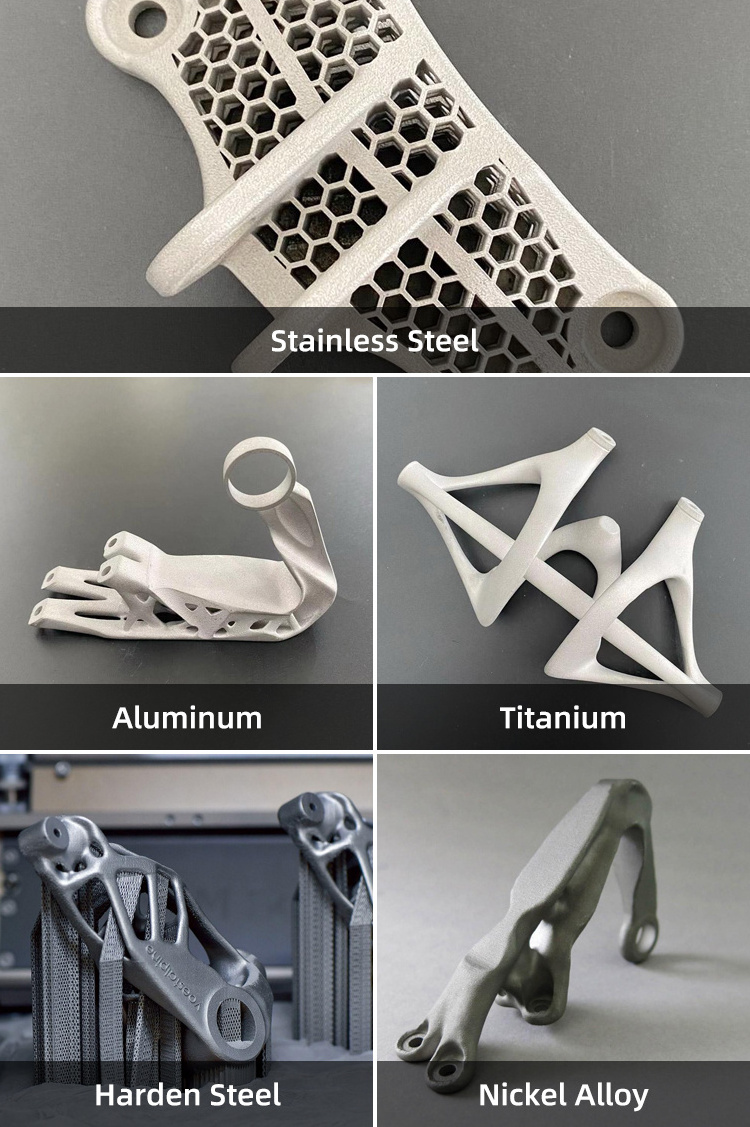

Direct Metal Laser Sintering (DMLS) is a metal additive manufacturing processes that belong to the powder bed fusion 3D printing family, using laser to scan and selectively fuse (or melt) the metal powder particles, bonding them together and building a part layer-by-layer. Also, the materials used in the processes are metals that come in a granular form.

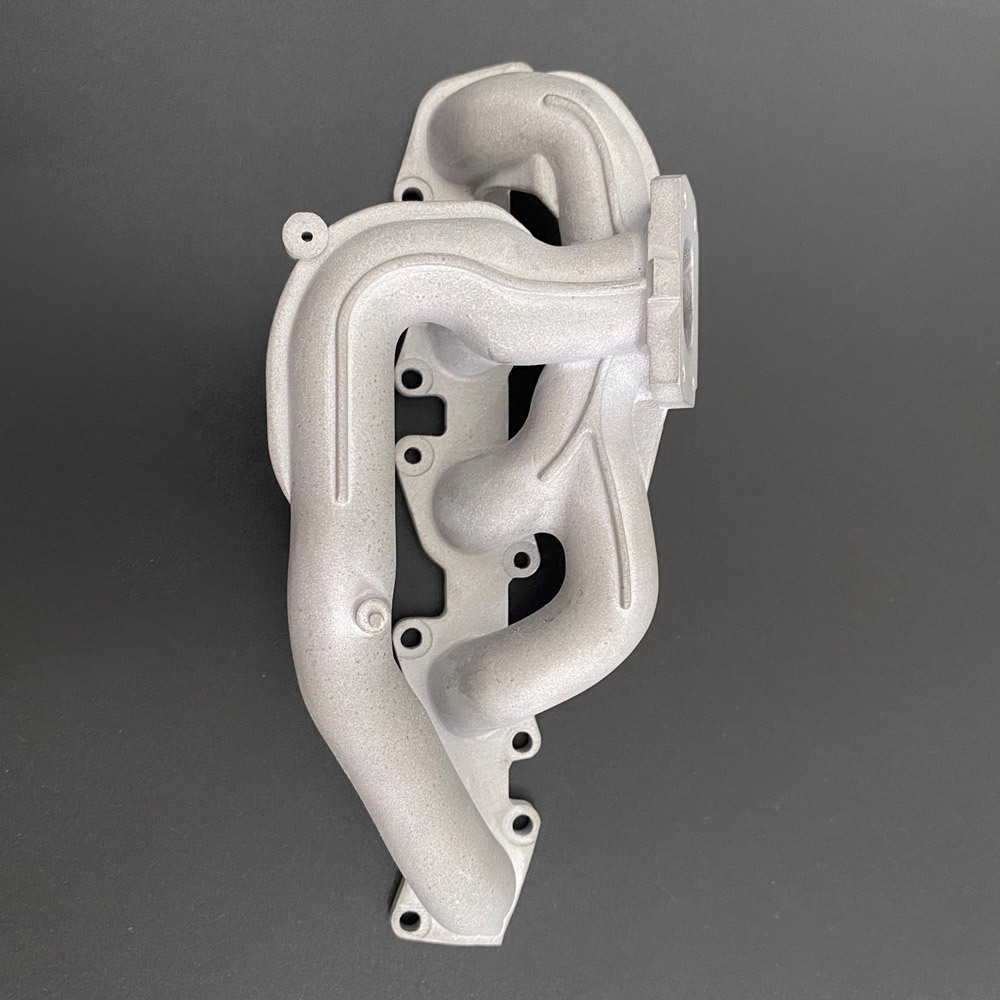

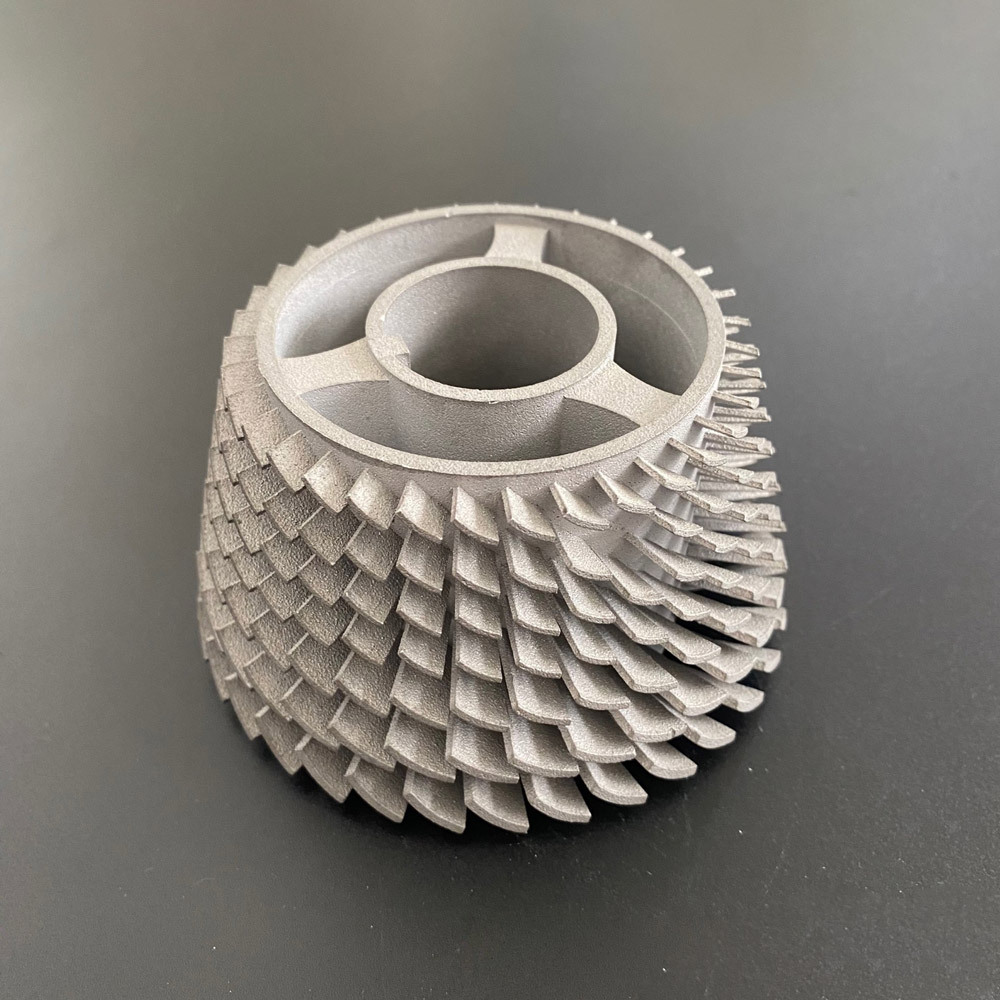

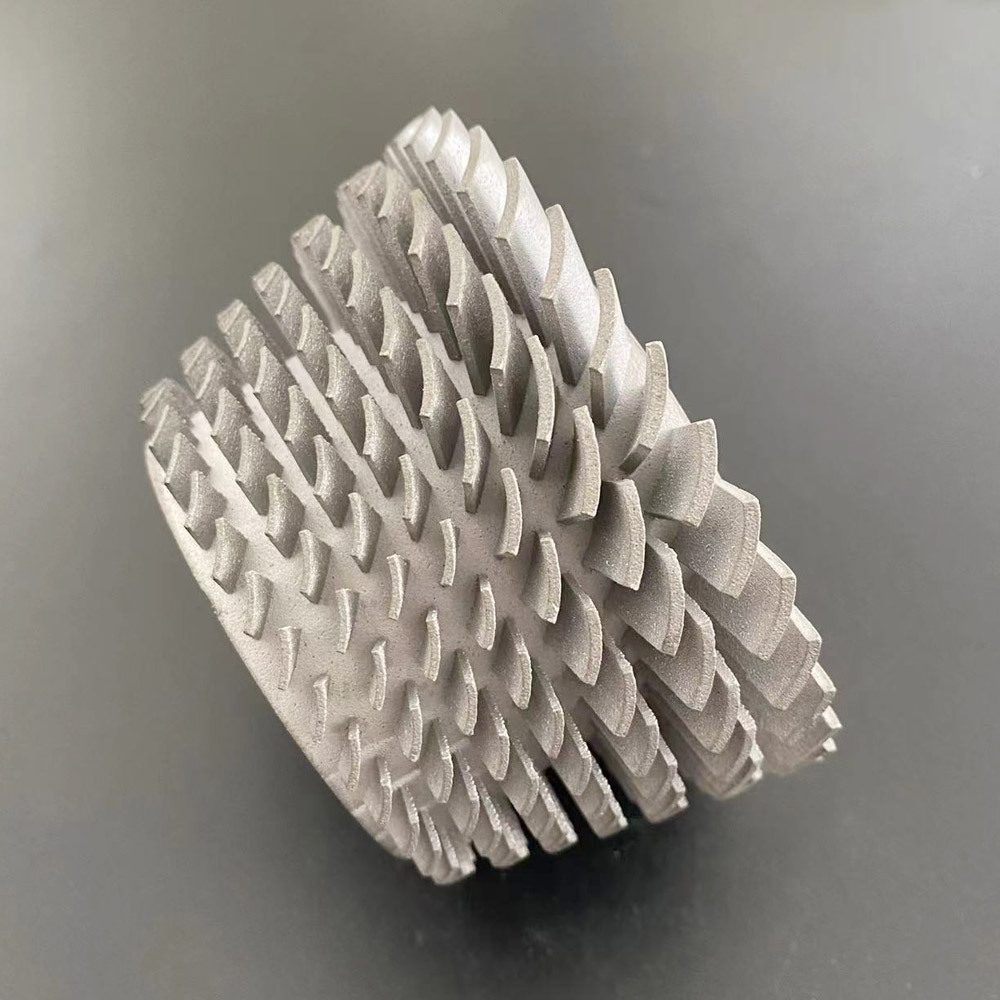

DMLS / SLM 3d printing service belong to the powder bed fusion 3D printing family. The two technologies have a lot of similarities: both use a laser to scan and selectively fuse (or melt) the metal powder particles, bonding them together and building a part layer-by-layer. Also, the materials used in both processes are metals that come in a granular form. Designers often chose DMLS for its ability to produce all-in-one metal assemblies and highly precise metal parts with complex features like internal supports and lattices.

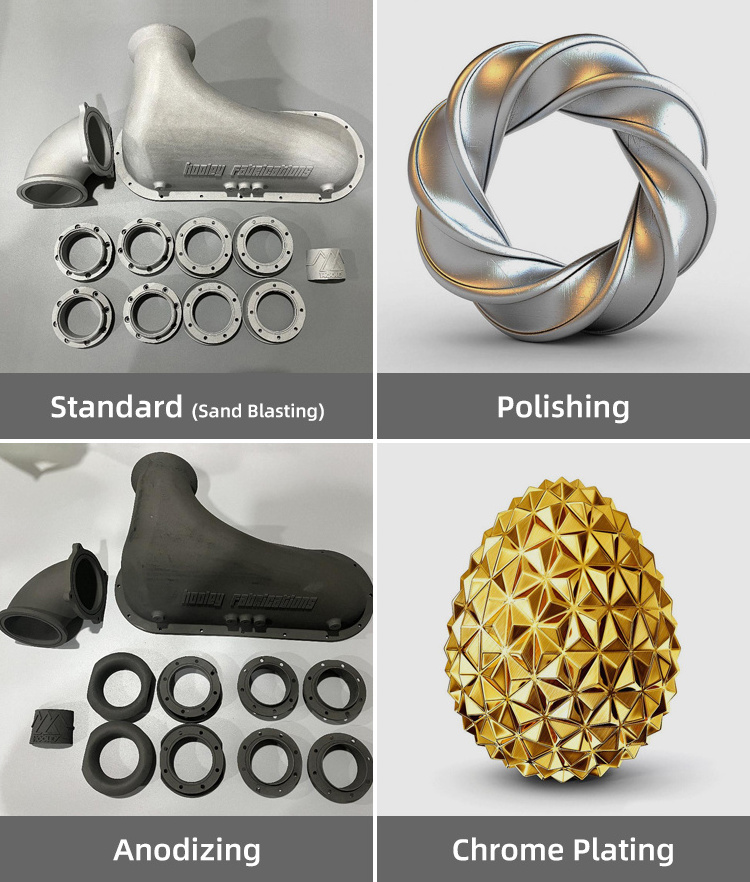

DMLS does not have upfront setup or tooling costs, making it an affordable option for fully dense metal parts, with the design freedom of additive manufacturing.

With DMLS’s affordability, speed, and superior design freedoms, companies and creators can build metal designs they never thought possible and produce accurate metal components .

DMLS does not have upfront setup or tooling costs, making it an affordable option for fully dense metal parts, with the design freedom of additive manufacturing.

With DMLS’s affordability, speed, and superior design freedoms, companies and creators can build metal designs they never thought possible and produce accurate metal components .