- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ATM-Cr

-

Shape:

-

Tube

-

Material:

-

Chromium

-

Purity:

-

3N5 (99.95%)

-

Size:

-

ID79,OD89.6,L504, or OEM

-

Thickness:

-

10mm or OEM

-

Density:

-

7.12g/cm3 (99%)

-

Produce method:

-

HIP

-

Grain size:

-

≤200um

-

Packing:

-

Vacuum packing

-

Outside packing:

-

Non fumigation wooden carton

-

Certificate:

-

ISO9001,COA,MSDS

Quick Details

-

Application:

-

PVD sputtering materials, Surface Coating

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ATM

-

Model Number:

-

ATM-Cr

-

Shape:

-

Tube

-

Material:

-

Chromium

-

Purity:

-

3N5 (99.95%)

-

Size:

-

ID79,OD89.6,L504, or OEM

-

Thickness:

-

10mm or OEM

-

Density:

-

7.12g/cm3 (99%)

-

Produce method:

-

HIP

-

Grain size:

-

≤200um

-

Packing:

-

Vacuum packing

-

Outside packing:

-

Non fumigation wooden carton

-

Certificate:

-

ISO9001,COA,MSDS

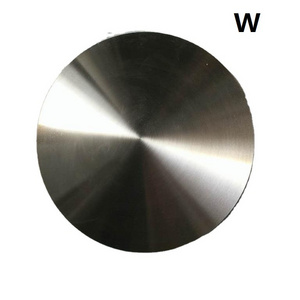

Product Description

Rotary tube 3N5 purity chromium target

Size:

ID79,OD89.6,L504

with 12mm thickness (or any size you want)

Popular standard size or OEM machining

Produce method: HIP

Popular standard size or OEM machining

Produce method: HIP

|

Item No.:

|

Chemical composition

|

|

Cr (wt%)

|

≥99.95%

|

|

Fe

|

≤50 ppm

|

|

Al

|

≤50 ppm

|

|

Si

|

≤50 ppm

|

|

C

|

≤50 ppm

|

|

N

|

≤50 ppm

|

|

O

|

≤100ppm

|

|

S

|

≤50 ppm

|

Smooth edge

Well machined with smmoth edge.

Laser marking

Laser marking to track the all process during producing.

Clear thread

All thread are clear and precise.

(1) Smooth surface without pore,scratch and other imperfection

(2) Grinding or lathing edge, no cutting marks

(3) Unbeatable lerel of material purity

(4) High ductility

(5) Homogeneous micro trucalture

(6) Laser marking for your special Item with name, brand, purity size and so on

(7)

Every pcs of sputtering targets from the powder materials item&number, mixing workers,outgas and HIP time,machining person and packing details are all made ourselves.

All of those step can promise you once a new sputtering target or method is created ,it could be copied and kept to support a stabel quality products.

-

-

Other dvantage:

high quality materials

(1) 99 % density = 7.12 g/cm³

(2)Dimensional stability

(3)Enhanced mechanical properties

(4)Uniform grain size distribution

(5)Small grain sizes

(1) 99 % density = 7.12 g/cm³

(2)Dimensional stability

(3)Enhanced mechanical properties

(4)Uniform grain size distribution

(5)Small grain sizes

Popular usage

(1) In cutting tools coating, Such as cutting and drawing tools, various materials of pressing mold and mold, bearing, shaft,

gauge, gear, etc

(2)Protection and decoration of automobile, bicycle, sewing machine, clock, instrument, daily hardware and other parts

(3)Storage of lubricating media, prevent non lubrication operation, improve the anti friction and wear resistance of workpiece surface. It is often used to coat the surface of sliding friction parts under heavy pressure, such as internal combustion engine cylinder bore, piston ring, etc

(4)It has uniform luster, good decoration and good extinction:

Protection and decoration of parts and components of aviation instrument and optical instrument, solar absorption panel and daily necessities

Detailed Images

High density

Uniform and fine grained micro structure

Homogeneous concerning distribution of chemical elements

Low content of residual impurities

Uniform and fine grained micro structure

Homogeneous concerning distribution of chemical elements

Low content of residual impurities

Size Information

Packing&Shipping

vacuum packing

Every pcs of the all targets will be in

vacuum packing septartely first to avoid

oxidation,contaminated,contact touch and so on.

Non fumigation wooden box packing outside

Vacuum packing sputter will be packed in cartons with

fixed support

Certification

(1) All Advanced targets are produced under ISO9001 quality control.

With Marks or lables on packing or products ,so we can track the all producing type and person.

(2)

Every pcs of sputtering targets from the powder materials item&number, mixing workers,outgas and HIP time,machining person and packing details are all made ourselves. All of those step can promise you once a new sputtering target or method is created ,it could be copied and kept to support a stabel quality products.

(3) With MSDS and COA test report for every single order.

After Sales Service

Laser marking

1. We can help

Laser marking on every pcs of the sputter targets.

Mark can be with your logo and item ,purity,size and so on.

2.With the

Laser marking, we can help check,track the every pcs target the all producing process. Like how it mixed ,HIP time ,who maching and clean it ,who pack it .

3.If there is some quality problem ,just need to show us the marks ,so we can find what happened in each process and find out how to deal with it to avoid next time.

4.Free to return, reback quality products and free to make a new one immediately.

Company Introduction

Advanced Targets Materials Co., Ltd

is one of the leading manufacturers of sputtering targets, arcing cathodes and evaporation materials for the PVD thin film companies worldwide. Advanced Targets has rich experience in manufacturing and R&D on sputtering targets and arcing cathodes. Driven by the spirit of innovation, Advanced Targets achieved lots of R&D progress, and some are worked together with Institute of Process Engineering Chinese Academy of Sciences, national center for Non-Ferrous Metals & Electronic Materials.

Advanced Targets’s products have been serving for the leading PVD service suppliers around the world. Consistent high quality and cost efficiency are the key advantages of Advanced Targets. Relying on material science and material processing know-how, Advanced Targets has won a good reputation worldwide.

Driven by the mission of “Innovation, Sincerity, Quality”, Advanced Targets has been supplying a wide range of high-qualitysputtering targets and arcing cathodes recognized by many well-known companies in PVD thin film field.

Advanced Targets’s products have been serving for the leading PVD service suppliers around the world. Consistent high quality and cost efficiency are the key advantages of Advanced Targets. Relying on material science and material processing know-how, Advanced Targets has won a good reputation worldwide.

Driven by the mission of “Innovation, Sincerity, Quality”, Advanced Targets has been supplying a wide range of high-qualitysputtering targets and arcing cathodes recognized by many well-known companies in PVD thin film field.

FAQ

1. Are you trading company or manufacturer ?

Advanced Targets: We are a professional manufacturer of PVD targets, powder metallurgical/Melting/plasma spray are the main process we focused on.

2.What is HIP process:

HIP is a short name of Hot isostatic Pressing. This technology is forming process combining simultaneous heating and pressing to consolidate powders in high temperature, high pressure as well as under argon(Ar) atmosphere, primarily used to eliminate voids and defects in materials. HIP is mainly applied to a wide range of Materials, it is the best fabrication methods for Cr targets and powder metallurgy aluminum alloy targets.

3. Do you have some experience if supplying hardcoating materials?

Advanced Targets: We have been keep supplying many kinds of targets servicing for Eifeler/Balzers/ Hauzer/Platit/Kobelco/isys and other coating systems. They are satisfied by our good service and stable products quality.

4: How long is your delivery time?

Advanced Targets: 15 days after order date for those regular size or samples, Normally 30 days for batch quantity.

5. Do you have quality control system:

Advanced Targets: Yes, we have been ISO 9001 qualified since 2015.And our quality control system have been mutual accepted by IQNET(International Certification Network).

6: Do you have Minimum order quantity requirement?

Advanced Targets: For common products, we donot have MOQ requirement. For R&D products, we can supply sample.

7: What is your payment method?

Advanced Targets: T/T in advance, Paypal , Western Union and etc.

Hot Searches