- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.5kw

-

Dimension(L*W*H):

-

710*520*900mm

-

Weight:

-

100 KG

-

Marketing Type:

-

New Product 2023

-

Application:

-

Dumpling Machine

-

Final product:

-

Dumpling/Samosa/Empanada/Spring Roll

-

Material:

-

Stainless Steel

-

After-sales Service Provided:

-

Online Service Support

-

Processing Types:

-

Grain Procesing Machine

-

Advantage:

-

Easy Operation High Efficiency

-

Feature:

-

High Efficiency Easy Operate

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUNJIN

-

Voltage:

-

220V/110V

-

Power:

-

2.5kw

-

Dimension(L*W*H):

-

710*520*900mm

-

Weight:

-

100 KG

-

Marketing Type:

-

New Product 2023

-

Application:

-

Dumpling Machine

-

Final product:

-

Dumpling/Samosa/Empanada/Spring Roll

-

Material:

-

Stainless Steel

-

After-sales Service Provided:

-

Online Service Support

-

Processing Types:

-

Grain Procesing Machine

-

Advantage:

-

Easy Operation High Efficiency

-

Feature:

-

High Efficiency Easy Operate

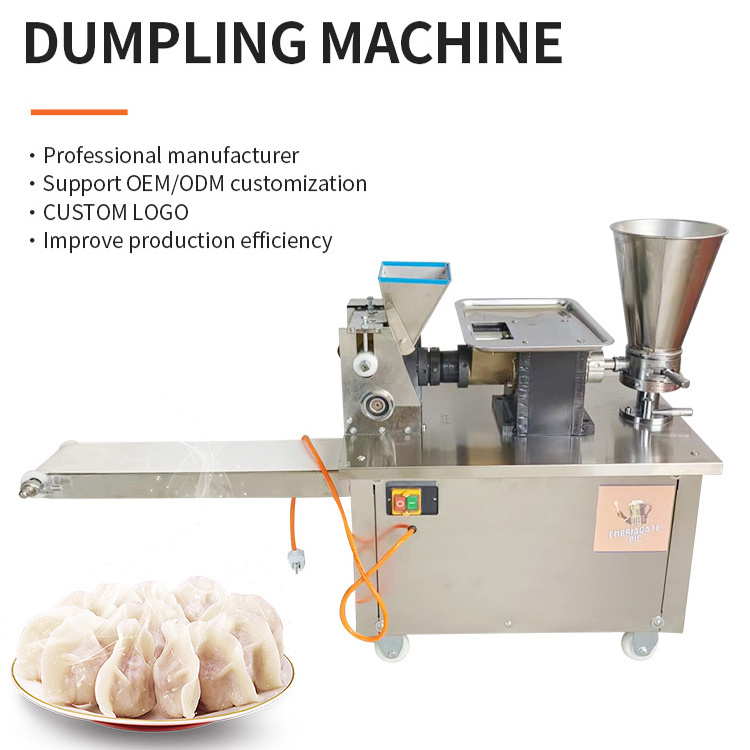

Introduction about Dumpling machine:

Dumpling machine is also called dumpling machine, automatic dumpling machine. It mainly refers to putting the mixed dough and the stuffing into the designated inlet of the machine, and then turning on the machine to produce finished dumplings. This machine has the advantages of fast production speed, high finished product, saving time and labor, etc.; it is widely used in restaurants ,canteens, schools, enterprises and institutions, and fast food and dumpling processing industries. The dumpling machine is a type of food processing equipment. The dumplings it processes are one of the traditional delicacies of northern China. Its main purpose is to replace the manual process of making dumplings and improve work efficiency.

Dumpling machine features:

1. Dumpling machine equipment This machine adopts the molding characteristics of simulating the sheeting and wrapping of hand-made dumplings, and the principle of dual-control and bi-directional quantitative feeding. There is no need to make additional dumpling wrappers during production. You only need to put the dough and fillings into the feed port. It can automatically produce dumplings when it is turned on.

2. According to the requirements of pastry technology, the friction with the dough is minimized to ensure that the dumplings have a soft texture and good elasticity. The dumplings are beautiful in appearance and have a good three-dimensional feel,which is comparable to handmade dumplings.

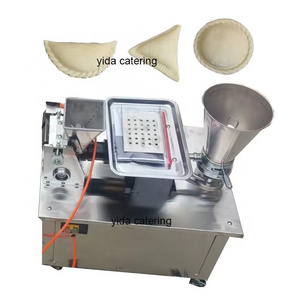

3. One machine has multiple uses. As long as the mold is changed, pastries of different shapes and specifications can produced. Such as spring rolls, wontons, hot pot dumplings, pearl dumplings, curry puffs, lace dumplings, pot sticker dumplings, etc.

4. Suitable for a variety of cooking: the dumplings can be steamed, boiled, fried or pan-fried. Spring rolls, samosas and curry puffs are especially delicious when fried. The most important thing is that they are suitable for rapid freezing and storage resistance, making them ideal microwave food.

5. The size of the products is uniform, and the thickness of the dough, the amount of fillings, and the speed of making dumplings can be adjusted at will. 5, you can operate it freely. One or two people with no experience can operate the machine.

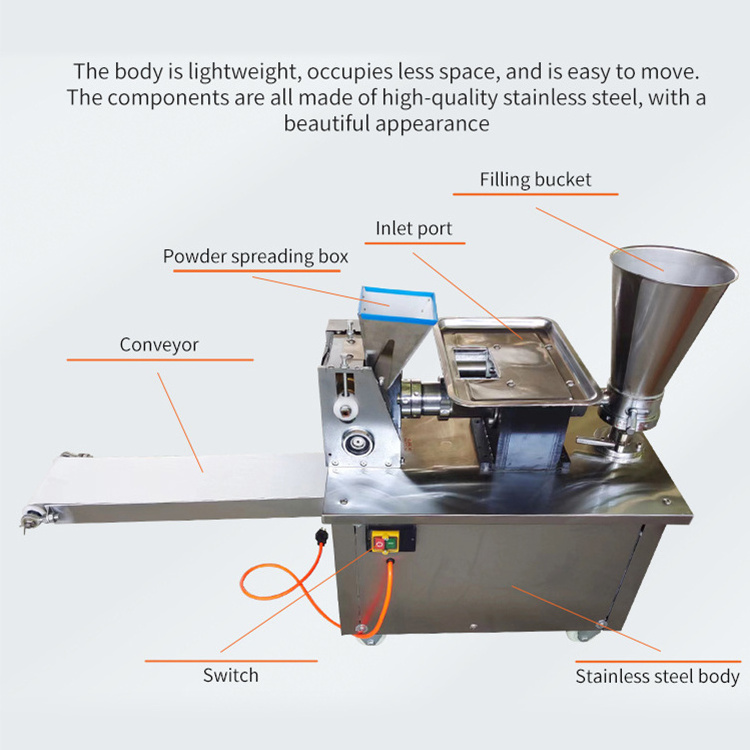

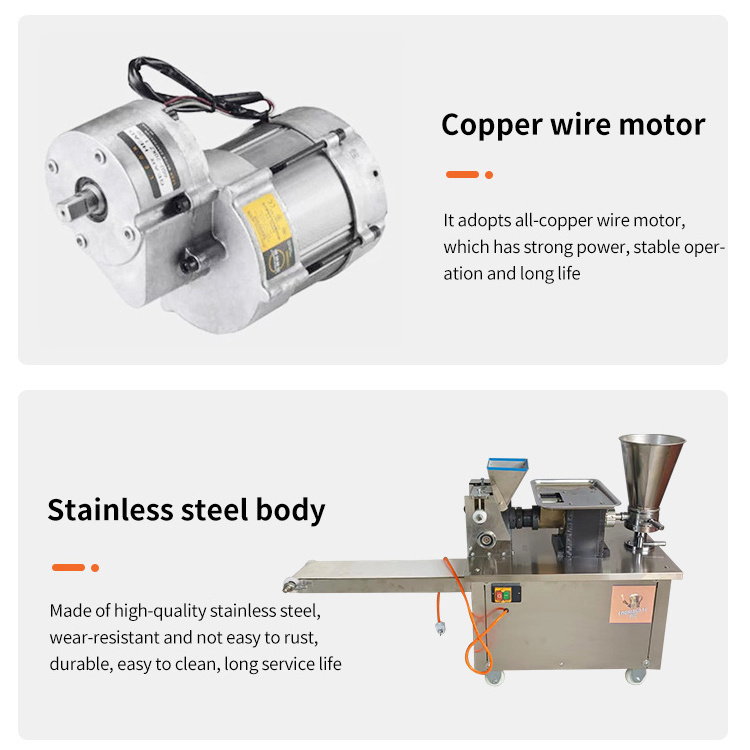

6. The body is lightweight, takes up less space, and is easy to move. The main parts are made of high-quality stainless steel,with beautiful appearance and in line with International food hygiene standards.

7. The conveying surface and molding parts adopt special anti-adhesion technology, which has low resistance, good molding, and is easy to maintain, disassemble and clean.

8. Suitable for making dumplings with meat fillings, mixed meat and vegetable fillings, whole vegetable fillings and other fillings. Suitable for various working environments.

9. High work efficiency, equivalent to 8 to 12 workers making dumplings by hand at the same time, truly low investment, high efficiency, saving money and labor.

Dumpling machine is also called dumpling machine, automatic dumpling machine. It mainly refers to putting the mixed dough and the stuffing into the designated inlet of the machine, and then turning on the machine to produce finished dumplings. This machine has the advantages of fast production speed, high finished product, saving time and labor, etc.; it is widely used in restaurants ,canteens, schools, enterprises and institutions, and fast food and dumpling processing industries. The dumpling machine is a type of food processing equipment. The dumplings it processes are one of the traditional delicacies of northern China. Its main purpose is to replace the manual process of making dumplings and improve work efficiency.

Dumpling machine features:

1. Dumpling machine equipment This machine adopts the molding characteristics of simulating the sheeting and wrapping of hand-made dumplings, and the principle of dual-control and bi-directional quantitative feeding. There is no need to make additional dumpling wrappers during production. You only need to put the dough and fillings into the feed port. It can automatically produce dumplings when it is turned on.

2. According to the requirements of pastry technology, the friction with the dough is minimized to ensure that the dumplings have a soft texture and good elasticity. The dumplings are beautiful in appearance and have a good three-dimensional feel,which is comparable to handmade dumplings.

3. One machine has multiple uses. As long as the mold is changed, pastries of different shapes and specifications can produced. Such as spring rolls, wontons, hot pot dumplings, pearl dumplings, curry puffs, lace dumplings, pot sticker dumplings, etc.

4. Suitable for a variety of cooking: the dumplings can be steamed, boiled, fried or pan-fried. Spring rolls, samosas and curry puffs are especially delicious when fried. The most important thing is that they are suitable for rapid freezing and storage resistance, making them ideal microwave food.

5. The size of the products is uniform, and the thickness of the dough, the amount of fillings, and the speed of making dumplings can be adjusted at will. 5, you can operate it freely. One or two people with no experience can operate the machine.

6. The body is lightweight, takes up less space, and is easy to move. The main parts are made of high-quality stainless steel,with beautiful appearance and in line with International food hygiene standards.

7. The conveying surface and molding parts adopt special anti-adhesion technology, which has low resistance, good molding, and is easy to maintain, disassemble and clean.

8. Suitable for making dumplings with meat fillings, mixed meat and vegetable fillings, whole vegetable fillings and other fillings. Suitable for various working environments.

9. High work efficiency, equivalent to 8 to 12 workers making dumplings by hand at the same time, truly low investment, high efficiency, saving money and labor.

How to use the dumpling machine

Turn on the power and test run;After cleaning and restoring the installation, we can turn on the power and start the machine. Before turning on the power, place the stuffing pump clutch handle in the parked position and use a hook wrench to move the dough auger to the rear end. Check whether the connected power supply is consistent with the rated voltage and number of items of the machine. Only after confirming that they are consistent can the power be turned on. After starting, check whether the machine has leakage and judge whether the steering is correct according to the direction of rotation of the molding die. If the machine is rotated outward, it is correct.

After seeing that the machine is operating normally, idle for 3 to 5 seconds. During operation, turn the machine in the indicated direction. Check the clutch handle and adjustment handle to see if there are any abnormalities. Wait until the machine runs normally before starting to use it.

Turn on the power and test run;After cleaning and restoring the installation, we can turn on the power and start the machine. Before turning on the power, place the stuffing pump clutch handle in the parked position and use a hook wrench to move the dough auger to the rear end. Check whether the connected power supply is consistent with the rated voltage and number of items of the machine. Only after confirming that they are consistent can the power be turned on. After starting, check whether the machine has leakage and judge whether the steering is correct according to the direction of rotation of the molding die. If the machine is rotated outward, it is correct.

After seeing that the machine is operating normally, idle for 3 to 5 seconds. During operation, turn the machine in the indicated direction. Check the clutch handle and adjustment handle to see if there are any abnormalities. Wait until the machine runs normally before starting to use it.

|

Power

|

Capacity

|

Power

|

Weight

|

Package weight

|

Size(mm)

|

Package Size(mm)

|

|

2.5kw

|

3600/h

|

220V/110V

|

100kg

|

110kg

|

640*440*810

|

710*520*900

|

Hot Searches