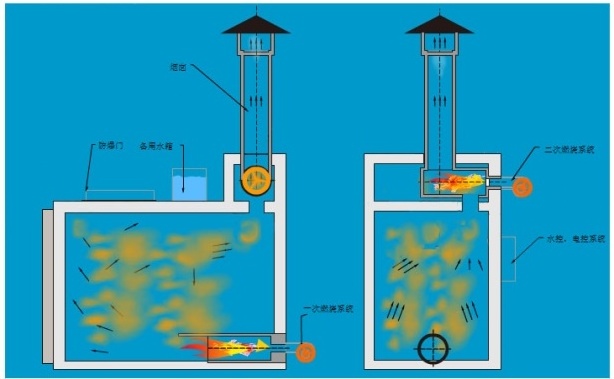

First of all, the workpieces are loaded on the trolley, and sent into furnace manually, then close the furnace door, automatic processing is completed by hot cleaning furnace according to the program. Hot cleaning furnace consists of two relatively independent heating system as well as the temperature, smoke control system. Heating system heats the furnace chamber within the range of 450℃. The smoke control system strictly controls the concentration in the furnace and chimney, make qualified exhaust emissions.

Temperature is stepped up, rising velocity is calculated by the microcomputer, and is controlled by computer. Surface organic matter decomposition step by step into a gas, when the decomposition (gas) to combustion system after 750℃~1150℃ high temperature treatment into CO2 and water vapor through the chimney, the remaining inside the furnace is artifacts and is not affected by the temperature of inorganic matter. Inorganic has into powder, just tap the or rinse immediately with water to remove. The material of workpiece performance remains the same.