- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

QT

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6750x1880x2540mm

-

Weight (KG):

-

8000 kg

-

Plasticity index of raw materials:

-

7-15

-

Moisture water content:

-

20-30%

-

Drying linear shrinkage rate:

-

3-8%

-

Loss on ignition:

-

3-5%

-

Coefficient of drying sensitivity:

-

<2

-

Loss on ignition::

-

3-15%

-

After Warranty Service:

-

Video technical support

Quick Details

-

Type:

-

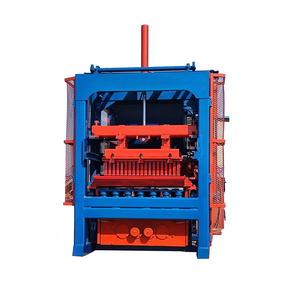

Hollow Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

100000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 240*115*90 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

QT

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6750x1880x2540mm

-

Weight (KG):

-

8000 kg

-

Plasticity index of raw materials:

-

7-15

-

Moisture water content:

-

20-30%

-

Drying linear shrinkage rate:

-

3-8%

-

Loss on ignition:

-

3-5%

-

Coefficient of drying sensitivity:

-

<2

-

Loss on ignition::

-

3-15%

-

After Warranty Service:

-

Video technical support

Best red clay brick making machine/best clay brick machinery

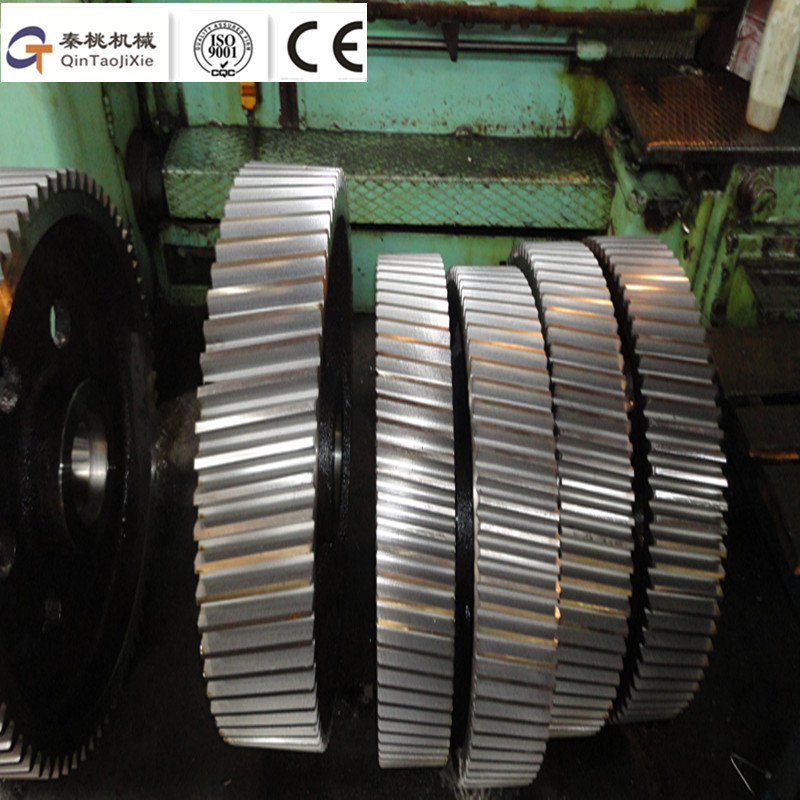

machining production workshop to produce clay brick machine.

Best clay brick machine for clay brick factory

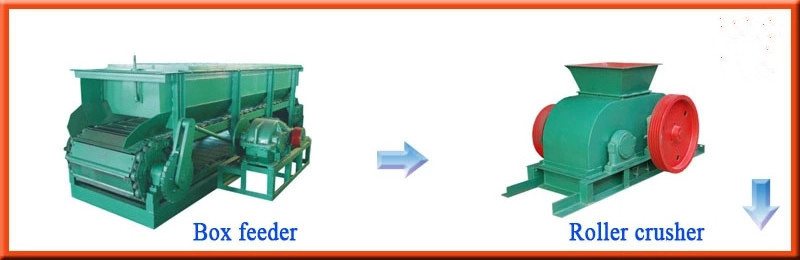

Best clay brick machine for clay brick making process,including many different clay brick machinery.

FullyAuto Clay brick factory with red clay brick machinery

1. Raw material & fuel preparation and handling

1)The molding water content rate should be controlled within 16%-18%. clay brick machine

1)When the unfired bricks cut by cutter and arranged into groups. clay brick machine

2)unloading system The properly burned bricks .

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(4) provide the offer, flow chart, and detail specification of each clay brick machine.

(1)Quality of clay brick machine control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

CONTACT US