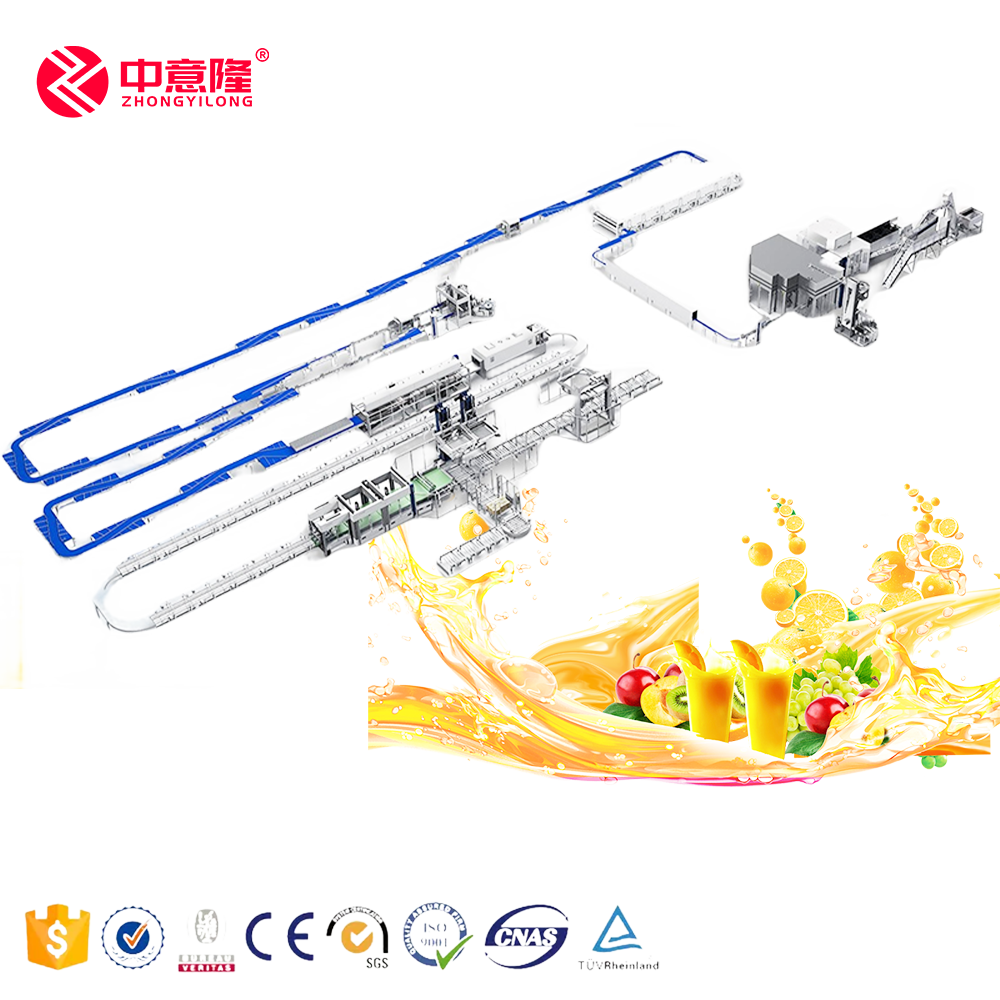

Thanks for your inquiry on Alibaba. ZHONGYILONG Machienry co.,ltd. have been specializing in food&beverage processing line for many years and successfully set up 300 factories for demestic and international customers.

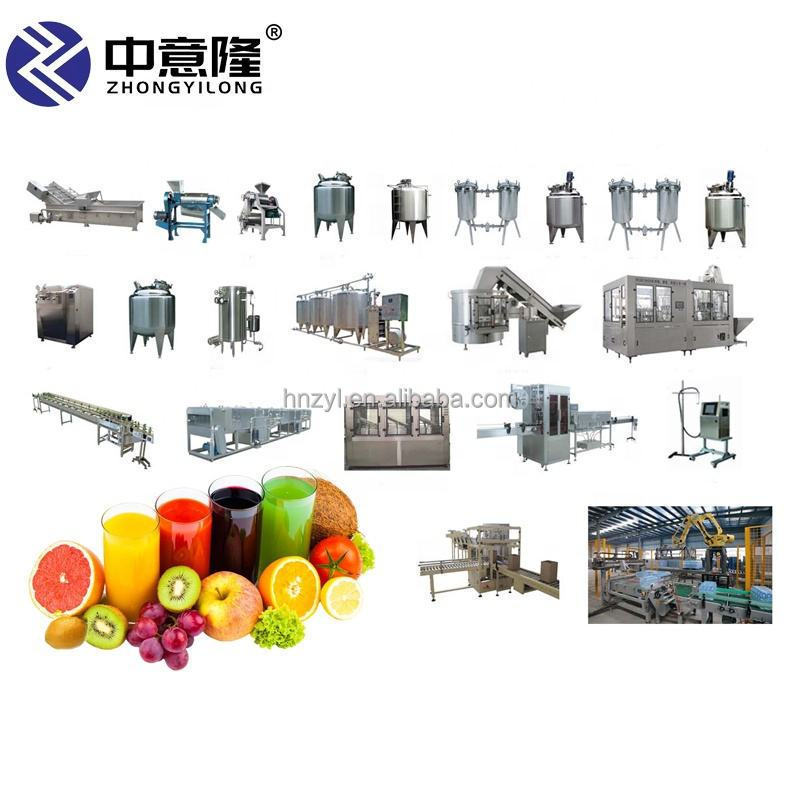

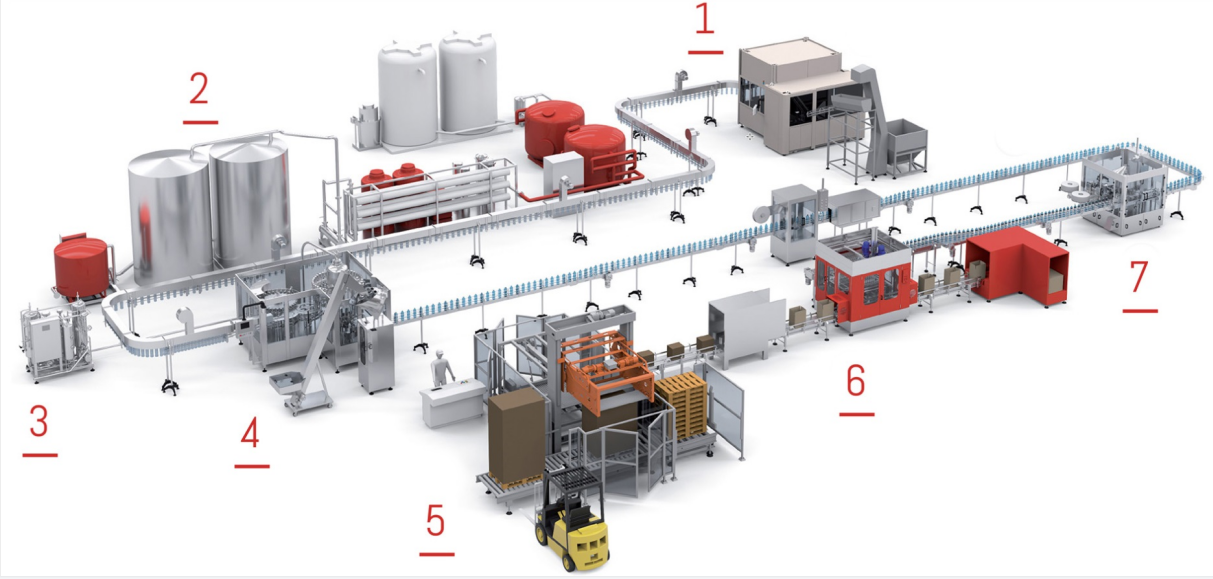

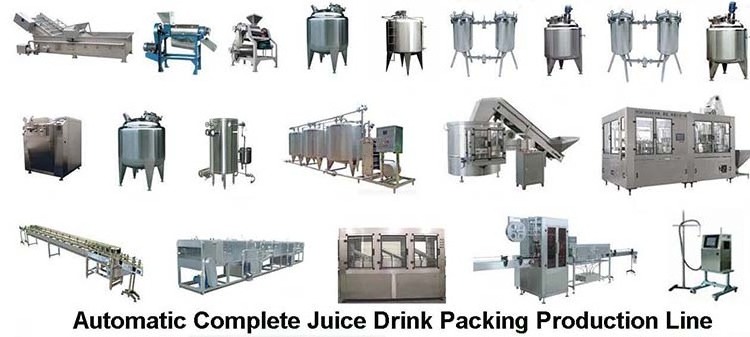

we are a high-tech manufacturing enterprise focusing on automatic packaging production equipment for food, beverage, medicine and electronic products. We can customize beverage production line process and formula according to customer's demand.

Our business scope covers dairy products, carbonated beverages, wine, beer, fermented beverages tomato paste, porridge, mixed juice drinks, vitamin functional drinks, pure water.cooking oil production lines, etc.

We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

We look forward to your inquiry and exchange cooperation.

To generally understand your requirement and facilitate our further communication, we'd like to know from you:

1.Will this be your own business or you are trading company?

2.what will be the scale of this project: home-scale ,commerical-scale or government procurement?

3.By which process: you already have process flowchart or we design for you?

4.what's the final products?

package and product specification detail

5.what's the estimated capacity?

input of raw material or output of final products, how much, by hour/daily or annual?

6.What's stage of this project are you in?

gathering information for future inspection

or want to finish this project in half or one year?

Please kindly understand that we will work very closely with you to offer an turn key solution.So firstly we should fully comprehend your situation in order to make out a reasonable project scheme with affordable cost.

Looking forward to your early response.