- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

500 KG

-

Model:

-

LBJQ-800 Robot Stacker

-

Maximum stacking height:

-

2500MM

-

Weight of Automamtic Robot Stacker:

-

2500kg

-

Speed of Carton Palletizer Machine:

-

800-900bags/hour

-

Palletizing model:

-

2+3 2*3

-

Power of Robot Pallet izer:

-

8kw

-

Pallet material::

-

wood, steel, plastic or other composite materials

-

Recommended pallet size::

-

1400*1200*150-160mm

-

Recommended pallet size:2:

-

1200*1100*150-160mm

-

Certification:

-

CE of Robot Stacker

Quick Details

-

Application:

-

Food, Beverage, Commodity

-

Packaging Material:

-

Other

-

Place of Origin:

-

Henan, China

-

Weight:

-

500 KG

-

Model:

-

LBJQ-800 Robot Stacker

-

Maximum stacking height:

-

2500MM

-

Weight of Automamtic Robot Stacker:

-

2500kg

-

Speed of Carton Palletizer Machine:

-

800-900bags/hour

-

Palletizing model:

-

2+3 2*3

-

Power of Robot Pallet izer:

-

8kw

-

Pallet material::

-

wood, steel, plastic or other composite materials

-

Recommended pallet size::

-

1400*1200*150-160mm

-

Recommended pallet size:2:

-

1200*1100*150-160mm

-

Certification:

-

CE of Robot Stacker

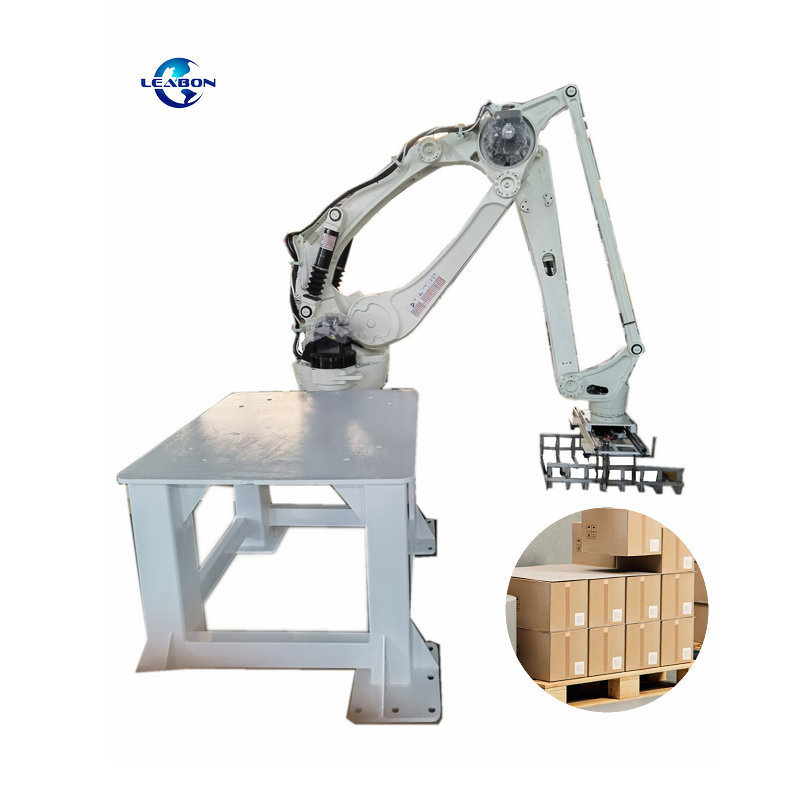

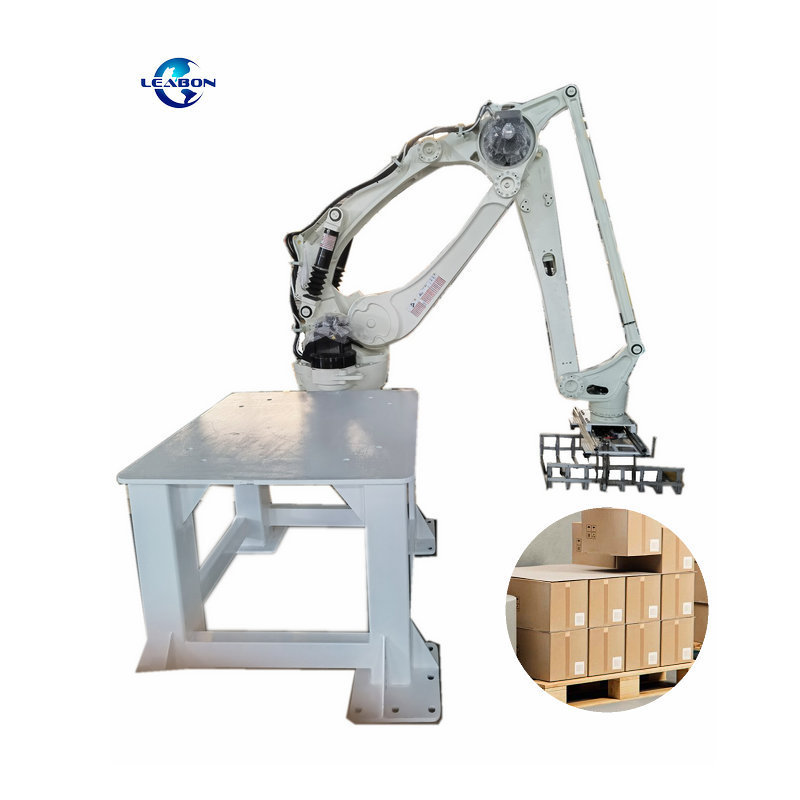

Factory Price Automatic Carton Box Bagging Robot Palletizer Machine Water Juice Bottle Box Automatic Robot Stacker

Product Description

Introduction- full automatic carton pallerizer:

palletizing robot palletizer is a kind of specialized and integrated industrial equipment. The robot will be packed into the pallet or box layer by layer according to a predetermined marshalling method.

It is usually used as a follow-up equipment of the packaging line, with high production capacity and transshipment capacity.

palletizing robot palletizer is a kind of specialized and integrated industrial equipment. The robot will be packed into the pallet or box layer by layer according to a predetermined marshalling method.

It is usually used as a follow-up equipment of the packaging line, with high production capacity and transshipment capacity.

Specification

|

Model

|

LBJQ-800 Automatic Robot Palletizer

|

|

Maximum stacking height

|

2500mm

|

|

Maximum palletizing weight

|

2500kgs

|

|

Speed of Palletizing Carton Palletizier

|

Max 800-900bags/hour

|

|

Power of Bag Stacking Machine

|

8KW

|

|

Palletizing model

|

2+3 shape; 2X3 shape etc

|

|

Pallet material:

|

wood, steel, plastic or other composite materials (specific structure and material provided by the user);

|

|

Recommended pallet

size: |

1400mm long×1200mm wide×150~160mm high or 1200mm long×1100mm wide×150~160mm high;

|

Applicate for Palletizing Different Kind of Raw Material : Bag, Carton, Box , Case, Water/Juice Bottle etc..

Details Introduction for Whole Automatic Robot System

1. Inverted bag conveyor

The vertical bag passes through the packaging machine, sewing machine and conveyor and enters the vertical inverting conveyor. Through the detection of the photoelectric switch, it is judged whether the bag has reached the position of pushing the bag; at the same time, the photoelectric switch of the lower horizontal conveyor is used to detect whether there is a bag The necessary conditions such as the safety distance to push down, if all the conditions are met, the PLC drives the relay→solenoid valve→cylinder action to push the bag down into a horizontal state for transportation.

2. Robot Gripper

Whenthe product to be palletized is transported to the grabbing line and the photoelectric switch senses that the product is in place,

and the palletizing position photoelectrically senses that there is a pallet to be palletized at the pallet position, the

palletizer program drives the servo motor to move the flange with the gripper into place. The gripper solenoid valve is driven,

the air cylinder is actuated, and the gripper puts the bags on the tray in an orderly manner.

and the palletizing position photoelectrically senses that there is a pallet to be palletized at the pallet position, the

palletizer program drives the servo motor to move the flange with the gripper into place. The gripper solenoid valve is driven,

the air cylinder is actuated, and the gripper puts the bags on the tray in an orderly manner.

3. Grab Conveyor

The packaging bags are transported from the press-packing conveyor to the grabbing conveyor and palletized with the robot. Ensure the safe and convenient grabbing of the palletizing robot and reduce noise.

4. Shaping Conveyor

The product is conveyed by the vibration of the square roller, the packaging bag is more flat, and the palletizing is neat and beautiful; at the same time, the reshaping conveyor can spread the product at a certain distance, which is convenient for photoelectric detection and subsequent palletizing;

5. Packing Conveyor

Through the vibration conveying of the square roller, the packaging bag passes through the pressing conveyor at the same time to reshape the packaging bag, so that the products in the packaging bag are uniform and the palletizing pattern is more neat and beautiful.

Related Equipments

Full Automatic High Lever Palletizer for Bag, Carton,Box, Water, Juice, Brick, Etc.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches