- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Progressive stamping die

-

Material:

-

Customized

-

Process:

-

Stamping

-

Surface treatment:

-

Custom Finishing

-

Product name:

-

Custom Sheet Metal Stamping Parts

-

Application:

-

Used Widely

-

Service:

-

Customize ODM OEM

-

Size:

-

Customer's Requst

-

MOQ:

-

1000pcs

-

Type:

-

Hardware Parts

-

Certificate:

-

ISO9001:2015

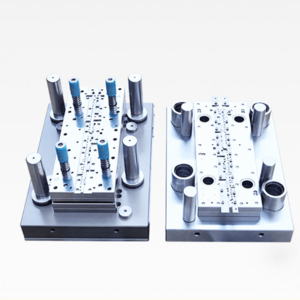

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FCE

-

Model Number:

-

Progressive stamping die

-

Material:

-

Customized

-

Process:

-

Stamping

-

Surface treatment:

-

Custom Finishing

-

Product name:

-

Custom Sheet Metal Stamping Parts

-

Application:

-

Used Widely

-

Service:

-

Customize ODM OEM

-

Size:

-

Customer's Requst

-

MOQ:

-

1000pcs

-

Type:

-

Hardware Parts

-

Certificate:

-

ISO9001:2015

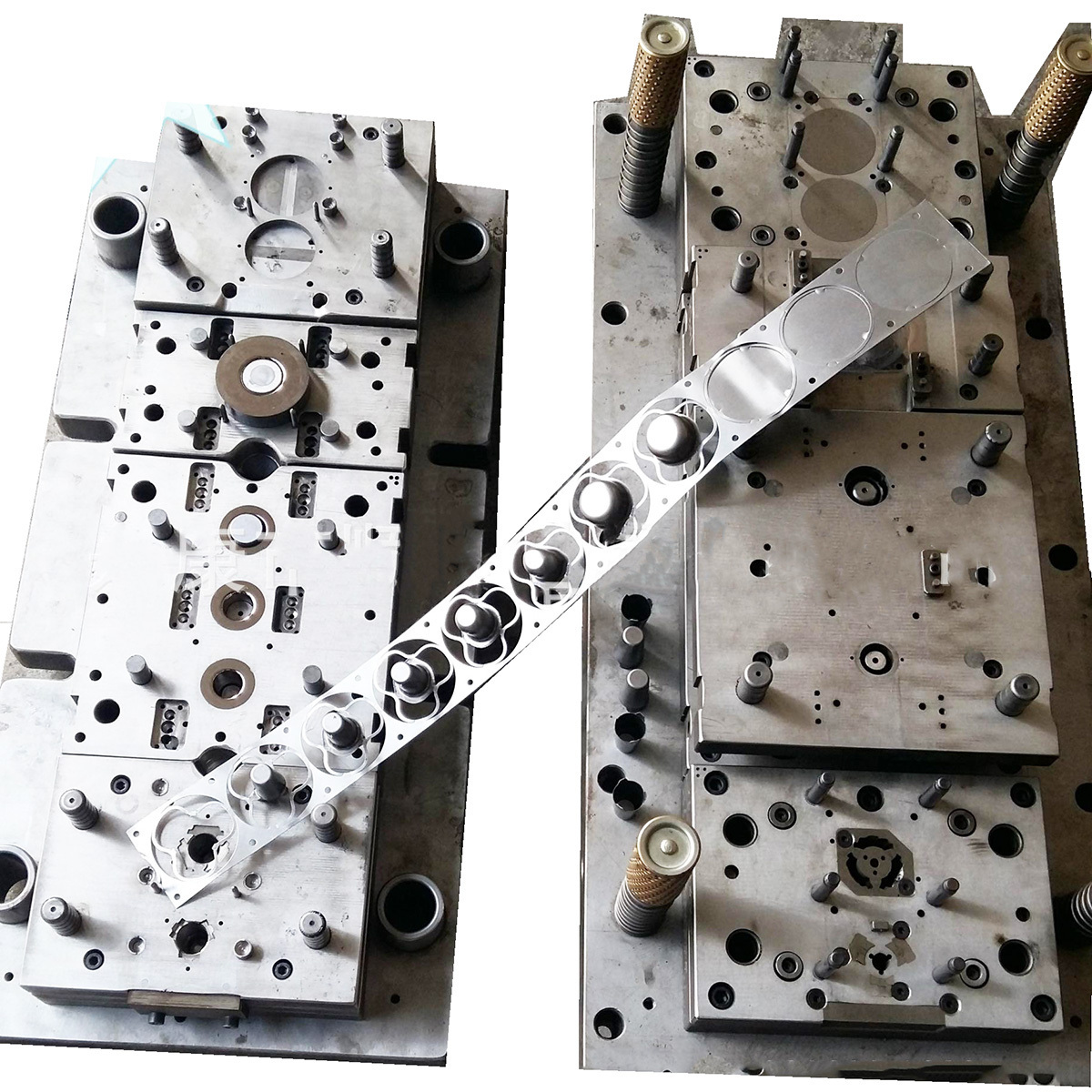

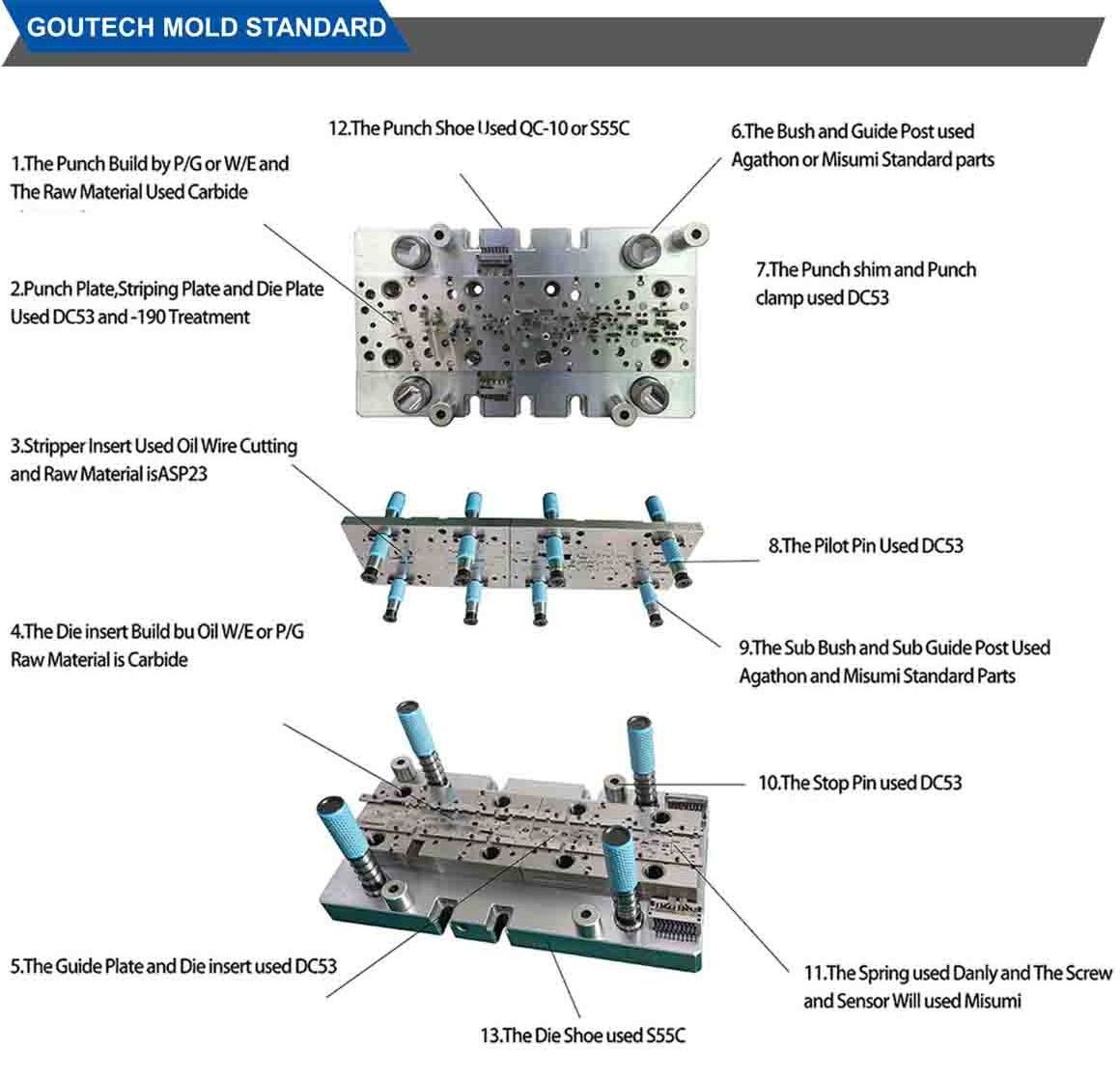

Metal Progressive Draw Sheet Forming Stamping Blanking Dies

| COMPANY NAME | Suzhou GouTech Precision Technology Co.,Ltd |

| BUSINESS TYPE | Manufacturer |

| MAIN PRODUCTS | Metal Stamping Die, Stamping Processing, Plastic Injection Mold, Prototype tool, Injection Molding Parts, for Auto, Consumer Electronics, Appliance, Medical, Houseware… |

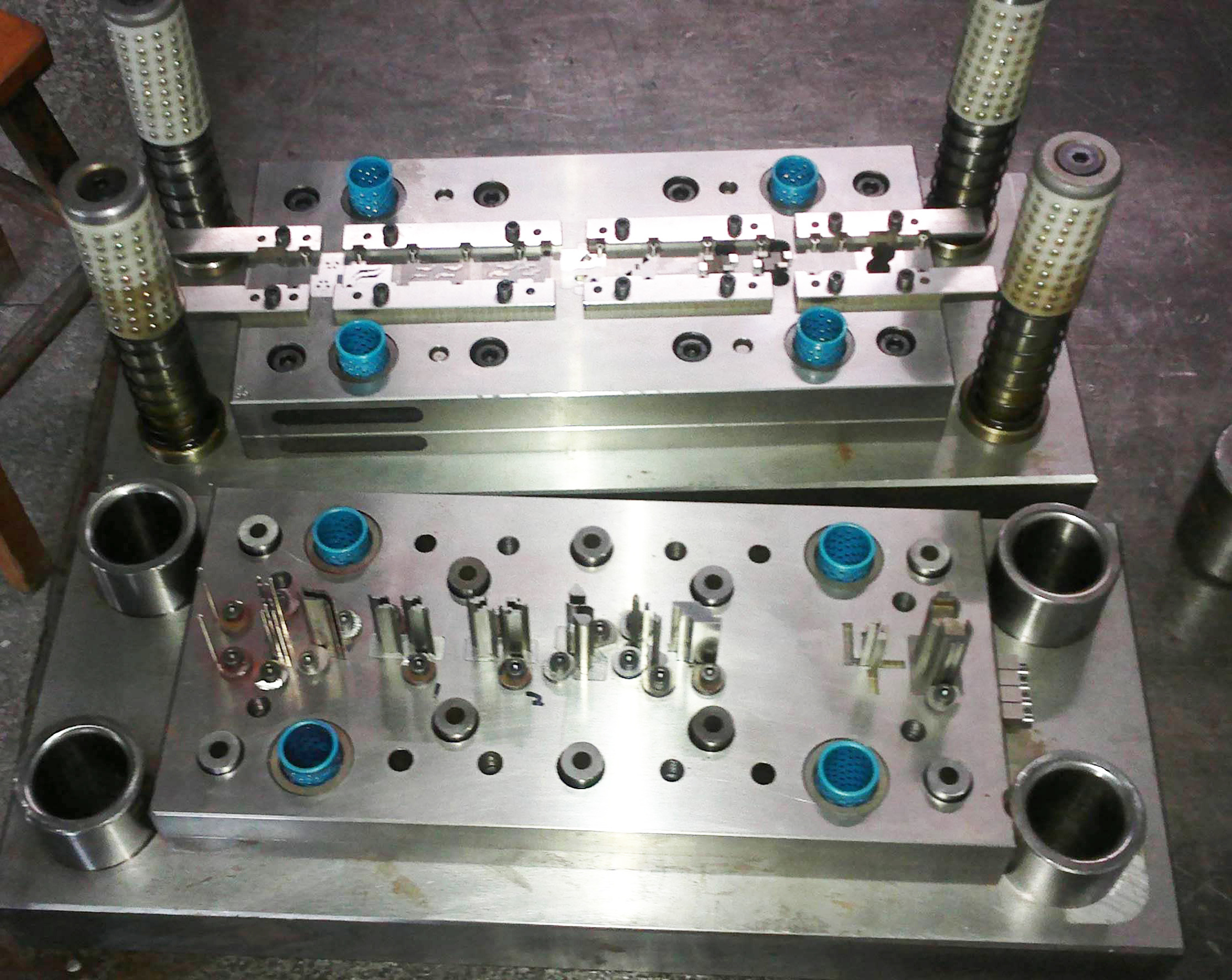

| MOULD BASE | DME, SD, LKM, HASCO or Goutech Standard for specific parts |

| MOLD MATERIAL |

SKD11,QC-10,DC53,S55C,asp23, HIGH SPEED STEEL... |

| MOLD ACCURACY | +/-0.003mm |

| MOLD LIFE | 50K-1Million Shots |

| CAVITATION | Single cavity, multi-cavity |

| MOLD MANUFACTURE EQUIPEMENT | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

| MOLDING FACILITY | 35 TO 650ton Horizontal injection machines, 50 to 160ton Vertical injection machines |

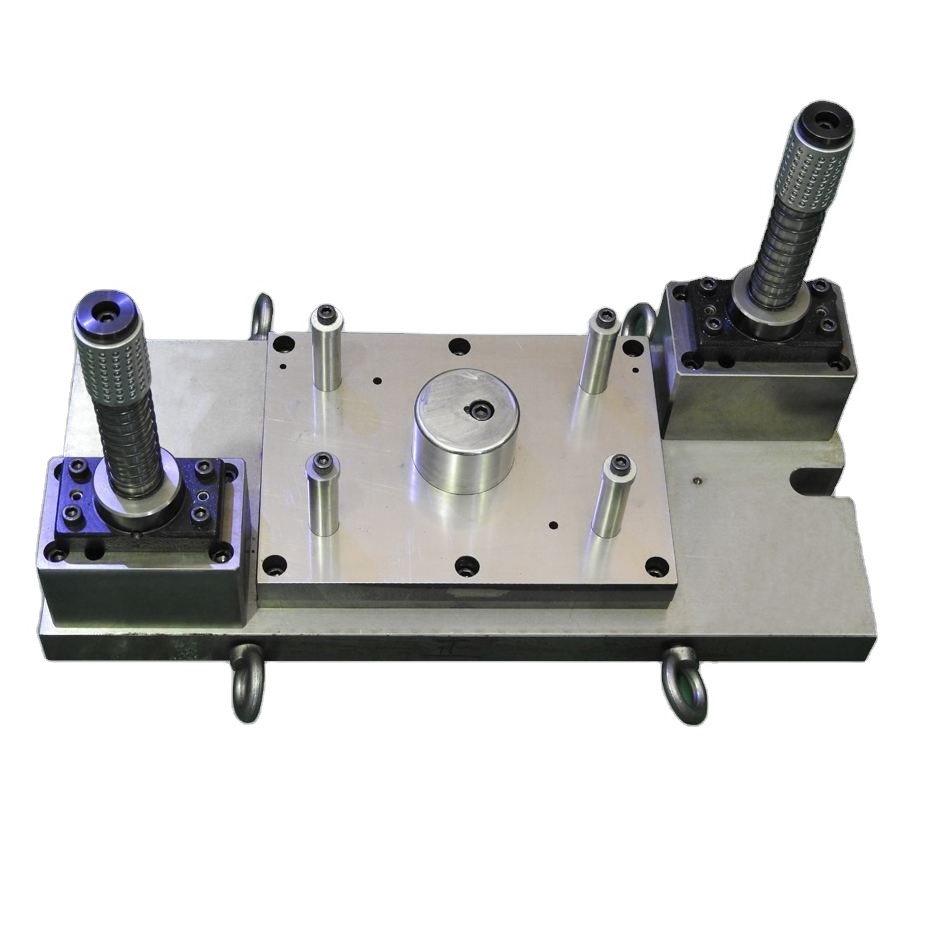

| STAMPING MATERIAL | Stainless steel, Aluminum, brass metal sheet |

| SURFACE TREATMETN | Vabriator de-burr, Polishing, Anodizing, Coating, Laser mark |

| CERTIFICATES | ISO 9001, IATF16949 |

| QAULITY POLICY | Customer-centric, Action concurrent with words |

| Projects | Advantages | Benefit |

| Product | Long Life Mold | Up to 150million shots, one mold meet whole life cycle |

| Stable Quality | High PPK value, wide process window, low machine requirement | |

| High Efficiency | Save you production cost | |

| High Precision | B etter fitting for second process, higher yield | |

| Easy Maintenance | Increase output, reduce down time | |

| Service | One-stop solution | Save your time, professional service |

| Product innovation | Add value onto your product | |

| Design for X | Multi dimensions optimization | |

| Free spare part, free technical support | One time buying forever serving | |

| Solution of Painpoints | Safe Transaction | Protected transaction/schedule/Quality |

| Quick Setup Production | Load the Mold >> key in process we recommend >> start production, make the work simple | |

| Full Evidence | Load Mold >> key in process we recommend >> start production, make the work simple | |

| Free Running-in Issue | Running-in in house, issue solved in Goutech |

Q1. Are you a trading company or factory?

Factory, Gou Tech was founded in 2005, own Injection Mold, Molding, Stamping, Machining & Assembly workshops within 500m. Welcome to Visit

Q2.How can I get a Quotation?

1)

3D with

stp

.(

preferred)

igs

,

st.

prt

. format

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and a Year)

We can help you complete above for ODM project

Q3

.How do you ensure product quality?

As you can see above, we apply assessment, planning, monitor at every single process. Some

bullet points:

Q4.

How do you ensure on time delivery?

1) Detailed planning, details to per hour/person/machine number/stakeholder…

2) Main material driving management system

3) Daily progress meeting, a recovery plan will be reviewed by management team once any key chain is delay.

4) If delay happen on delivery, Goutech will provide customer 1% discount for one week delay, up limit to 10%

Q5.

What is your defective part handling process

Goutech

have good traceability record for people/machine/parameter/material batch/inspection, that will help quick quarantine defect parts, find out root cause and apply prevention method

Q6. What's the payment term?

Normally

50

% pay in advance, balance the rest against to the shipment B/

L.