- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KUKA CNC

-

Year:

-

2024

-

Voltage:

-

220-500V

-

Dimension(L*W*H):

-

Normal

-

Weight (T):

-

10 T

-

Model Number:

-

Y32

-

Motor Power (kw):

-

22 kw

-

Marketing Type:

-

Construction works

-

Power Source:

-

Hydraulic

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

500

-

Ejector Force (kN):

-

1000

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KUKA CNC

-

Year:

-

2024

-

Voltage:

-

220-500V

-

Dimension(L*W*H):

-

Normal

-

Weight (T):

-

10 T

-

Model Number:

-

Y32

-

Motor Power (kw):

-

22 kw

-

Marketing Type:

-

Construction works

-

Power Source:

-

Hydraulic

Products Description

◆

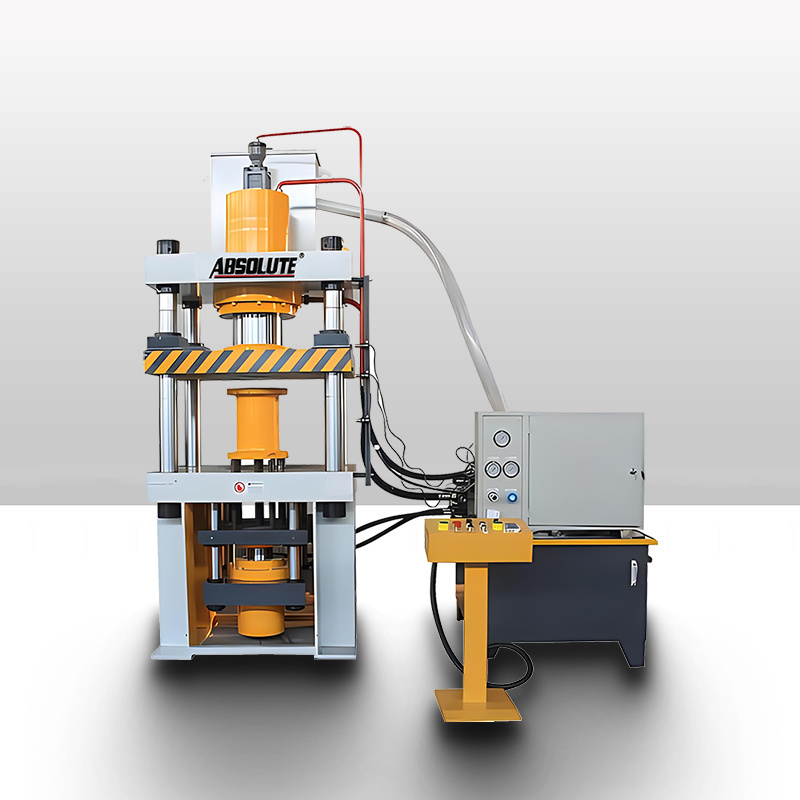

Y32 four-column hydraulic press machine adopts three beams and four columns structure, the hydraulic system adopts cartridge valve oil circuit, the electrical system adopts relay or PLC control circuit, with adjustment and semi-automatic operation mode, the whole machine structure is simple, compact, economic and reasonable, reliable action, long service life, small hydraulic impact, reduce the connection pipeline and leakage. Its working pressure, pressing speed and stroke range can be adjusted within the specified range according to the process needs, and two types of process can be realized: constant pressure and constant range. In the case of fixed-pressure forming, there is a pressure-holding delay and an automatic return stroke after pressing. The table is equipped with an ejector device in the middle, which can be used as a hydraulic pad for the forming process of drawn parts in addition to ejecting the products.

four-column single-movement hydraulic press machine for sheet metal deep drawing adopts a counter-stretching process and the hydraulic pad can be installed in or outside the table. The hydraulic system uses cartridge valves and the electrical system is automatically controlled by PLC. It is equipped with point-action and semi-automatic operation functions, and the stroke, pressure and speed of each moving part are independently adjustable within a certain range to meet the needs of metal products forming parts. It can also be equipped with beating device, moving table, punching and cutting buffer device, grating safety protection device and man-machine interface according to the user's needs.

The Y41 single column hydraulic press is a "C" type single column construction with an all steel welded body. The hydraulic system is arranged in the body and the lower part of the working table is equipped with a hydraulic pad, the working pressure stroke can be adjusted within the specified range. The electrical control system is based on a "PC" programmable controller. The machine is controlled centrally by push-buttons and can be operated in an adjustable, manual or semi-automatic manner. This series of hydraulic presses is suitable for drawing, punching, bending, flanging, correction, pressing, hot and cold extrusion of metal materials, and also for pressing and forming of powder products and plastic products.

This product is suitable for various iron sheets, stainless steel door embossing patterns, large automobile parts and other products. During the press-in process of the product, the current press-fit position and press-fit force are displayed in real time, and the interference amount is judged promptly and accurately whether the size of the interference is appropriate. At the same time, the press-fit curve of the entire force and displacement is displayed, which is a good solution to the traditional The press can only press but not detect, and the testing machine has low efficiency and cannot be mass produced. The overall structure of the equipment has been strengthened and the rigidity far exceeds the standard of ordinary presses, and an overall dust-proof design has been adopted.

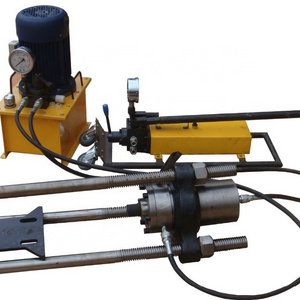

This product is suitable for the press installation of automotive shock absorber assembly, precision bearings, bushings, automotive parts, water pumps, turbochargers, gearboxes, gears, automotive chassis parts, rear axles, subframe bushings, etc. During the press-in process of the product, the current press-fit position and press-fit force are displayed in real time, and the interference amount is judged promptly and accurately whether the size of the interference is appropriate. At the same time, the press-fit curve of the entire force and displacement is displayed, which is a good solution to the traditional The press can only press but not detect, and the testing machine has low efficiency and cannot be mass produced. The overall structure of the equipment has been strengthened and the rigidity far exceeds the standard of ordinary presses, and an overall dust-proof design has been adopted.

Details Images

Some finished product exhibits

Technical Specifications

|

Item

|

|

Unit

|

Y32-63

|

Y32-100

|

Y32-160

|

Y32-200

|

Y32-315

|

Y32-400

|

|

|

Nominal force

|

|

KN

|

630

|

1000

|

1600

|

2000

|

3150

|

4000

|

|

|

Knockout force

|

|

KN

|

160

|

250

|

250

|

400

|

630

|

630

|

|

|

Daylight

|

|

mm

|

800

|

800

|

1000

|

1120

|

1250

|

1250

|

|

|

Slide stroke

|

|

mm

|

500

|

500

|

500

|

710

|

800

|

800

|

|

|

Knockout stroke

|

|

mm

|

200

|

200

|

200

|

250

|

300

|

300

|

|

|

Speed of slide

|

Descent

|

mm/s

|

100

|

120

|

80

|

80

|

120

|

100

|

|

|

|

Pressing

|

mm/s

|

7

|

10

|

6-15

|

5-12

|

5-12

|

4-10

|

|

|

|

Return

|

mm/s

|

85

|

90

|

80

|

70

|

65

|

50

|

|

|

Table area

|

L-R

|

mm

|

550

|

630

|

800

|

900

|

1200

|

1200

|

|

|

|

F-B

|

mm

|

630

|

630

|

800

|

900

|

1200

|

1200

|

|

|

Table height above floor

|

|

mm

|

700

|

700

|

550

|

550

|

700

|

700

|

|

|

Overall dimension

|

L-R

|

mm

|

2370

|

2200

|

2400

|

2450

|

2830

|

2850

|

|

|

|

L-R

|

mm

|

900

|

1200

|

1300

|

1300

|

1500

|

1500

|

|

|

|

Height above floor

|

mm

|

2770

|

2800

|

3200

|

3650

|

4300

|

4400

|

|

|

Motor power

|

|

KW

|

7.5

|

11

|

15

|

15

|

22

|

22

|

|

Corporate field video

Hot Searches