- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

custom made

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

Actual Size

-

Purity:

-

99.9%

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After-sales Service:

-

Engineers available to service machinery overseas

-

Technology:

-

Cryogenic Liquid Process

-

Feature:

-

Provide PLC / DCS control

-

Package:

-

Wooden Box packing

-

Method:

-

Use structured packing

-

advantage 1:

-

simple on-site installation

-

advantage 2:

-

convinient transportation

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CYY ENERGY

-

Production Rate:

-

99.6%

-

Voltage:

-

custom made

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

Actual Size

-

Purity:

-

99.9%

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After-sales Service:

-

Engineers available to service machinery overseas

-

Technology:

-

Cryogenic Liquid Process

-

Feature:

-

Provide PLC / DCS control

-

Package:

-

Wooden Box packing

-

Method:

-

Use structured packing

-

advantage 1:

-

simple on-site installation

-

advantage 2:

-

convinient transportation

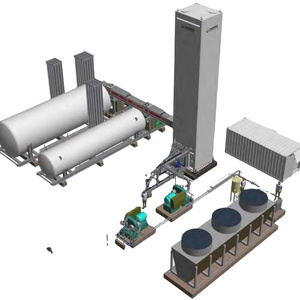

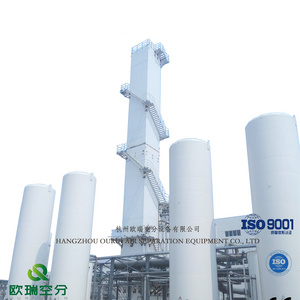

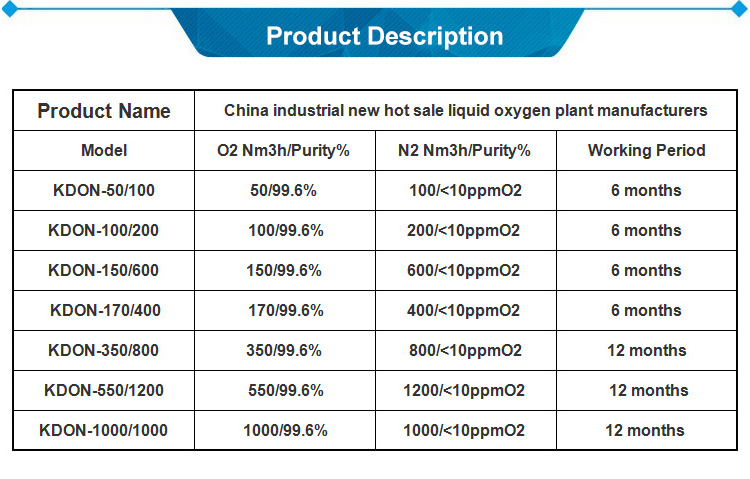

New arrival cryogenic liquid oxygen air separation plant

We are a professional gas equipment and solutions supplier and have more than 10 years experience in industrial gas equipment.Zhejiang ChengYingYi Cryogenic Equipment Co.,Ltd. is a high-tech enterprise dedicated to research and development, production and sales of air seperation plant and natural gas equipment. Our main products include air separation plant, natural gas liquefaction plant,PSA/VPSA oxygen and nitrogen generator,gas filling stations, cryogenic liquid storage tanks, cryogenic pumps, vaporizers,etc.CYY possesse top-level technical design capabilities, mature project management system, high-quality production process, and professional sales and after-sals service team.

The company has established good business cooperation relationship with many world-renowned companies, such as Linde Group, Messer Group, Air Products, Halliburton, Taiyo Nippon Sanso, Iwatani Gas, Chiness Academy of Sciences and so on. So far, the company has successfully provided a large number of equipment and solutions to customers in more than 40 countries and regions around the world, and has become one of the world's leading gas equipment manufacturers.

We offer a wide range of PSA oxygen/nitrogen gas generators to be installed onsite for all industrial oxygen/nitrogen applications. Our oxygen/nitrogen gas generators are based on the well-known PSA (Pressure Swing Adsorption) technology using two pressurized columns with molecular sieves providing your business with unlimited oxygen/nitrogen generation on demand.

| PSA | ||

| parameters | Oxygen | Nitrogen |

| Gas production | 5-200Nm³/h | 5-3000Nm³/h |

| Purity | 70-94% | 95-99.999% |

| Export pressure | 0.1-0.5MPa | 0.1-0.8MPa |

| Atmospheric pressure dew point | ≤-40℃ | |

VPSA (vacuum pressure swing adsorption) oxygen production equipment mainly consists of blower, vacuum pump, oxygen adsorption tower, balance tank, switching valve and PLC control system. The raw material air is pressurized by the blower, cooled by the cooler, adsorbed by the adsorption tower, and desorbed by the vacuum pump to finally separate the oxygen from the raw air.

| VPSA | |

| Oxygen production | 100-10000Nm³/h |

| Oxygen purity | 50-94%(Adjustable) |

| Oxygen consumption | 0.30-0.38KWh/Nm³ when the purity of oxygen is 93% |