- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

34m*4.55m*3.2m

-

Power (kW):

-

130

-

Weight (KG):

-

5000 KG

-

Name:

-

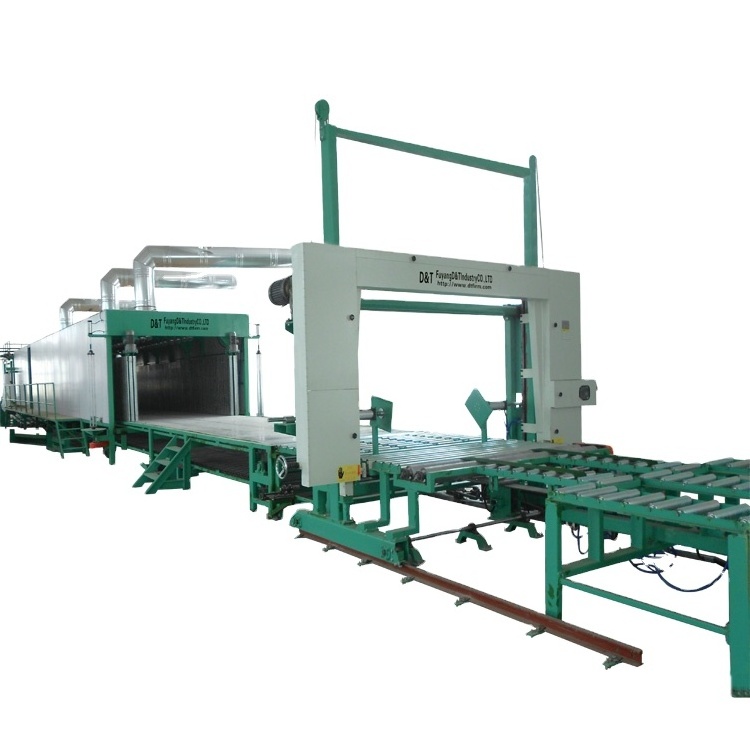

Full Automatic continuous foaming machine to make Polurethane foam

-

Overall dimension:

-

34m*4.55m*3.2m

-

Product Height:

-

below 1200MM

-

Product Width:

-

1200mm~2300mm

-

Density:

-

10Kg/m3~50Kg/m3

-

Capacity:

-

2000mm/min~7000mm/min

-

Maximum capacity:

-

200~300L/min

-

application area:

-

sponge, polyurethane foam, mattress, furniture

-

Certificate:

-

CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

D&T

-

Machine Type:

-

continuous foaming machine

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

34m*4.55m*3.2m

-

Power (kW):

-

130

-

Weight (KG):

-

5000 KG

-

Name:

-

Full Automatic continuous foaming machine to make Polurethane foam

-

Overall dimension:

-

34m*4.55m*3.2m

-

Product Height:

-

below 1200MM

-

Product Width:

-

1200mm~2300mm

-

Density:

-

10Kg/m3~50Kg/m3

-

Capacity:

-

2000mm/min~7000mm/min

-

Maximum capacity:

-

200~300L/min

-

application area:

-

sponge, polyurethane foam, mattress, furniture

-

Certificate:

-

CE

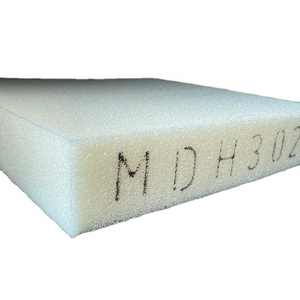

After foaming, it needs 6 hours for cooling and curing in the ventilated warehouse.

Product Description

A. specifications of each component:

1.Stirs mix rack and spongy control platform: 4m×3.2m×3.2m(L×W×H)

2. Drop board of drying tunnel 8.32m×1.2m~2.30m(L×W)

3.Side link joint of drying tunnel 17.5m×2.4m×1.2m(L×W×H)

4.Rack of drying oven 16.9m×4.55m×3.2m(L×W×H)

5. Level transportation line in the drying tunnel 17.5m×2.4m×0.8m(L×W×H)

6. The width of sponge wadding for cutting machine 2.4m×1.30m (W×H) (Undercut type)

B. main technical specifications and functions

1. Overall dimension of the equipment: 34m×4.55m×3.2m(L+total width+ H)

2. Quantity of component of foaming material: 13 groups

3. Product Width: 1200mm~2300mm

4. Product Height: ≤1200MM

5. Density: 10Kg/m³~50Kg/m³

6. Capacity: 2000mm/min~7000mm/min

7. Maximum capacity: 200~300L/min

8.Method of Foaming: 1). down spurts, sway (up, down, front, or back adjustable)

2). trough type (match 2 foaming troughs: W1550mm/w2100mm)

9. Membrane lift installment (Flat topping function)

10. Announcing arrestor for material lack( foaming protect function)

11. Drop board of drying tunnel operated height and width by electrically

12. Transportation line of side link joint of drying tunnel operated height and width by electrically

13. The body paper and film put away automatically

14. Easy to change the two mix stirs (Φ100mm) and pre-mixer

15. The Method to control expanding:

1).Control by PLC, kinds of different types of sponge continuously once

2).Entire transducer control, production line synchronization;

16. The Maximum Size of the sponge: 1500mm×2300mm×1300mm(L×W×H).

17. The electrical machinery power of mix stirs: 37kw

18. Total Power: 130kw