- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

1.5

-

Range of Spindle Speed(r.p.m):

-

400 - 440 r.p.m

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ancourage

-

Voltage:

-

3~380v

-

Dimension(L*W*H):

-

410mm*480mm*890mm

-

Weight (KG):

-

140 KG

-

Marketing Type:

-

2023 New Type

-

Sample Type:

-

Hard,Medium-hard,Brittle

-

Feed Size:

-

≤20mm

-

Collector capacity/Through put:

-

3L/150Kg/h

-

Gap with setting:

-

0.1-12mm, continuous, Precision of digital display 0.01mm

-

Speed:

-

440rpm

-

W*H*D:

-

Approx.410mm*480mm*890mm

-

Net weight:

-

Approx.140Kg

-

Electrical parameters:

-

3~380V/1500W

Quick Details

-

Output (kg/h):

-

5 - 60 kg/h

-

Feeding Size (mm):

-

0.01 - 20 mm

-

Output Size (mesh):

-

100 - 155 mesh

-

Power (kW):

-

1.5

-

Range of Spindle Speed(r.p.m):

-

400 - 440 r.p.m

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ancourage

-

Voltage:

-

3~380v

-

Dimension(L*W*H):

-

410mm*480mm*890mm

-

Weight (KG):

-

140 KG

-

Marketing Type:

-

2023 New Type

-

Sample Type:

-

Hard,Medium-hard,Brittle

-

Feed Size:

-

≤20mm

-

Collector capacity/Through put:

-

3L/150Kg/h

-

Gap with setting:

-

0.1-12mm, continuous, Precision of digital display 0.01mm

-

Speed:

-

440rpm

-

W*H*D:

-

Approx.410mm*480mm*890mm

-

Net weight:

-

Approx.140Kg

-

Electrical parameters:

-

3~380V/1500W

Product Description

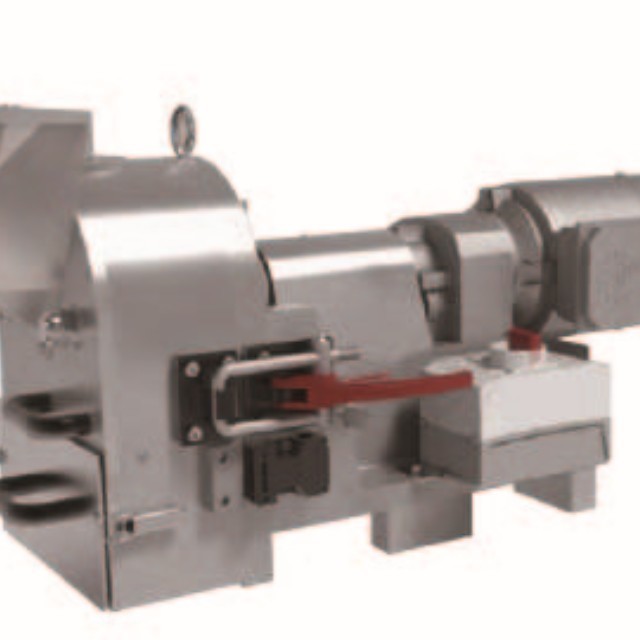

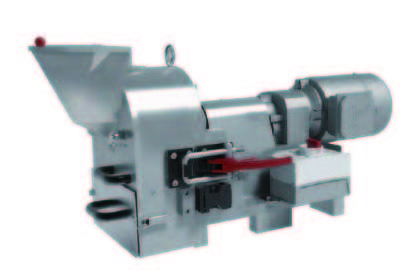

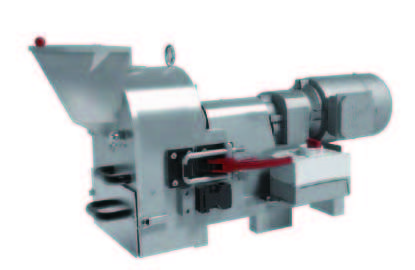

AM800 Disc Mill

AM800 Disc mill is used for batchwise or continuous

preliminary and fine size reduction of mediumhard to hard-brittle solids. The disc mill can grind such

sample materials to an average final fineness of approx. 100μm in one go.

Basic Info.

|

Model

|

AM800 Disc Mill

|

|

Sample Type

|

Hard,Medium-hard,Brittle

|

|

Feed Size

|

≤20mm

|

|

Final Fineness

|

<100μm(Depending on the nature of the sample)

|

|

Collector capacity/Through put

|

3L/150Kg/h

|

|

Gap with setting

|

0.1-12mm, continuous, Precision of digital display 0.01mm

|

|

Speed

|

440rpm

|

|

W×H×D

|

Approx. 410mm×480mm×890mm

|

|

Net weight

|

Approx. 140Kg

|

|

Electrical parameters

|

3~380V/1500W

|

Design Feature

•

The repeatability of the results was achieved by precisely adjusting

the gap width of the grinding disc.

•

Extremely short grinding time, the fineness of the material can reach

D90<100μm.

•

Hard sample grinding, feed size up to 20mm.

•

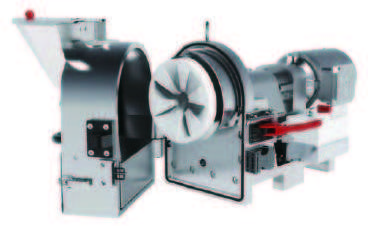

Grinding chamber door can be opened to facilitate cleaning with

vacuum cleaner interface.

•

No dust is produced during the grinding process.

•

Safety lock device to ensure the safety of the experiment.

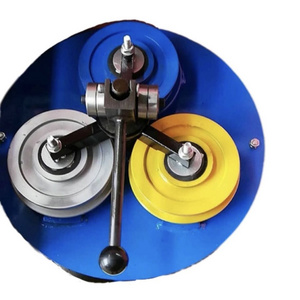

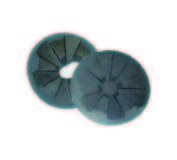

Selection of grinding disc

Manganese steel

Zirconium oxide

Zirconium oxide

The material should be selected so that contamination of the sample and unwanted abrasion are avoided. 4 different materials are available:

•For standard size reduction

e.g. Minerals with Mohs hardness 3-6.

•Grinding disc set made from hardened steel or manganese steel.

•For extreme size reduction

e.g. Minerals with Mohs hardness >6 grinding disc set made from tungsten carbide (WC).

•For heavy-metal-free size reduction

e.g. Dental ceramics grinding disc set made from zirconium oxide.

After a long period of use the grinding discs will show signs of mechanical wear. However, before they need to be replaced by new ones, the opposite side of the teeth can also be used by changing the direction of rotation of the motor. This considerably extends the working life of the grinding discs.

Related Products

AM100S Vibratory Ball Mill

AM500S High speed rotary mill

AM750S Bench Jaw Crusher

AM300S Cutting mill

AF100S Vibratory Sieve Shaker

AF300 Vibratory Feeder

Hot Searches