- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to different models.

-

Weight:

-

According different models. to

-

Product Name:

-

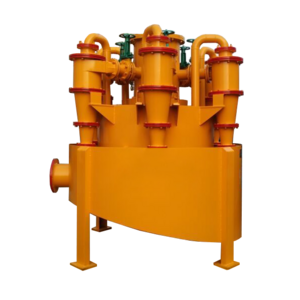

Fluidized bed separator

-

Material:

-

Carbon Steel & Ceramic Liner

-

Color:

-

Customized Making

-

Application:

-

Coal Mining

-

Local Service Location:

-

Peru, India, Russia, Australia, South Africa

-

After-sales Service Provided:

-

Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

ISO

Quick Details

-

Production Capacity:

-

20000 sets per year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Haiwang

-

Dimension(L*W*H):

-

According to different models.

-

Weight:

-

According different models. to

-

Product Name:

-

Fluidized bed separator

-

Material:

-

Carbon Steel & Ceramic Liner

-

Color:

-

Customized Making

-

Application:

-

Coal Mining

-

Local Service Location:

-

Peru, India, Russia, Australia, South Africa

-

After-sales Service Provided:

-

Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

ISO

Product Description

FBS Fluidizing Bed Separator

FBS Fluidizing Bed Separator is one new-type separation equipment of self-generating medium, large capacity and low operation cost, which is developed by the cooperation between Weihai Haiwang Hydrocyclone Co., Ltd and Chinese Academy of Sciences Engineering Institute, who combined fluidized technology and gravity hindered settling separation technology for the turbulence field. It can realize the highly efficient separation or purification of coarse coal slime, mining sands, pyritic etc. fine particles. As the technical achievement verification of Shandong Province, it has reached domestic leading technical levels and has been listed as the major energy-consumption technical industrial project of Shandong province and National torch planning project successively, which is also entitled with two national practical new-type patents and one award of scientific and technological progress in Shandong province.

FBS Fluidizing Bed Separator is one new-type separation equipment of self-generating medium, large capacity and low operation cost, which is developed by the cooperation between Weihai Haiwang Hydrocyclone Co., Ltd and Chinese Academy of Sciences Engineering Institute, who combined fluidized technology and gravity hindered settling separation technology for the turbulence field. It can realize the highly efficient separation or purification of coarse coal slime, mining sands, pyritic etc. fine particles. As the technical achievement verification of Shandong Province, it has reached domestic leading technical levels and has been listed as the major energy-consumption technical industrial project of Shandong province and National torch planning project successively, which is also entitled with two national practical new-type patents and one award of scientific and technological progress in Shandong province.

Specification

|

Specification

|

FBS1500

|

FBS1800

|

FBS2100

|

FBS2400

|

FBS3000

|

FBS3600

|

|

Dia. (mm)

|

1500

|

1800

|

2100

|

2400

|

3000

|

3600

|

|

Max O.D. (mm)

|

2240

|

2500

|

2800

|

3200

|

3800

|

4400

|

|

Capacity (t/h)

|

20~40

|

30~50

|

50~70

|

70~90

|

100~120

|

120~170

|

|

Bed density (g/cm³)

|

1.1~1.8

|

1.1~1.8

|

1.1~1.8

|

1.1~1.8

|

1.1~1.8

|

1.1~1.8

|

Product details

Technical Features

1. FBS fluidizing bed separator is the patented products from Haiwang Company, which is equipped with patented new-type underflow discharge valve;

2. Adopt the KOSO second generation electro-hydraulic actuator with higher positioning accuracy and oil limitation alarm function, which is more reliable with the protection grading of IP65, higher safety coefficient, power of only 150w and low energy consumption.

3. With the E+H high accuracy density sensor, the sensor protection grade is IP 68 with higher safety coefficient; the bed layer density can be accurate till 0.001g/cm3 so as to realize the density control of high accuracy.

4. SIEMENS PLC programmable controller: indicator mathematically speed reaches 0.22μs, which helps the signal collection, analysis and execution to be more convenient so as to guarantee the high accuracy separation of system.

5. Low water supplementary volume: the water supplementary volume for the separator per unit is only 10~15m3/m2•h.

6. Intelligent expert control system: adopt the intelligent expert control system, which can realize the automatic control and adjustment of FBS coarse coal slime separator during the production process; Equip ith the mobile phone intelligent APP for whole course monitoring function so as to help the real-time master and understanding of site managing people on the production situation and operation parameter of FBS coarse coal slime separator.

7. Underflow valve with patented structure: the underflow valve keeps the perpendicular linear movement inside of valve base without shaking from left to right; wearing resistant stainless material with the service life of over 6 months; maximum passing particles of 6mm, the underflow valve is not easily to get blocked and while the closing, the sealing performance is good.

2. Adopt the KOSO second generation electro-hydraulic actuator with higher positioning accuracy and oil limitation alarm function, which is more reliable with the protection grading of IP65, higher safety coefficient, power of only 150w and low energy consumption.

3. With the E+H high accuracy density sensor, the sensor protection grade is IP 68 with higher safety coefficient; the bed layer density can be accurate till 0.001g/cm3 so as to realize the density control of high accuracy.

4. SIEMENS PLC programmable controller: indicator mathematically speed reaches 0.22μs, which helps the signal collection, analysis and execution to be more convenient so as to guarantee the high accuracy separation of system.

5. Low water supplementary volume: the water supplementary volume for the separator per unit is only 10~15m3/m2•h.

6. Intelligent expert control system: adopt the intelligent expert control system, which can realize the automatic control and adjustment of FBS coarse coal slime separator during the production process; Equip ith the mobile phone intelligent APP for whole course monitoring function so as to help the real-time master and understanding of site managing people on the production situation and operation parameter of FBS coarse coal slime separator.

7. Underflow valve with patented structure: the underflow valve keeps the perpendicular linear movement inside of valve base without shaking from left to right; wearing resistant stainless material with the service life of over 6 months; maximum passing particles of 6mm, the underflow valve is not easily to get blocked and while the closing, the sealing performance is good.

Packing & Delivery

Packages for cyclones are made of fumigant-free plywood. The overall packaging will ensure to be firm, so that the product can be protected well without damage.

Company Profie

Established in 1989, Weihai Haiwang Hydrocyclone Co., Ltd. is the largest and leading supplier of cyclone separation equipment and technical service in the Asia-Pacific region, and also one of the world-renowned cyclone manufacturers. Haiwang’s leading products such as cyclone, classifying screen and separator etc. are widely used in mining, coal mining, electric power and environmental protection industry etc. Haiwang products take the leading market share in the field of separation industry and have been exported to more than 50 countries & regions including Australia and Russia etc. We have established the international branch companies including Neptune Mineral Co., Ltd in Russia and Helicon Mining Services Pty Ltd in Australia, and also the agencies in America, Peru, Chile, South Africa and India etc., thus to provide local service for clients all over the world conveniently. Haiwang has its own manufacturing bases, which cover an area of more than 150,000 square meters, the industry-leading manufacturing capacity and the standard production line equipped with the robot, laser cutting machine, automatic painting line etc. advanced machining equipment, competent of meeting the European, the American and the other international fabrication standards. The annual capacity is over 20,000 sets of different sizes of cyclones, more than 5,000 sets of vibrating screens and separators etc. In addition, Haiwang has the spare part warehouse with an area of more than 20,000 square meters, which can guarantee the timely and fast supply of various spare parts to clients. Haiwang has passed the EU CE certification, Quality Management System ISO9001, Environmental Management Systems ISO14001, Occupational Health & Safety Management System OHSAS18001 and GOST Russian authentication, which is a national safety production standardized enterprise.

Certifications

Hot Searches