- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

10

-

Weight (KG):

-

1100 kg

-

Panel Feed Speed(m/min):

-

15m/min

-

Name:

-

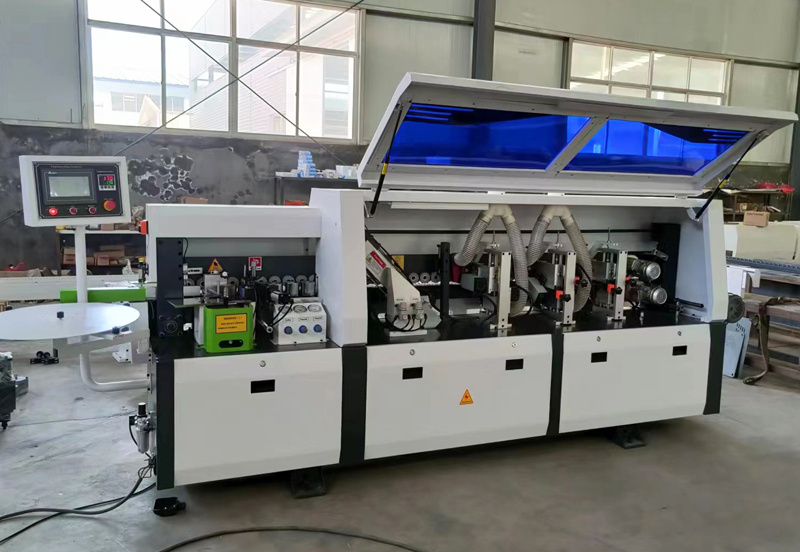

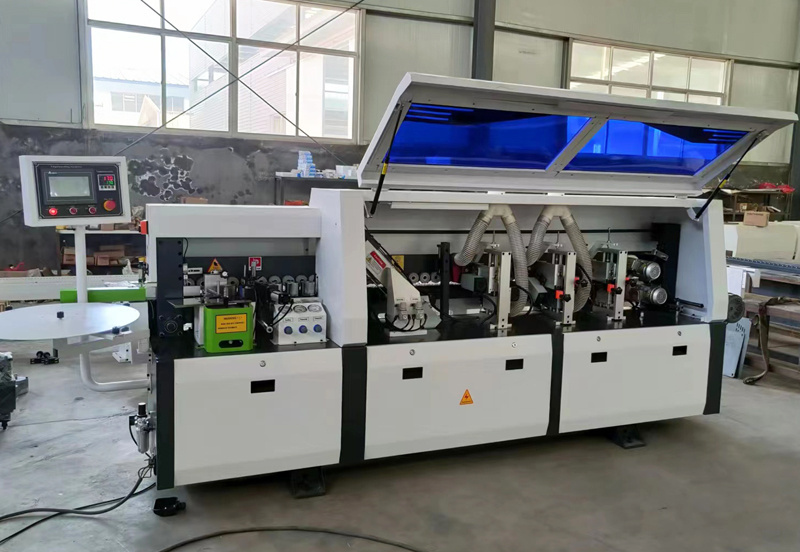

Full Automatic Edge Banding machine

-

Application:

-

Plywood Veneer Production

-

Panel Width:

-

Min80mm

-

Edge Thickness:

-

0.4-3mm

-

Color:

-

Customsied

-

Control system:

-

Detla

-

Material:

-

Sheet Metal

-

Total Power:

-

10kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

4500*900*1500mm

-

Power (kW):

-

10

-

Weight (KG):

-

1100 kg

-

Panel Feed Speed(m/min):

-

15m/min

-

Name:

-

Full Automatic Edge Banding machine

-

Application:

-

Plywood Veneer Production

-

Panel Width:

-

Min80mm

-

Edge Thickness:

-

0.4-3mm

-

Color:

-

Customsied

-

Control system:

-

Detla

-

Material:

-

Sheet Metal

-

Total Power:

-

10kw

Product Description

The automatic linear edge banding machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc.

|

Model

|

GD-2400

|

|

Panel Feed Speed(m/min)

|

15m/min

|

|

Edge Thickness

|

0.4-3mm

|

|

Edge Width

|

10-50mm

|

|

Edge banding height

|

12-60mm

|

|

Panel thickness

|

8-30mm

|

|

Mini work Panel Width

|

> 80mm

|

|

Mini work Panel Length

|

>120 Mm

|

|

Heating power of plastic box

|

1.5kw

|

|

Plate preheating power

|

0.37KW

|

|

End cutting motor power

|

0.55kw * 2 1200r / min200HZ

|

|

Transmission motor power

|

2.2KW

|

|

Polishing motor power

|

0.18kw*2 1400r / min 300Hz

|

|

Fine trimming motor power

|

0.75kw*2 1800r / min 300Hz

|

|

Total power

|

10kw

|

|

Air pressure

|

0.9MPA

|

|

Machine weight

|

2200KG

|

|

Machine size

|

4500*900*1500mm

|

Detailed Images

-

Preheat gelatinization

Taping

Front and end cutting

The glue pot is heated to melt the solid glue, and the screw structure is adopted to deliver glue, so that the glue can be evenly

applied on the board.

At the same time, the cylinder pressing wheel compresses the edge band and the plate to make the adhesion more firm, and there is no glue mark on the plate cotton.

From the front to the back, it is made by Taiwan Yadeke electromagnetic que, Taiwan Yadeke cylinder, and has a unique function of colliding with the plate. It is cut by a special saw blade to enhance the stability of the end.

-

Rough trimming

Fine trimming

Edge scraping device

The roughing tool is a 15 ° flat tool with 40-50 thread allowance for finishing. The automatic tracking and high-frequency high-speed motor are used to realize fast cutting.

The finishing cutter is R2 oblique cutter, which leaves 5-6 wire margin for edge scraping. It adopts profiling automatic tracking and high-frequency motor to realize fast cutting, and R2 oblique cutter can trim radian.

Profiling scraping is used to eliminate the secondary wave marks caused by the cutting process of non-linear movement of trimming, so as to make the upper and lower parts of the plate more smooth and tidy. At the same time, scraping can also adjust the size of the arc, so that the edge sealing effect is more perfect.

Polishing device

Clean the processed plate with cotton polishing wheel, remove the excess glue stains, and make the edge section more smooth and tidy by polishing.

Function can be added

Pre-milling

Pre milling is a customized function: in the first process when the plate enters the conveyor belt, double milling cutters are used to trim the edge collapse, ripple and burr caused by the cutting saw / cutting saw again, so as to achieve better edge sealing effect.

Profiling tracking

Profiling tracking is a custom function: it can repair fillets up and down, and round the four corners, making the end face of the plate more smooth and beautiful. The shape tracking device should be fast reaction and synchronous tracking, which has high requirements for mechanical appliances.

application

Company Introduction

Jinan Grandio CNC Equipment Co., Ltd is an innovative enterprise engaged in research and development,production,sales and good after-sales service.The company's main products include Panel board furniture production line and cabinet door production line:Standard CNC router(For wood,stone,metal..3 axis,4 axis and 5 axis support customized,OEM...)ATC CNC Nesting router,Multi-spindle cnc router machine 3D scanner,Vacuum membrane press machine,Wood sanding machine ,

Automatic edge banding machine,CNC side hole drilling machine Wood CNC lathe ,Fiber laser cutting machine,etc.

Jinan Grandio CNC has16 years of production experience, 11 years of export experience, can provide hands-on technical support, has an independent research and development team, can provide continuous product and software upgrade and update services.Qualified after-sales technical teams in many countries, which can help customers solve after-sales problems locally.Even can help customers who with zero import experience to provide customs clearance to door

service.

Accept customized and OEM production, with 4 main production workshops, cnc router engraving machines, fiber laser cutting machines, other woodworking machinery, like sanding machine and pvc banding machine...Our new workshop is for 3d scanners,like laser scanner,3d Shining scanner, we provide the highest quality products, low prices and the best service, one-stop shopping, for all customers Free agent purchasing servicealways looking for powerful agent, work together, win-win.

FAQ

1. This is the first time I buy the machine, is it easy to operate?

A: We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer" online, with telephone or Skype explain.

2. ARE YOU TRADING COMPANY OR MANUFACTURER ?

A: We are factory.

3. Can I visit your factory?

A: Yes! We greatly welcome customers to visit our factory!

4. What is your MOQ?

A: Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

Hot Searches