Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

weier

-

Voltage:

-

380v,3p,50hz

-

Dimension(L*W*H):

-

22*3.0*3.0 (m)

-

Power (kW):

-

37

-

Weight:

-

10 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

PP/PE + wood powder + additives

-

type:

-

wpc decking profile machine

-

Capacity:

-

30---150kg/h

-

Extruder Type:

-

conical double screw

-

service:

-

life long

-

frequency converter:

-

TECO from Taiwan

-

indicator,button:

-

France TE

-

intelligent temperature controller:

-

omron from Japan

-

Automatic Grade:

-

automatic

-

Marketing Type:

-

Hot Product 2020

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132

-

Screw Speed (rpm):

-

1000 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

weier

-

Voltage:

-

380v,3p,50hz

-

Dimension(L*W*H):

-

22*3.0*3.0 (m)

-

Power (kW):

-

37

-

Weight:

-

10 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

PP/PE + wood powder + additives

-

type:

-

wpc decking profile machine

-

Capacity:

-

30---150kg/h

-

Extruder Type:

-

conical double screw

-

service:

-

life long

-

frequency converter:

-

TECO from Taiwan

-

indicator,button:

-

France TE

-

intelligent temperature controller:

-

omron from Japan

-

Automatic Grade:

-

automatic

-

Marketing Type:

-

Hot Product 2020

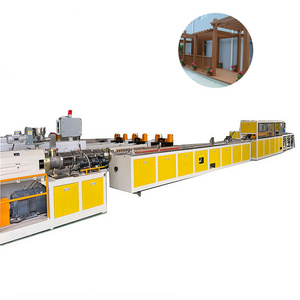

WPC wood PP PE decking profile wood plastic composite board production line machine

WPC decking profile wood plastic composite board production line machine

our wpc wood plastic composite profile extrusion machine, compounding domestic and abroad technology, with characters of high automatic level, steady performance, large output and high efficiency. it is most professional for producing various kinds of wpc profiles both outdoor and indoor by changing different moulds---- that means in same extrusion machine line, you can produce different wpc profiles by just changing different moulds!

2. Production process for PE wpc decking profiles:

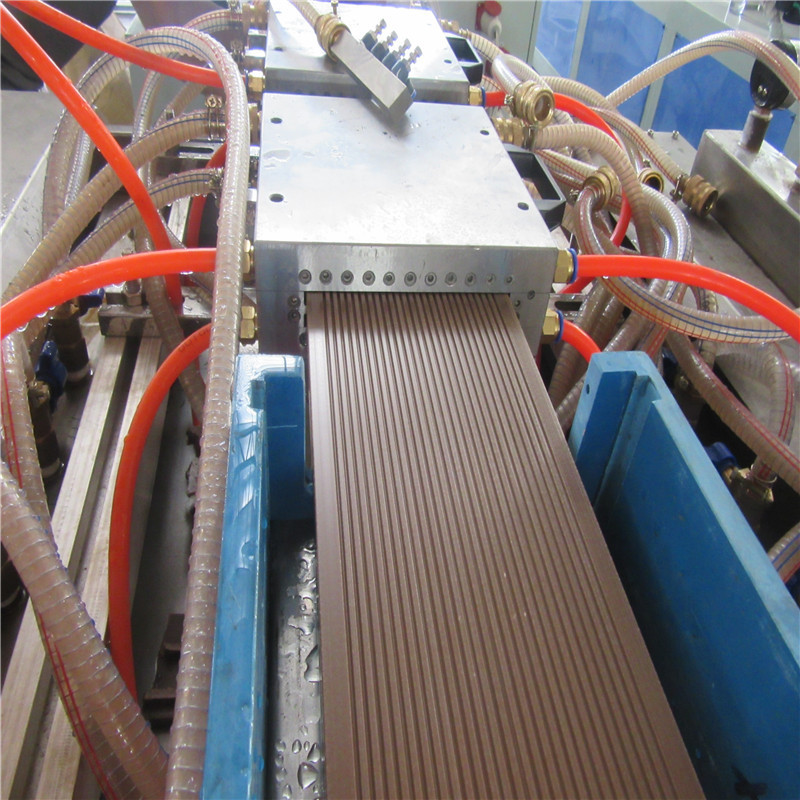

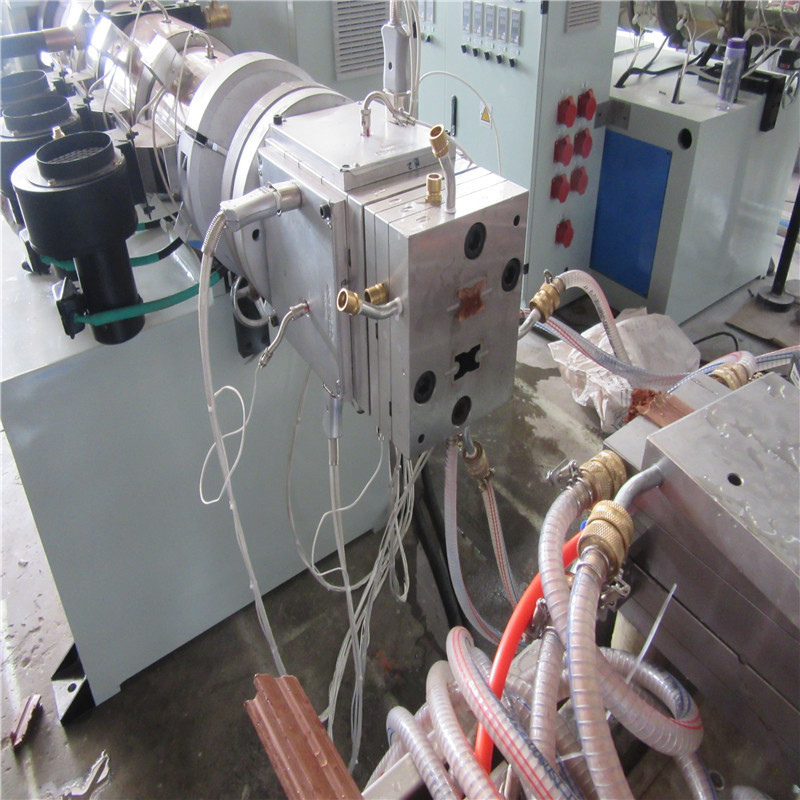

PP/PE powder+wood powder+additives, color pigment → mixing → granulation → extrusion line ( double-screw extruder → ecological wpc profile extrusion die → profile moulds→ vacuum calibration platform →haul-off → cutter →stacker → finished product) → surface finish processing ( sanding, embossing,etc)

3. Equipment list

3.1 Extruder

3.2 Extrusion die

3.3 Profile moulds

3.4 Vacuum Calibrating Table

3.5 haul-off machine

3.6 Cutting machine

3.7 Tilting table

3.8 Electrical control cabinet

Mixing system for WPC Profile Extrusion Line

wpc profile extrusion lines in our factory in qingdao, welcome to visit the wpc production lines running!

Italy customer check our wpc decking profile extrusion line for also fence, post, railing,etc

Chinaplast running our PE WPC decking profile extrusion machine line: W3 F41

4.Composition of wpc profiles production line

(1) conical twin screw extruder

(2) die and mould for wpc profiles

(3) vacuum sizing cooling table

(4) haul off and cutter

(5) reversal stacker

wpc profile samples in our wpc production center in qingdao city

Products you may like

PVC window profile machine pvc edge banding machine pvc roofing sheet machine