- Product Details

- {{item.text}}

Quick Details

-

Max. temperature:

-

1200c

-

working temperature:

-

1100c

-

heating element:

-

resistance wire

-

thermocouple:

-

K type

-

temperature controller:

-

PID controller

-

temperature accuracy:

-

1 C

-

furnace details:

-

can be designed as your requirement

-

warranty:

-

1 year

-

payment:

-

T/T, L/C

Quick Details

-

Brand Name:

-

Kejia

-

Model Number:

-

KJ-1200 CVD

-

Place of Origin:

-

Henan, China

-

Max. temperature:

-

1200c

-

working temperature:

-

1100c

-

heating element:

-

resistance wire

-

thermocouple:

-

K type

-

temperature controller:

-

PID controller

-

temperature accuracy:

-

1 C

-

furnace details:

-

can be designed as your requirement

-

warranty:

-

1 year

-

payment:

-

T/T, L/C

KJ-1200CVD system is a special RTP tube CVD system designed for laboratory graphene growthing, coating thin film on the metal foil, especially for preparing flexible electrode on metallic foil on new generation energy research. Fast heating and cooling can be achieved by sliding the furnace.

Dual quartz tube:100mm dia. outside tube and suspended by 80 mm diameter tube inside. Metallic foil will be wrapped around interior tube surface for CVD reaction.

Vacuum sealed flanges for dual tube, which allow reactive gas to go through between two tubes ( 10mm space ) for reaction, and inert gas to go through center tube for cooling.

2 gas channels controlled by 2 separate digital MFC's

High speed mechanical vacuum pump is included with KF25 adapter and pipe

Sliding rail is installed on the bottom

of furnace, which allows for fast heating or cooling by sliding furnace from one side to the other side.

Specifications:

| Furnace Structure |

High purity Al2O3 insulation chamber grantees excellent temperature uniformity.

|

| Power | Power: 208-240VAC, 50/60Hz, single phase, 2.5KW ( 20A Breaker required) |

| Heating Temperature |

Max. Temperature: 1200°C

Continuous Temperature: 1100°C |

| Heating Zone |

Heating zone length: 440mm

Constant temperature heating zone length: 120 (±1°C) @400~1100°C

The tube diemater and the heating zone length, heating zone number is customized! All the furnace details can be designed with your requirememt.

|

| Heating & Cooling Rate |

Max. heating and cooling rates depend on working temperature. you can move the furnace chamber to get high cooling & heating rate. |

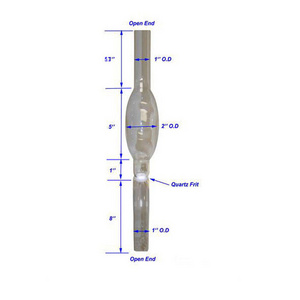

| Fused Quartz Tube |

Outer tube: OD: 4"x ID: 3.8"X 58.3" Length (OD100 x ID 96 x 1480 mm )

Inner tube: OD:3.15: x ID x 2.95" x 60.6" Length (OD80 x ID 75 x 1540 mm ) |

|

One pair of flange made of SS304, which seals tightly between tubes by double high temperature O-rings to achieve high vacuum.

|

|

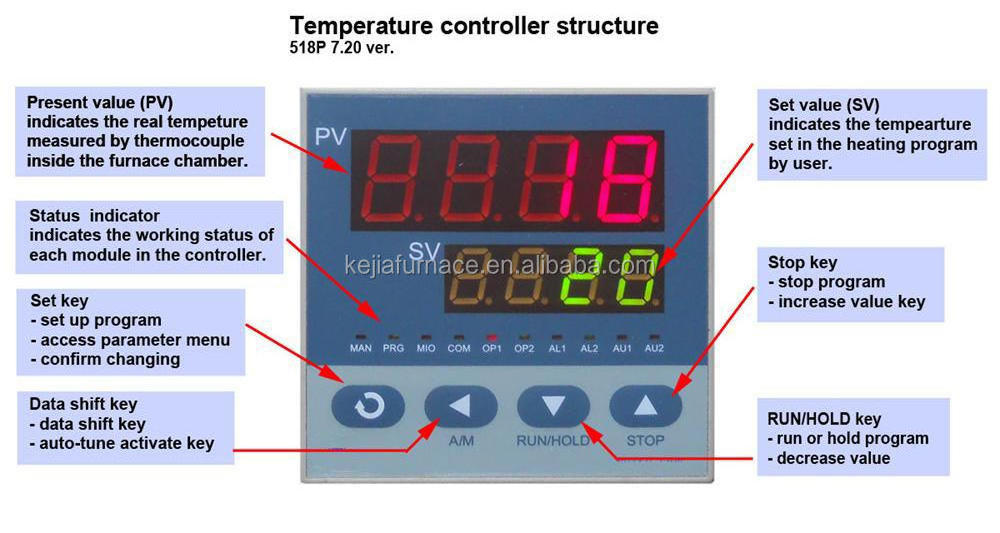

| Temperature Controller |

Temperature Controller: 30 segment programmable with PID tuning & Over temperature protection.

Also can design the controller with your requirement. |

| Gas Mix Station |

Four precision mass flow controller ( MFC) with digital display are installed on the bottom case to control gas flow rate automatically.

Flowing rate accuracy: 0.2% accuracy Gas inlet and outlet: 1/4" swagelok tube connector One gas mixing tank is installed on bottom case with liquid release valve. Each gas route has a SS needle valve to on-off control independently. The flow rate is adjustable in the MFC panel.

|

| Vacuum Pump |

Heavy Duty Rotary Vane Vacuum Pump (7.8 CFM -240 L/m) with Two Stage Exhaust System installed inside the vacuum station. vacuum pressure 10

-2

Torr.

KFD25 adapter and stainless steel pipe are connected between pump and tube flange with a right-angle vacuum valve . Digital vacuum pressure gauge and display are installed with the furnace. Optional: 1. You may choose low vacuum dry vacuum pump for zero contamination. 2. You may choose molecular pump at extra cost to reach high vacuum pressure up to 10-5 Torr. |

|

25um Thickness Copper Foil

as Substrate (optional) |

Copper Foil for Graphene Growth (150m length x 150mm width x 25um thickness) - EQ-bccf-25u:

|

| Dimension |

Furnace: 550 x 380 x 520

Bottom Mobile case: 600x600x597 |

| Net Weight | 300 lb |

| Warranty | One year limited warranty (Consumable parts such as processing tubes, o-rings and heating elements are not covered by the warranty.) |

| Certificate | CE certified |

CE certificate

Contact information:

Contact person: Tanya Wang

Mobile: 0086 18137195603; 13526477203 for 24 hours

Skype: tanyawang55

QQ: 912950531

Other related products that we can supply