deform and its structure won’t be influenced.

(4) High efficiency and wide range usage.

(5) Wide spray gun extending range and pull / push way of wire feeding to pick

(6) No need to change wearing parts frequently

(7) Convenient maintenance and repair.

Certificate of proudcts:

Company view:

Customers:

Package:

Contact information

We have devoted to thermal spray technology since 1989.You are assured to get the best solution.FAQ as follow please:

1. What kind of products will you want to spray ? --- Could you provide some pictures?

2. Which material will you want to use? wire or powder?(zinc wire,alumium wire,stainless wire ,copper wire ,gold wire ,tugesten carbide power ,ceramic powder and so on)

3. Which effect will you want to get ? High temperature resisting ,wear resisting or anticorrosion ,reparing work or others?

4. Do you have any other technical requirements? the more the better.