- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220v or 380v

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Paixie

-

Dimension(L*W*H):

-

1200*800*2000

-

Weight:

-

550 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic grade:

-

fully automatic

-

Filling capacity:

-

100-5000ml or customzed

-

Certificate:

-

CE, ISO9001

-

Machine material:

-

stainless steel

-

Sealing rate:

-

≥99%

-

Guarantee:

-

one year free

-

Certification:

-

CE, ISO9001

-

Marketing Type:

-

New Product 2022

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Glass, Metal, Plastic, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

99%

-

Voltage:

-

220v or 380v

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Paixie

-

Dimension(L*W*H):

-

1200*800*2000

-

Weight:

-

550 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic grade:

-

fully automatic

-

Filling capacity:

-

100-5000ml or customzed

-

Certificate:

-

CE, ISO9001

-

Machine material:

-

stainless steel

-

Sealing rate:

-

≥99%

-

Guarantee:

-

one year free

-

Certification:

-

CE, ISO9001

-

Marketing Type:

-

New Product 2022

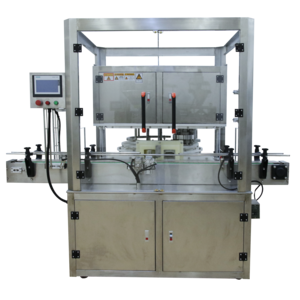

high speed easy opening lid tin can making equipment in china

The tin can filling machine can finish measurement, filling and so on. Because its unique design, it is more applicable to pack those powders and granules which is free-flowing or with less liquidity, coffee, particle material additive, white granulated sugar, soft white sugar, glucose, monsodium glutamate, solid drink,solid medicine, carbon dust, talcum powder, pesticide, dye, flavors and fragances and so on. The whole line of tin can filling machine is consists of unscramble bottle machine, filling machine, sealing, labeling machine etc.

Features:

1. The tin can filling machine can finish the bottle unit, filling and measurement for automatic orientation work.

2.The tin can filling machine adopts servo, PLC and touch screen control, so it's easy operate and high stability.

3.It is well laid-out, easy to take apart and wash.No tools are needed to install or strip the machine.

4. The machine packing machine is designed according to GMP requirements, which is made of stainless steel completely under the internation of SUS316L, SUS304.

5. The spirial is controlled by high-speed reacting clutch brake which is of high accuracy, high speed, high torque and long operating life and etc.

6. The tin can filling machine will alarm or stop workiing automatically if unconventional problems happen(such as counting mistake, miss bottles)

Main technical parameters

|

Name

|

tin can filling machine |

| Production capacity | 1000-6000 bottles/h |

| Bottle size | 100-1000ml can be customized |

| Package accuracy | ±1% |

| Sealing rate | ≥99% |

|

Filling material

|

powder, granular powder

|

| Hopper capacity | 35-40 liters |

|

Filling head |

1/2/4/6/8 can be customized |

|

Material |

stainless steel of 316L |

|

Machine weight

|

550kg

|

pictures of tin can sealing mahcine

samples

filling

filling nozzles

sealing

filling sealing

Touch screen

Certification

Our customer:

1. Warranty time: All machines are guaranteed for one year free that we provide spare components except the wrong operation or damaged by people on purpose.

2.Teaching services: Our engineers will teach your staff to operate the machine during the period of installation and commissioning, and they will not leave until your staff can operate it properly and normally when it necessary.

3.Certificate services: Complying with our clients’ request, we can provide related certificates to clients freely

4. Maintenance services: If you have any questions or any malfunction happened, we will reply you within 48 hours except the special reasons once you enquiry us, you also can call our helpline Offering:0086-21-34781699

The machines can be customized according to your requirements.