- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QINTAO

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

900X700X1100

-

Weight (KG):

-

200 kg

-

Product Name:

-

QT2-45 cement block machine

-

Working voltage:

-

220v/380v

-

Block Type:

-

Hollow Concrete Brick Machine

-

Forming cycles (S ):

-

45 S/time

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

3400 pcs/8hours, Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QINTAO

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

900X700X1100

-

Weight (KG):

-

200 kg

-

Product Name:

-

QT2-45 cement block machine

-

Working voltage:

-

220v/380v

-

Block Type:

-

Hollow Concrete Brick Machine

-

Forming cycles (S ):

-

45 S/time

Product Description

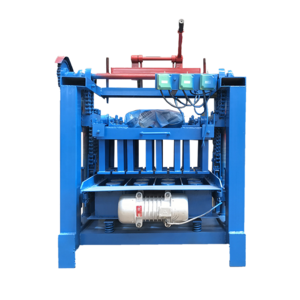

QT2-45

Cement brick making machine

mechanical friction and prolong the service life.

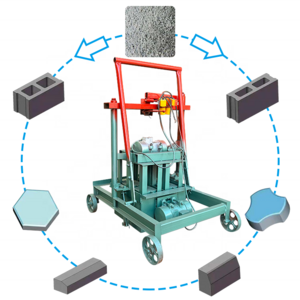

2. After the power is turned on, press the mold lift button to hang the indenter; overlap the mold box and the indenter

several times to check whether it is in order.

3. Press the mold drop button, drop the mold box on the wooden pallet, push the indenter back, and start adding materials

to the mold box, then turn on the lower vibration button and vibrate for 5-8 seconds, stop the vibration and add a little

material, and add more material. The material is scraped to the horizontal position of the mold box.

4. Pull back the indenter to touch the baffle, the hook under the plate will drop the indenter, and turn on the upper and

lower vibration switches at the same time. When the horizontal bars on the two halves of the lead screw reach the

position, turn off the upper and lower vibration buttons. Start the rising button to hang the upper pressure head on the

hook, and stop immediately when it reaches the position to avoid collision. The bricks and pallets can only be pulled out

with a forklift after the hook is firmly hooked.

performance.

2. The mold box adopts column sliding, with compact coordination, synchronous and stable lifting, and the block forming

rate is greatly improved.

3. The pressing head can slide and shift, which is convenient for mould box cloth and greatly improves the efficiency.

4. It is installed on the lifting part of the mold box to prevent the press head from damaging the machine in action.

5. When the vibration is applied, the vibration is excited at the same time, so that the four walls of the mold box are equally

stressed, so as to achieve the forming effect, and ensure that the block density is high, and the edges and corners are

neat and beautiful.

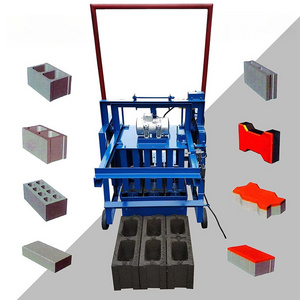

By changing the mold, the small block brick machine can produce: colored pavement bricks, lawn bricks, small concrete hollow blocks, porous bricks, curb stones, wall blocks, etc.

Specification

|

Product name

|

Cement block machine

|

|

Molding cycle

|

45s

|

|

Voltage

|

220v/380v

|

|

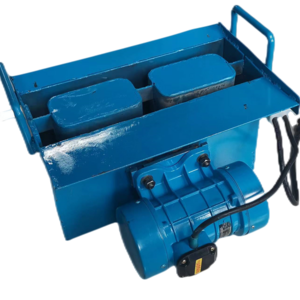

Power

|

0.55kw*2

|

|

Weight

|

220KG

|

|

operator

|

1-2

|

|

Brick shape size

|

240*115*50mm (12 Block/time)

240*190*190mm (2 Block/time)

390*120*190mm (3 Block/time)

390*190*190mm (2 Block/time)

390*150*190mm (2 Block/time)

390*100*190mm (3 Block/time)

|

Packing & Delivery

Hot Searches