- Product Details

- {{item.text}}

Quick Details

-

Power:

-

12.4KW

-

Weight:

-

480 KG

-

Dimension(L*W*H):

-

2120*1360*1590mm

-

Year:

-

2021

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINKAI

-

Voltage:

-

220/380V

-

Power:

-

12.4KW

-

Weight:

-

480 KG

-

Dimension(L*W*H):

-

2120*1360*1590mm

-

Year:

-

2021

-

MOQ:

-

1 Set

Product Description

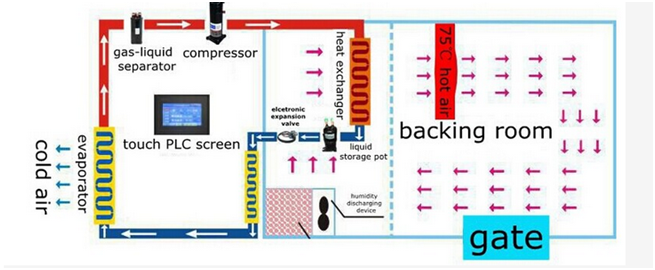

WORKING PRINCIPLE OF HEAT PUMP DRYER

Conventionally, materials are dried either in the field (sun drying) or using high temperaturedryers(electric, gas fired, etc.). Successful outdoor drying depends upon good weather and indeterminateweather can render a product worthless.

High temperature drying can damage the nutrient content andimpart an unpleasant smell to the dried product.Specialty crops such as ginseng, herbs, echinacea, etc..need to be dried at low temperatures (30 - 45Celsius degree) for product quality optimization. This is animportant consideration as they have a relatively high commercial value. Heating ambient air to use fordrying, although a simple cost-effective procedure, is of limited application, particularly at higher ambientair relative humidities because of the low allowable maximum temperature conditions, Under high ambientmoist air conditions, it may not even be possible to dry the material by conventional means. Hightemperature drying deterlorates the materlal structure and can render it unsuitable for further use. Lowtemperature drying of specialty crops reduces the risk of loss in nutrient content and damage to physicalpropertles. Drylng system lncorporating a dehumidifcatlon cycle have been developed that both conserveenergy and handle the material gently. The dryer operates using a heat pump where both sensible andlatent heats are recovered from the exhaust air, The heat is then recycled back through the dryer byheating the air entering the dryer. The KINKAl heat pump drying system is a combination of two sub-systems: a heat pump and a dryer, also the equipment have 2times waste heat recovery.

KINKAl heat pump dryer operates according to a basic air conditioning cycle involving four maincomponents: the evaporator,the compressor, the condenser and the expansion valve.The working fiuid(refrigerant) at low pressure is vaporized in the evaporator by heat drawn from the dryer exhaust air. Thecompressor raises the enthalpy of the working fuid of the heat pump and discharges it as superheated

Advantages

Details Images

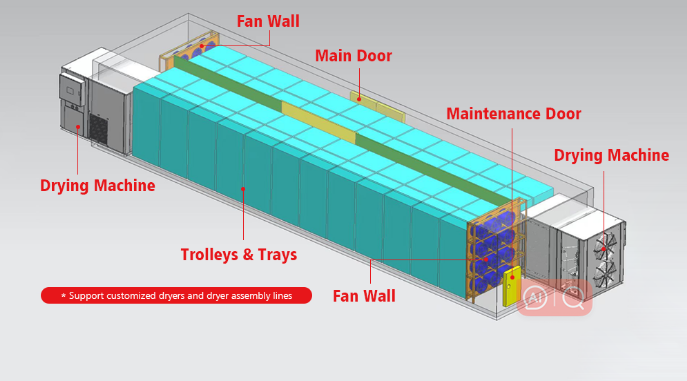

Dryer

Fan Wall

Baking Room

Trolleys & Trays

Application cases

Chili Drying project

After the peppers are washed and dried, a cleaning machine, air dryer, and dryer are required to put them into the curing room. After drying it can be ground and packaged.

Wood Drying project

The wood needs to be naturally dried for a long time before being artificially dehumidified and dried. For different textures of wood, drying methods are also different.

Lemon Drying project

The lemons are washed, sliced and placed in the dryer. After drying, they are vacuum packed and refrigerated.

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Other

|

|

Showroom Location

|

Canada, Viet Nam, Sri Lanka

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2021

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Pump

|

|

Condition

|

New

|

|

Place of Origin

|

Guangdong, China

|

|

Brand Name

|

KINKAI

|

|

Voltage

|

220/380V

|

|

Power

|

12.4KW

|

|

Weight

|

480KG

|

|

Dimension(L*W*H)

|

2120*1360*1590mm

|

|

Year

|

2024

|

|

Warranty

|

1 Year

|

Hot Searches