- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Acrylic, Acrylic

-

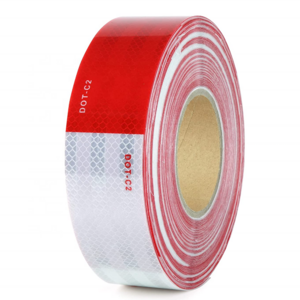

Color:

-

Red+White

-

Size:

-

6'' White * 6'' Red

-

Certification:

-

FMVSS 108 ASTM D4956

-

Grade:

-

Diamond Bright Grade

-

Technology:

-

Metalized Microprism Technology

-

Durability:

-

8+ Years Durability

-

Reflective Brightness:

-

400+ CPL (cd/lumix/m2)

-

Feature:

-

Weather Resistant

-

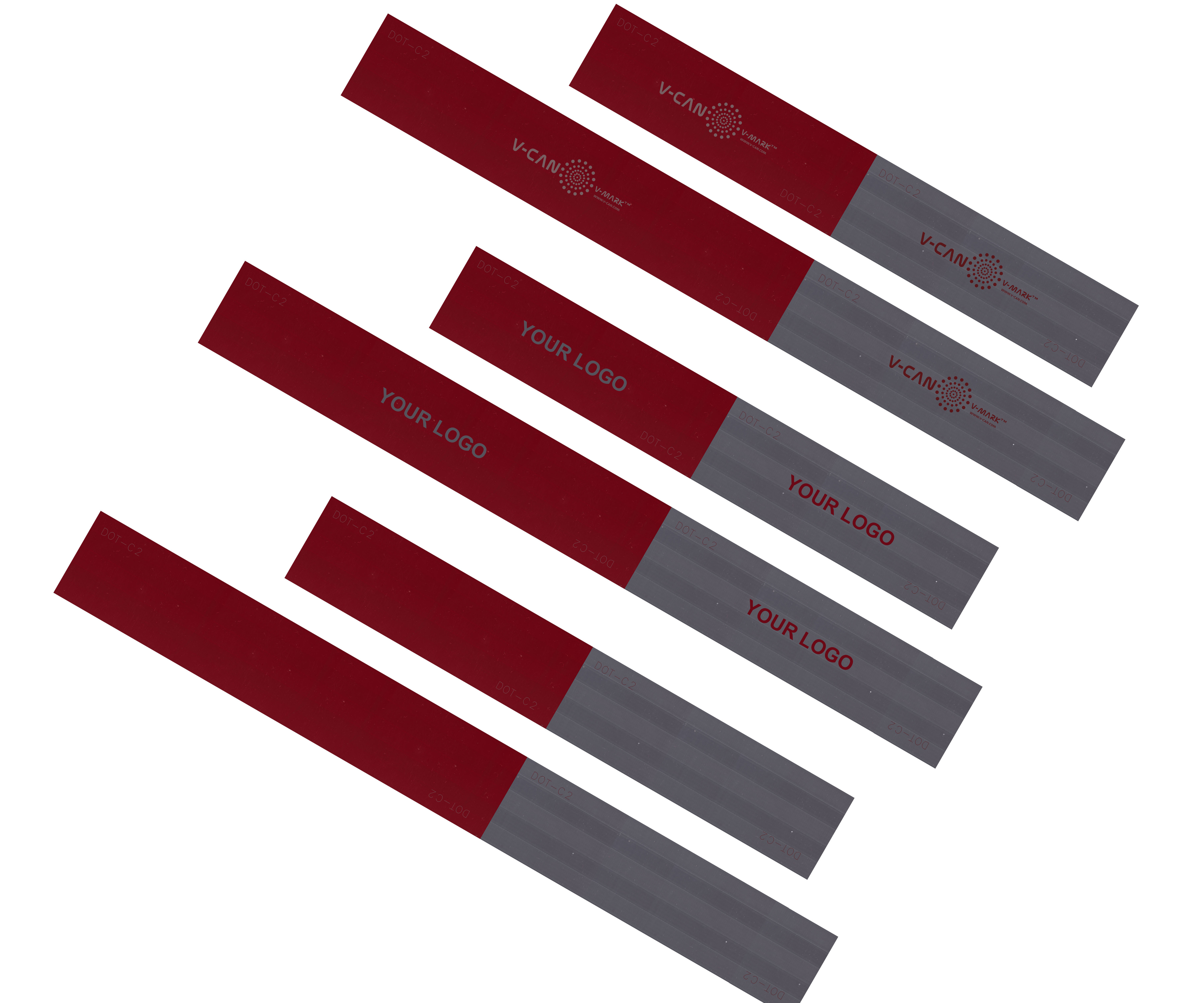

Logo:

-

DOT-C2(Customizable)

Quick Details

-

Place of Origin:

-

China

-

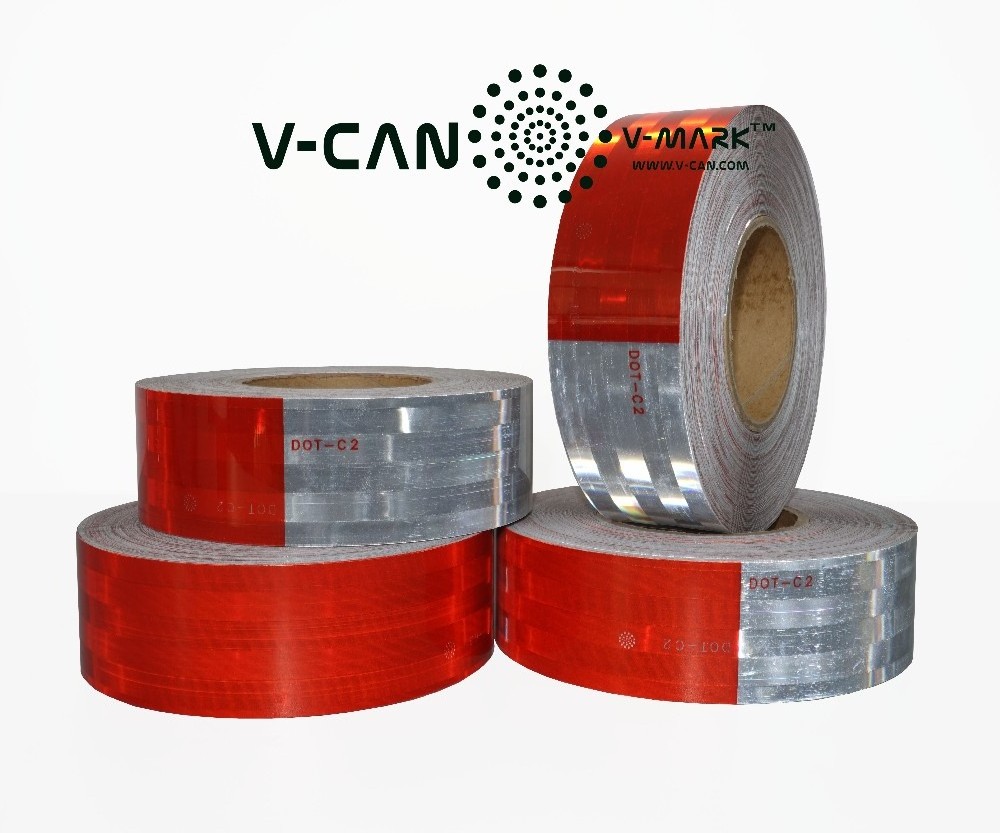

Brand Name:

-

V-MARK

-

Type:

-

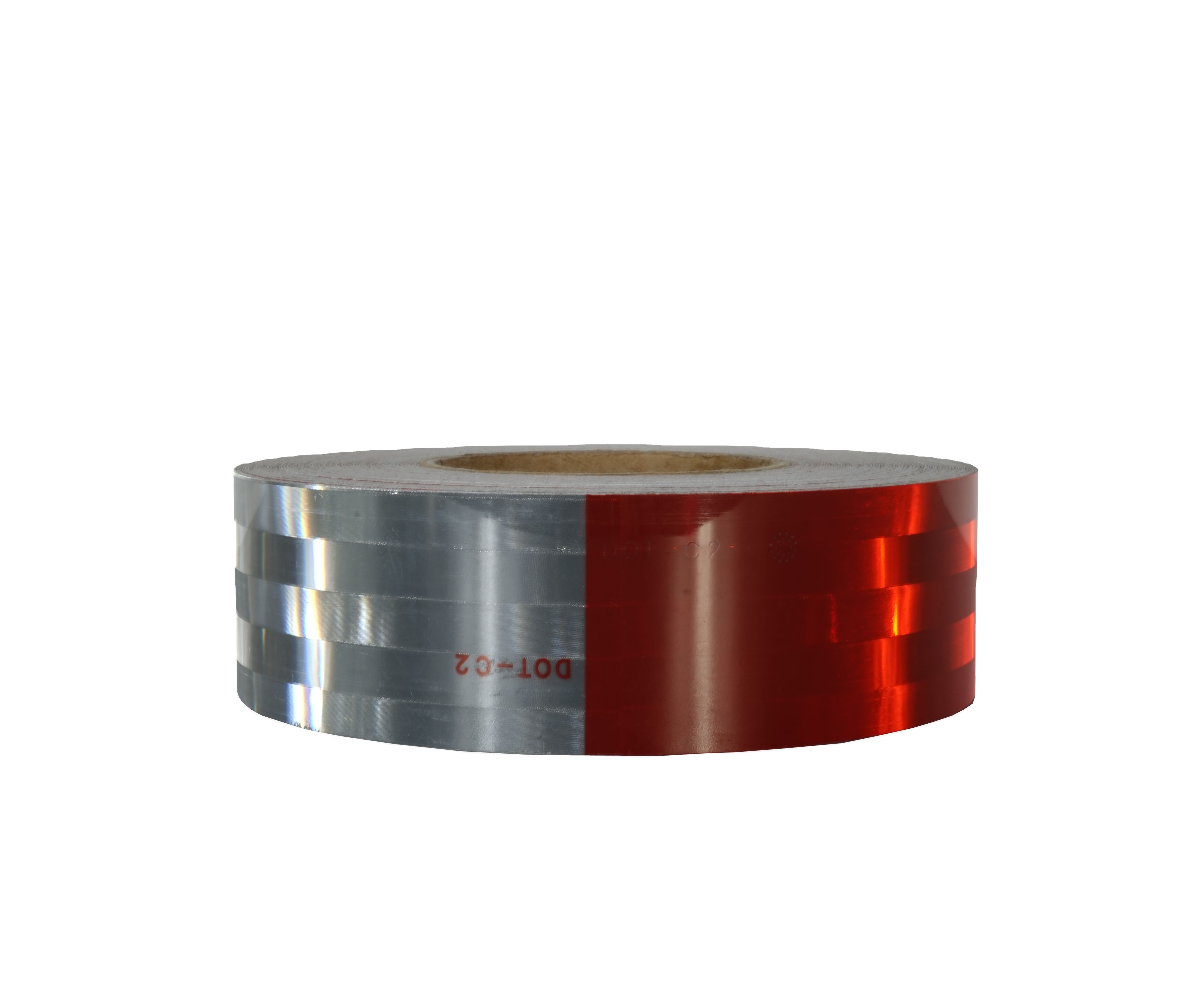

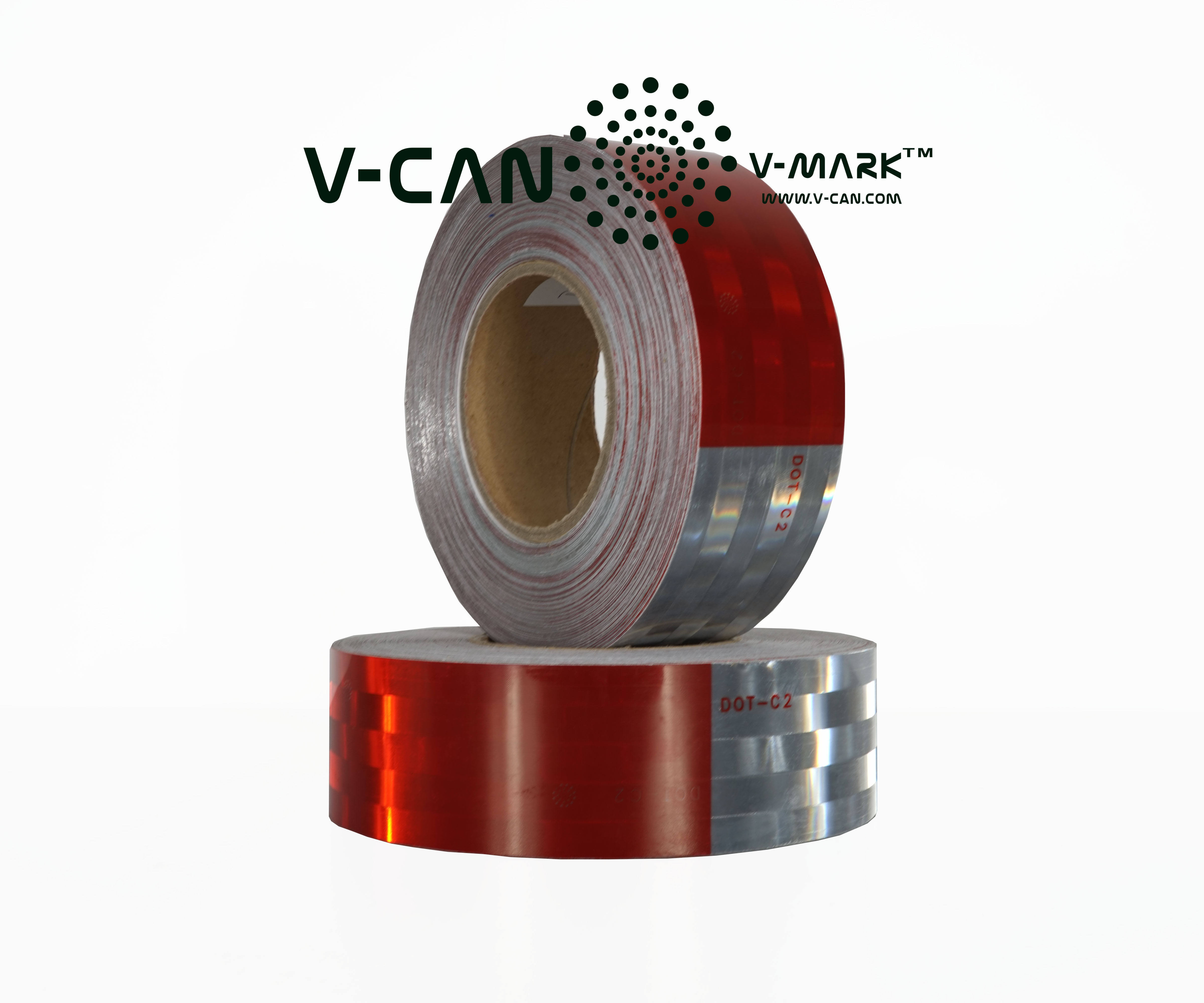

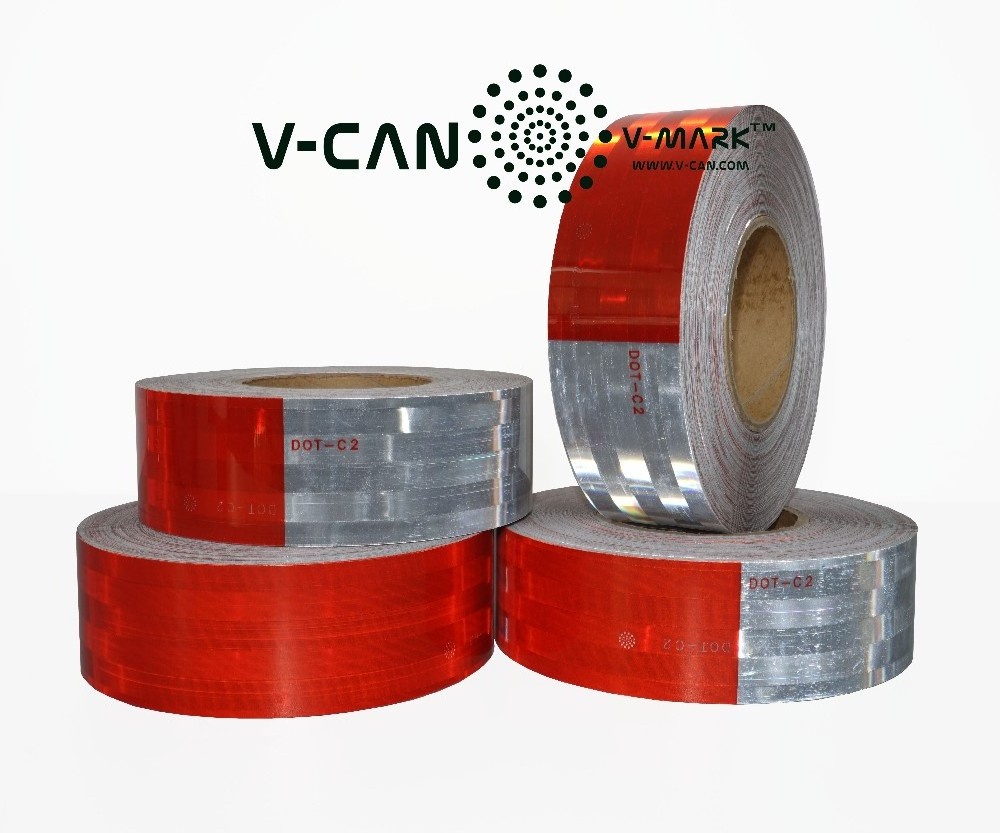

Conspicuity Reflective Safety Tape

-

Material:

-

Acrylic, Acrylic

-

Color:

-

Red+White

-

Size:

-

6'' White * 6'' Red

-

Certification:

-

FMVSS 108 ASTM D4956

-

Grade:

-

Diamond Bright Grade

-

Technology:

-

Metalized Microprism Technology

-

Durability:

-

8+ Years Durability

-

Reflective Brightness:

-

400+ CPL (cd/lumix/m2)

-

Feature:

-

Weather Resistant

-

Logo:

-

DOT-C2(Customizable)

Product Description

V-MARK™ Reflective Material – Vehicle Conspicuity Markings #

DB-DOT-180012

consists of microprismtic lenses that are intergrated in a transparent, smooth surface, tough and weather-resistant synthetic resin, and backed with a pressure sensitive adhesive and paper liner. If they are applied to properly prepared surfaces, Vehicle Conspicuity Markings should provide a long time of field performance.

DB-DOT-180012

can be used on truck, trailers, fleet, oil tanker, farm equipment, automobiles and all types of mobile and industrial equipment.

DB-DOT-180012

are made strictly according to FMVSS 108, ASTM D4956, and similar standards.

Product Code

DB-DOT-180012

DB-DOT

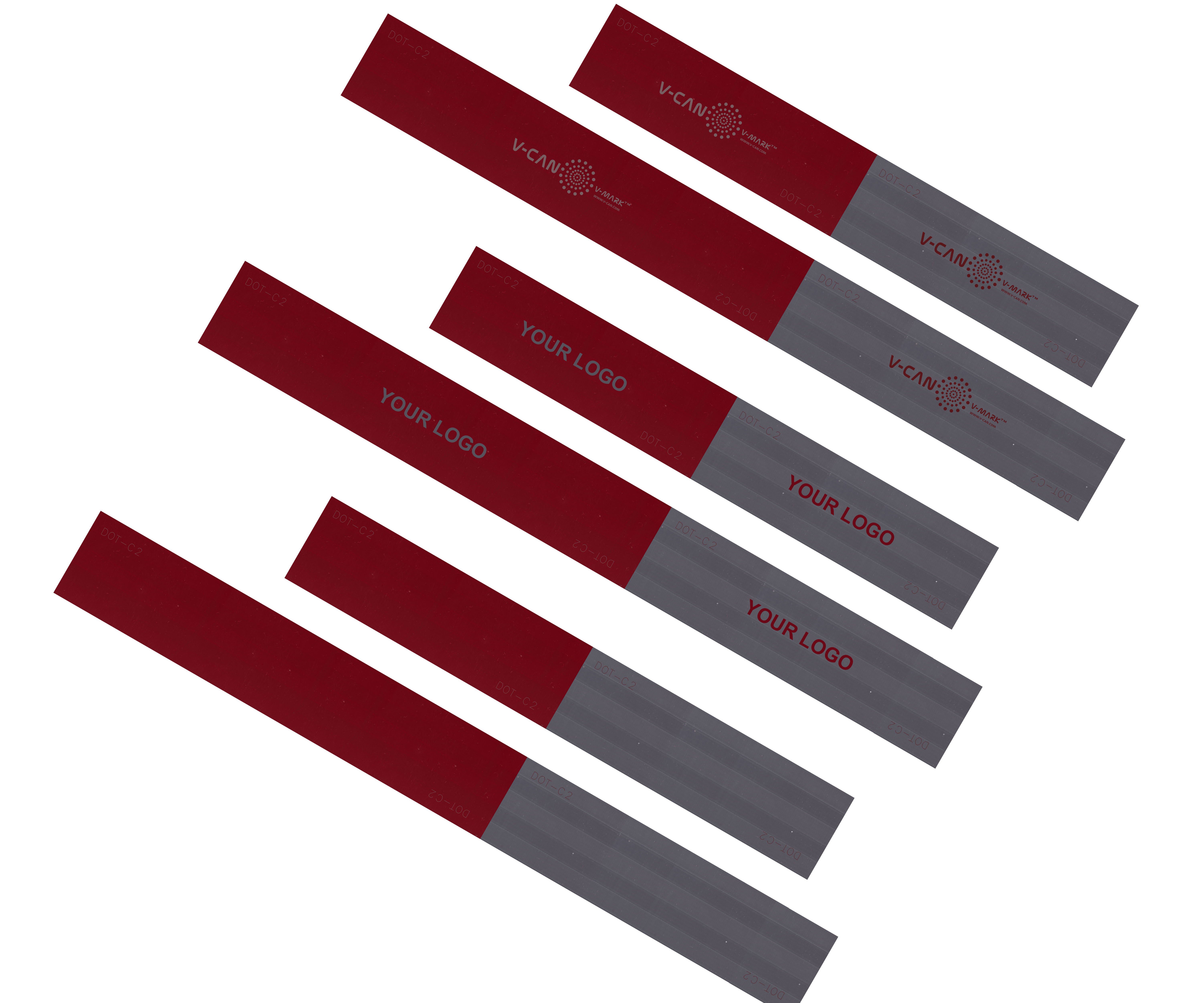

Diamond Bright Grade Retro-Reflective Brightness, DOT-C2 Marking

1800

1800 inch per roll in length (150 sections of 6" White + 6" Red )

12

6" White + 6" Red in Continuous Alternating Pattern

Product Overview

Material

Acrylic

Durability

8+ Years

Color

Red + White color

Reflective Technology

Metalized Microprism Technology

400+ cd/lumix/sqm

Super intensity reflective brightness. 1.5+ times of the retro-reflective values required by standards.

FMVSS 108

Completely conforms to USA Department of Transportation FMVSS 108 and similar standards.

Size

5cm x 45.7m per roll

Application

Truck, trailer, oil tanker, pick-up, farm equipment, industrial equipment and other vehicles

OEM Service

Logo imprinting, Kiss-cutting, Die-cutting, perforating, OEM packaging are acceptable.

Application and Installation Instructions

Tools Required

* Clean cloths

* Craft knife

* Squeegee covered with a clean cloth to avoid scratching the material

* Old vehicles only: Abrasive pad

* Solvent Cleaner: Isopropyl alcohol (IPA)

* Craft knife

* Squeegee covered with a clean cloth to avoid scratching the material

* Old vehicles only: Abrasive pad

* Solvent Cleaner: Isopropyl alcohol (IPA)

V-MARK™ Reflective Material – Vehicle Conspicuity Markings can be applied to new and used trucks and trailers with painted rigid sides, as well as unpainted surfaces e.g.stainless steel

Application temperature

* To ensure proper adhesion between the tape and the cleaned substrate, bonding materials must be applied when both the substrate and tape temperature is between 15° C and 38° C. The temperature needs to be consistent for at least one hour after

application.

* It is recommended that vehicle conspicuity markings are stored at temperatures between 18° C and 28° C.

Where to apply

* Use the guidelines provided in Regulations (such as: ECE 104, DOT FMVSS 108) to ensure that the markings (tapes) are in

general positioned correctly on the vehicle.

* The user is responsible for determining whether the V-MARK™ product is fit for a particular purpose and suitable for the user’s

application.

* Users are urged to carefully evaluate substrates for material adhesion and compatibility.

Listed below are guidelines for selected substrates. Material failures caused by the substrate or improper surface preparations

are not the responsibility of manufacturer or its distributors.

Two-part polyurethane paints

* Two-part polyurethane paints must be cured before applying V-MARK™ markings (tape). If the paint is not properly cured,

outgassing will cause bubbles to form under the applied material and the adhesive will not adhere adequately.

* V-MARK™ recommends testing for outgassing prior to applying vehicle conspicuity markings (tape).

* For drying times, paint manufacturers’ guidelines are to be followed in all instances. While most paints are usually touch-dry

within a few hours, dependent upon the primer, paint mixture and thickness, proper curing may make significantly longer, up to

one week.

GRP (Glass Reinforced Plastics) and/or gelcoated surfaces

* Similar guidelines to the above will apply for composite materials such as GRP substrates and/or gelcoated surfaces, in that

the substrate must be properly and fully cured before applying, otherwise outgassing may result.

Outgassing Plastics

* Polycarbonates, Polyprenes and other plastics can interact with the environment absorbing or outgassing moisture, or outgassing processing aids and solvent carriers for additives, which might cause the formation of bubbles on the film. Preliminary tests are essential to ensure that no adverse effects arise from this interaction.

Stainless Steel

* The same application guidelines and warranty as the standard product apply.

Surface cleaning

* The purpose of cleaning the substrate is to remove any dirt or contamination.

* It is very important that the surface is free of dust and grease, and ideally the surface should be smooth.

* Use a clean cloth with isopropyl alcohol to wipe the surface in one direction only to avoid spreading contamination. With a dry

clean cloth wipe away the cleaner before evaporation.

* Repeat this process until the surface is clean, i.e. when there is no visual dirt or contamination transfer onto the cloth.

Ensure the surface is dry and the isopropyl alcohol has completely evaporated before commencing application.

* To ensure proper adhesion between the tape and the cleaned substrate, bonding materials must be applied when both the substrate and tape temperature is between 15° C and 38° C. The temperature needs to be consistent for at least one hour after

application.

* It is recommended that vehicle conspicuity markings are stored at temperatures between 18° C and 28° C.

Where to apply

* Use the guidelines provided in Regulations (such as: ECE 104, DOT FMVSS 108) to ensure that the markings (tapes) are in

general positioned correctly on the vehicle.

* The user is responsible for determining whether the V-MARK™ product is fit for a particular purpose and suitable for the user’s

application.

* Users are urged to carefully evaluate substrates for material adhesion and compatibility.

Listed below are guidelines for selected substrates. Material failures caused by the substrate or improper surface preparations

are not the responsibility of manufacturer or its distributors.

Two-part polyurethane paints

* Two-part polyurethane paints must be cured before applying V-MARK™ markings (tape). If the paint is not properly cured,

outgassing will cause bubbles to form under the applied material and the adhesive will not adhere adequately.

* V-MARK™ recommends testing for outgassing prior to applying vehicle conspicuity markings (tape).

* For drying times, paint manufacturers’ guidelines are to be followed in all instances. While most paints are usually touch-dry

within a few hours, dependent upon the primer, paint mixture and thickness, proper curing may make significantly longer, up to

one week.

GRP (Glass Reinforced Plastics) and/or gelcoated surfaces

* Similar guidelines to the above will apply for composite materials such as GRP substrates and/or gelcoated surfaces, in that

the substrate must be properly and fully cured before applying, otherwise outgassing may result.

Outgassing Plastics

* Polycarbonates, Polyprenes and other plastics can interact with the environment absorbing or outgassing moisture, or outgassing processing aids and solvent carriers for additives, which might cause the formation of bubbles on the film. Preliminary tests are essential to ensure that no adverse effects arise from this interaction.

Stainless Steel

* The same application guidelines and warranty as the standard product apply.

Surface cleaning

* The purpose of cleaning the substrate is to remove any dirt or contamination.

* It is very important that the surface is free of dust and grease, and ideally the surface should be smooth.

* Use a clean cloth with isopropyl alcohol to wipe the surface in one direction only to avoid spreading contamination. With a dry

clean cloth wipe away the cleaner before evaporation.

* Repeat this process until the surface is clean, i.e. when there is no visual dirt or contamination transfer onto the cloth.

Ensure the surface is dry and the isopropyl alcohol has completely evaporated before commencing application.

Inpirations of Application

General Maintenance Guidelines

Routine washing is recommended for maximum performance. The following cleaning methods are recommended.

* Wash with sponge, cloth or soft brush using water and detergent.

* Automatic truck/car wash or standard high-pressure hand spray:

Maximum pressure-1200 PSI/ 80 bar.

Maximum water/wash solution temperature- 140°F/ 60°C.

Minimum of 12 inches/ 30cm distance of cleaning jet(s) from markings.

* Cleaning wand or jets to be at no greater angle than 45 degrees from perpendicular to the marking surface.

When using metal brighteners, follow manufacturer’s recommendations for dilution.

When using cleaners/degreasers, make sure the product is suitable for vehicles and follow the manufacturer’s recommendations for dilution. Thoroughly rinse after soaking vehicle. Prolonged exposure to cleaners/degreasers can in some circumstances affect the material negatively. Prolonged exposure in combination with sunlight can reinforce cleaners/degreasers negative effect.

Do not use solvents to clean the film, as they can adversely affect the product. If soap or detergent does not sufficiently clean

the markings, vehicle conspicuity markings (tapes) can be gently rubbed with a cloth soaked in isopropyl alcohol to remove the

stains.

Important:

* The suitability of the intended care process must be determined by the end user.

* Wash with sponge, cloth or soft brush using water and detergent.

* Automatic truck/car wash or standard high-pressure hand spray:

Maximum pressure-1200 PSI/ 80 bar.

Maximum water/wash solution temperature- 140°F/ 60°C.

Minimum of 12 inches/ 30cm distance of cleaning jet(s) from markings.

* Cleaning wand or jets to be at no greater angle than 45 degrees from perpendicular to the marking surface.

When using metal brighteners, follow manufacturer’s recommendations for dilution.

When using cleaners/degreasers, make sure the product is suitable for vehicles and follow the manufacturer’s recommendations for dilution. Thoroughly rinse after soaking vehicle. Prolonged exposure to cleaners/degreasers can in some circumstances affect the material negatively. Prolonged exposure in combination with sunlight can reinforce cleaners/degreasers negative effect.

Do not use solvents to clean the film, as they can adversely affect the product. If soap or detergent does not sufficiently clean

the markings, vehicle conspicuity markings (tapes) can be gently rubbed with a cloth soaked in isopropyl alcohol to remove the

stains.

Important:

* The suitability of the intended care process must be determined by the end user.

Key Words

FMVSS 108

DIN-30710

ASTM D 4956

reflective tape

conspicuity Tape

conspicuity Sticker

trailer reflective tape

tank reflective sticker

truck reflective tape

vehicle reflective vinyl

Conspicuity Marking

FMVSS 108

DIN-30710

ASTM D 4956

cinta reflectiva

cinta de visibilidad

visibilidad Pegatina

cinta reflectante de remolque

pegatina reflectante del tanque

cinta reflectante para camiones

vinilo reflectante del vehículo

Vehicle Conspicuity Marking

FMVSS 108

ASTM D 4956

Fita reflectiva

fita de conspicuidade

Adesivo de conspicuidade

fita reflexiva de reboque

tanque adesivo reflexivo

fita reflexiva de caminhão

vinil refletivo para veículos

application and installation instructions

Hot Searches