-Rotary capping turret, suitable to the application of screw plastic caps on PET bottles

-The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads.

-The heads are raised and lowered by the action of a follower that is riding on a shaped cam

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99.8%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SOKOS

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

can filling machine

-

Function:

-

Filling and Sealing

-

Usage:

-

Beverage Packaging

-

Material:

-

SUS304

-

Filling material:

-

Flowing Liquid

-

Bottle type:

-

Metal, Plastic

-

Capacity:

-

Customized

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Wood, Other

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≥99.8%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SOKOS

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

can filling machine

-

Function:

-

Filling and Sealing

-

Usage:

-

Beverage Packaging

-

Material:

-

SUS304

-

Filling material:

-

Flowing Liquid

-

Bottle type:

-

Metal, Plastic

-

Capacity:

-

Customized

Automatic beer can filling line machine, can filling and sealing machine, can filling machine

1. Model GF12

2.Capacity : 1500CPH (500ml)

3. Suitable : Plastic bottle 250ml-2000ml

4.Machine electric brand : SIEMENS , MITSUBISHI, Schneider

5.Machine power : 2.5KW

6. Machine include function : Filling,Sealing.

7. Application: Beverage, water , beer , juice , oil.

|

Model

|

GF12-2

|

GF18-4

|

GF24-6

|

GF32-8

|

|||

|

Capacity

|

1500-2000cans/hour

|

2000-3500CPH

|

4000-6000CPH

|

8000-10000CPH

|

|||

|

Can Volume

|

200-550ml

|

18

|

24

|

|

|||

|

Can diameater

|

50-70mm

|

30-250cans/min

|

30-300cans/min

|

|

|||

|

Bottle high

|

120-170mm

|

Φ52.5 -99mm

|

Φ52.5 -99mm

|

|

|||

|

Machine power

|

1.5KW

|

2.2KW

|

3.7KW

|

5.5KW

|

|||

Video of test machine for automatic can filling and sealing line.

This video will show you how to clean the inside and outside of the can, pour beer into the can, cover and seal the can.

Final Products

|

Equipment Type

|

Automatic

|

|

Bottle Type |

PET /Aluminum /Tin can

Volume 200 - 550ml Can diameter Φ50-70mm Can height 120-170mm |

|

Output

|

up to 10000Cph

|

|

Your product

|

Beverage juice / tea and hot filling juice .etc

|

|

Certificates

|

CE / ISO 9001

|

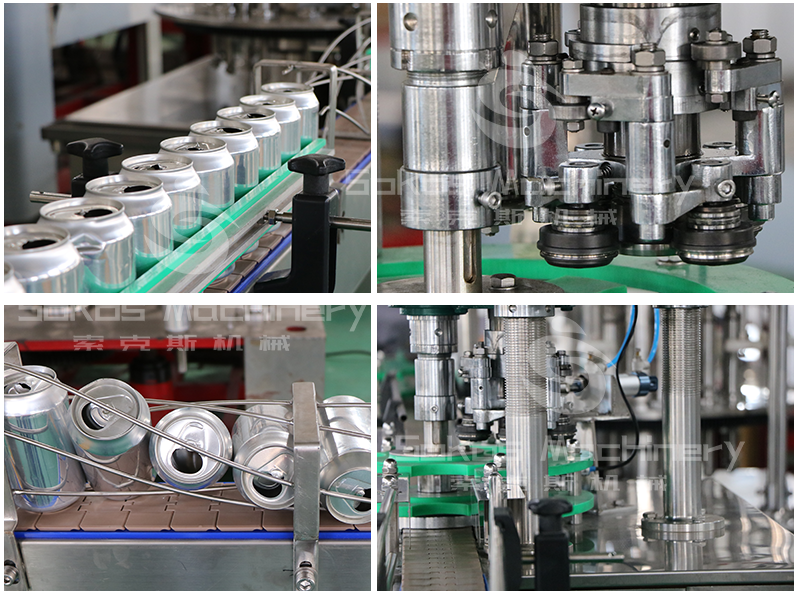

Machine Details

Automatic bottling filling machine energy drink beer can filling machine.

Filling Parts-

filling beer/cola into bottle

Automatic bottling filling machine energy drink beer can filling machine.

Capping Parts-put metal caps on tin can

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.15%

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.15%

Conveyor System

Tipping conveyor system

- Air filter is positioned at every entrance of air fan, to prevent dust blown into cans.

- cans are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

Flat Conveyor

-The conveying system is designed one-to-one according to the customer's factory layout.

-Adopt a special lubrication system,

equipped with an overload protection system, effectively guarantee the safe and fast operation of the whole line

CIP Cleaning system

The purpose of sterilization and cleaning is achieved through the steps of hot water above 60°C-alkaline washing-solution

cleaning-underwater sterilization.

cleaning-underwater sterilization.

Machine Advantage

Accessories are all stainless steell

-Filling machine air conveyor SUS304-Cleaning part of SUS304

-Filling tank and nozzle SUS316

-Capping head SUS304

-Rack SUS304

-Filling machine flat conveyor SUS304

-Filling tank and nozzle SUS316

-Capping head SUS304

-Rack SUS304

-Filling machine flat conveyor SUS304

Electrical appliances-Siemens

-Touch screen :SIEMENS

-PLC :SIEMENS

-Inverter:SIEMENS

-AC contactor :SIEMENS

Detail of Sokos Machine

After-sales system

Logistics system

1: The machine is packaged in standard export packaging, using membrane cloth and wooden boxes.

2: It is only an hour's drive from

the port of Shanghai, an international metropolis, and the logistics is very convenient.

the port of Shanghai, an international metropolis, and the logistics is very convenient.

Custom drawings

1: The company has 8 engineers with more than 20 years of experience

2: 1 to 1 design drawings for customers 3: All equipment is supervised and tested by designed engineers to ensure the quality of machinery delivery

Quick response

1: 24 months warranty.

2: Many-to-one service, solving basic problems through phone calls, emails, whatsapp, WeChat, and video calls. The operation manual will be sent with the machine or by e-mail.

Hot Searches