- Product Details

- {{item.text}}

Quick Details

-

Item:

-

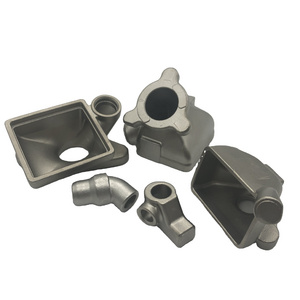

China Cheap Commercial Competition Steel Cast

-

Material:

-

steel 45, Q235, ss304,ss306,G35, G45, WCB, WCA, WCC, 4140, etc

-

Manufacturing Process:

-

Lost wax casting, Investment casting

-

Casting Tolerance:

-

CT4-8 for carbon steel casting with machining

-

Machining Process:

-

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

-

Machining Tolearnce:

-

Up to IT7, Ra 0.8~3.2 , according to customer requirement

-

Surface Treatment:

-

Surface Passivatin, Polish. As customer requests.

-

Package of steel casting:

-

Multi-layer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

About 50 days for carbon steel casting with machining

-

Service:

-

Supply metal parts solution as per Customers drawings/ samples

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Defang

-

Model Number:

-

DF-24119

-

Item:

-

China Cheap Commercial Competition Steel Cast

-

Material:

-

steel 45, Q235, ss304,ss306,G35, G45, WCB, WCA, WCC, 4140, etc

-

Manufacturing Process:

-

Lost wax casting, Investment casting

-

Casting Tolerance:

-

CT4-8 for carbon steel casting with machining

-

Machining Process:

-

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

-

Machining Tolearnce:

-

Up to IT7, Ra 0.8~3.2 , according to customer requirement

-

Surface Treatment:

-

Surface Passivatin, Polish. As customer requests.

-

Package of steel casting:

-

Multi-layer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

About 50 days for carbon steel casting with machining

-

Service:

-

Supply metal parts solution as per Customers drawings/ samples

Specification

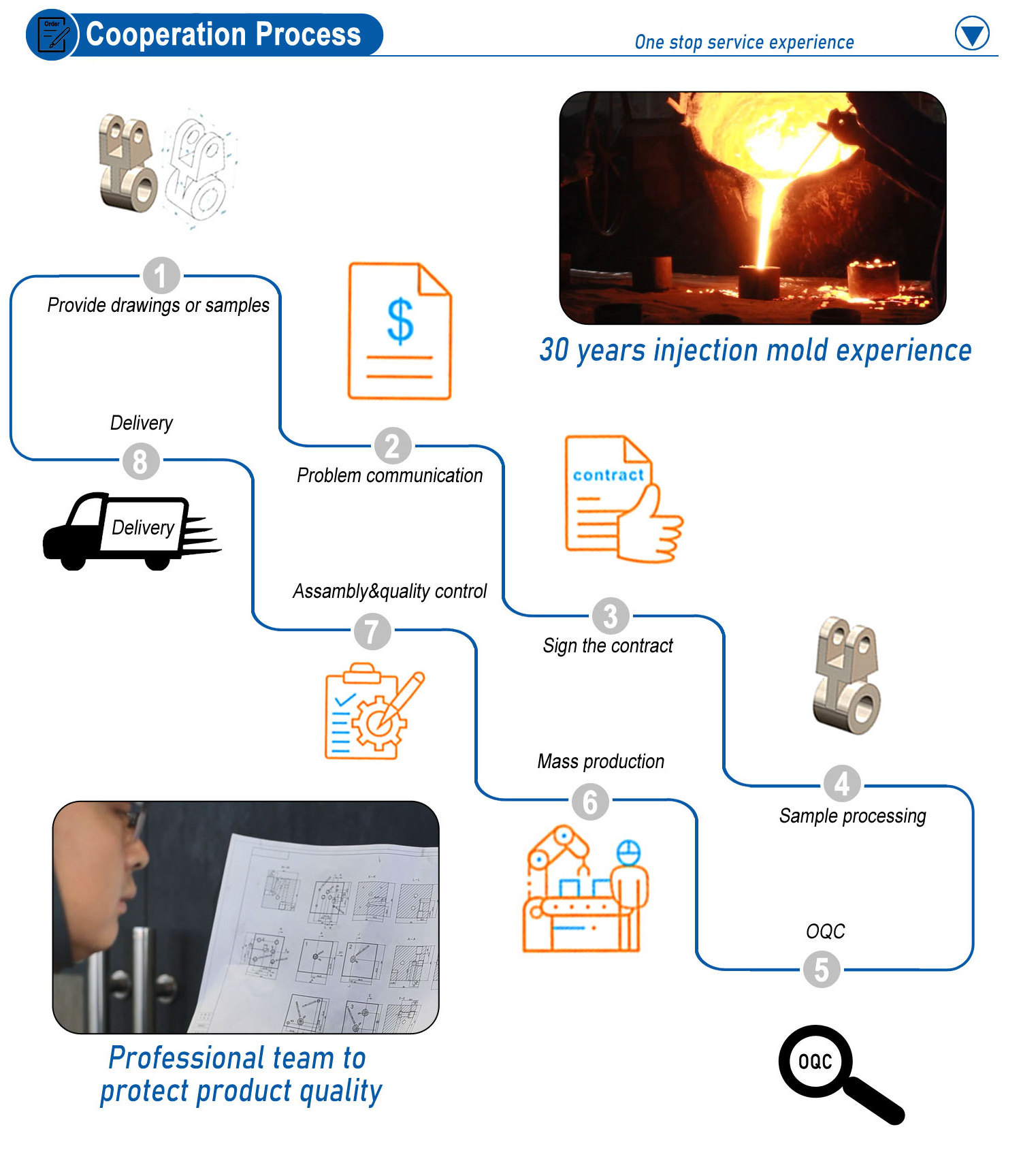

WITH NEARLY 30 YEARS OF CASTING PROCESSING EXPERIENCE

JUST CONTACT US TO GET BEST QUOTATION:

|

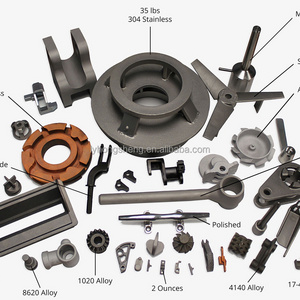

item

|

value

|

|

Material

|

Carbon Steel /customzied

|

|

Application

|

auto parts/ truck parts/ construction machinery parts /agricultural vehicle parts/ mechanical equipment parts/ machine tools /hardware and so on

|

|

Process

|

Casting +Machining(if Need)+surface Treatment

|

|

Machining Process

|

Machining Center

|

|

Heat treatment

|

Tempering/Customized

|

|

Manufacturing Process

|

Sand Casting/Customized

|

|

Service

|

Customized OEM

|

|

Quality Control

|

ISO/TS16949:2002 ISO9001

|

|

Surface treatment

|

Customers' Demand

|

Why Choose Us

Q: Are you a factory or trading company?

A: Defang is an injection mold factory in Shandong of China, welcome to visit us.

Q: How can l get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days.Inorder to quote for you earlier, please provide us the following information together with yourinquiry.

1)3D Step of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5)Any special demands or requirements, such as packing, labels,delivery,etc.

Q: What are the main oversea markets of Defang?

A: Currently Defang regular oversea customers are from the US, the UK, ltaly, Germany, Franceand India etc.

Q: How you do the quality control?

A:1). Materials inspection by lQC;

2).The first sample inspected by QC, QC will do over check as per the parameters list and criticaldimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure noany rejects;

4). FQC will check the products before sending to the warehouse;

5).100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: lf receive defective product, please send us the photos, we will feedback to our engineers andQC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A:1).For moulds, we will be coated one-layer anti-rust oil first,and then also will be covered thin filmson the mould , finally pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer's request to pack.

Hot Searches