- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

A*B*C

-

Weight:

-

8000

-

Power (kW):

-

18

-

history:

-

more than 30 years with professional technology

-

Advantage1:

-

without oil spiliing or off pressure

-

Advantage2:

-

low noise and high safety

-

Operation:

-

1 Person

-

Control System:

-

PLC+touch Screen

-

Crimping force:

-

200T- 600T

-

After-sales Service Provided1:

-

Free spare parts

-

After-sales Service Provided2:

-

Field maintenance and repair service

-

After-sales Service Provided3:

-

Online support

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GUANGYUE

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

A*B*C

-

Weight:

-

8000

-

Power (kW):

-

18

-

history:

-

more than 30 years with professional technology

-

Advantage1:

-

without oil spiliing or off pressure

-

Advantage2:

-

low noise and high safety

-

Operation:

-

1 Person

-

Control System:

-

PLC+touch Screen

-

Crimping force:

-

200T- 600T

-

After-sales Service Provided1:

-

Free spare parts

-

After-sales Service Provided2:

-

Field maintenance and repair service

-

After-sales Service Provided3:

-

Online support

-

Marketing Type:

-

Ordinary Product

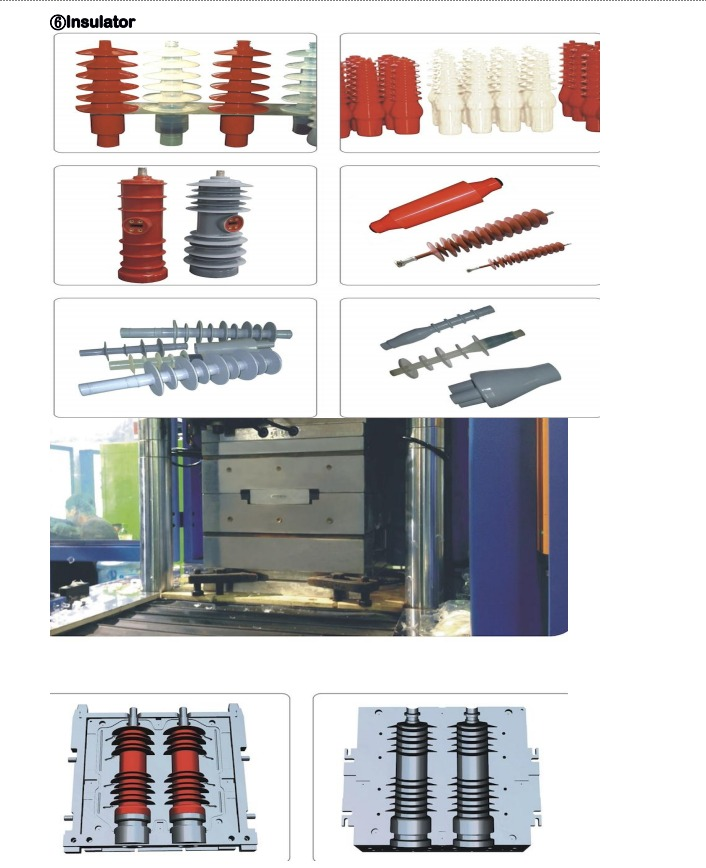

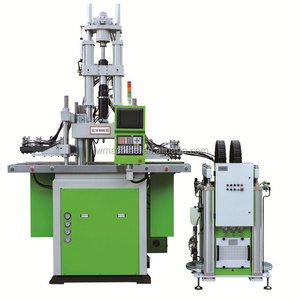

Rubber injection molding machine

automatic150T 4RT Rubber injection molding machine

we can also offer you the different injection machine as your request,evem the material is different,including silicone ,rubber and plastic injection machine

1.Horizontal rubber injection molding machine

Features:

High excellent rate of finished-products,with less and even burrs,almost perfect,suitable for precise and complicated products.It is the best choice for high quality demand.

Applications:

Polyin.polyhedron,and complicated products.Especially applied in sports,medical,automobile,electronic and electrical products.

| No. | parameters | 200Ton | Remark |

| 1 | Clamping force | 200Ton | infinite amount of the rubber |

| 2 | Heating plate size | up:560mm×560mm | |

| 3 | down:560mm×560mm | ||

| 4 | Heating plate qty | 2pcs | |

| 5 | Mode of heating | Electrical heating | 0-250℃ |

| Between any adjustable | |||

| 6 | Temperature control mode | Intelligent digital display meter | Intelligent digital display number |

| 7 | Piston diameter | Φ355mm | material:Cold hard alloy |

| 8 | Number of cylinder | 1set | |

| 9 | Heating plate space between | 300mm | Can be adjusted to400mm |

| 10 | Maximum stroke of master cylinder | 300mm | |

| 11 | Big pillar | 90mm | |

| 12 | System operating pressure | 20Mpa | |

| 13 | Structure form | Four-post type | |

| 14 | Hydraulic system | Specific pressure specific flow circuit | |

| 15 | Control mode | PLC | |

| 16 | Pressure setting mode | Sensor control | |

| 17 | motor power | Oil pump power:7.5KW | Rubber injection machine:15KW |

2.Horizontal silicon rubber injection molding machine

Features:

Large quantity of plastic injection, high degree of automation

Applications:

Electricity transmission and distribution products,Insulation products.

3.FIFO type rubber injection machine

High injecting temperature ,shorter vulcanizing time

Features:

1.The first plasticized rubber material goes into the mold cylinder first during injection,which means FIrst In First Out. This saves production time

2.Provide big work table

3.Imported double-proportional trunk piston oil pump can do any actions without impact

4. Save 25-50 % motor energy cost

5.Three sections of injection pressure,flow and pressure holding satisfy any products' technological requirements

6.PLC programmable controller and touch screen make it easy to set up,view and save technological parameters.It can also supervise the whole producing ,auto diagnose inner fault and give an alarm

7.Protect with safe light curtain

8.Precisely fix mold in and out positon

9.Control material temperature

10.Temperature control precision is between + 1 celsius degree

4.The vacuum heat presses to modle the machine

Suitable for the production of various k inds of O ring, rubber

keyboard, rubber parts for medical use, Vehicle rubber parts, the most

economical traditional machine type, can choose a total of three layers

of die mold

Structural property:

1.Tha machine structure after the computer pressure ,the strain analysis ,the srevice life is long-time;

2.The special heating platen design,the temperature distribution is even,guarantees the formation quality disposable;

3.The fluctuation track organization ,guaranteed that the sliding panel and the heating platen do not rub;

4.The high efficiency fast vacuum system ,the end product lack materials,the gas-free does not s oak.

Hydraulic system:

The hydraulic pressure unit and an organism body,the design is artistic, not oil leak,may also choose the proportion type pressure,the current capacity system

Electrical system

The PLC matching touches the screen control,enhances the product quality stablity .

the products samples:

.

welcome to our factory