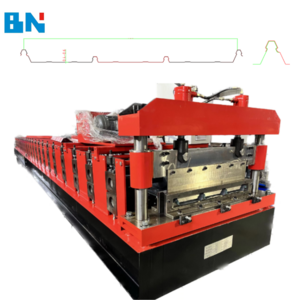

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V

-

Weight:

-

6500 kg

-

Feeding width:

-

1220mm or customized

-

Advantage:

-

Easy installation and operation

-

Roll material:

-

45# high grade steel

-

Frame material:

-

350 H-high grade steel

-

Way Of Drive:

-

Double chain and gear

-

Cutting blade material:

-

Cr 12 high grade steel

-

Cutting type:

-

hydraulic cutting

-

Lanugage system:

-

As client request

-

Feature:

-

high speed, low energy consumption

-

Control system:

-

PLC(detla) System

-

Profiles:

-

customized

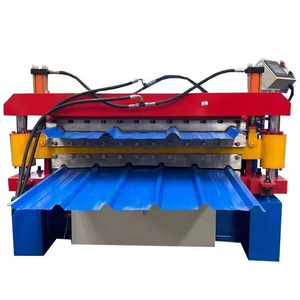

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V

-

Weight:

-

6500 kg

-

Feeding width:

-

1220mm or customized

-

Advantage:

-

Easy installation and operation

-

Roll material:

-

45# high grade steel

-

Frame material:

-

350 H-high grade steel

-

Way Of Drive:

-

Double chain and gear

-

Cutting blade material:

-

Cr 12 high grade steel

-

Cutting type:

-

hydraulic cutting

-

Lanugage system:

-

As client request

-

Feature:

-

high speed, low energy consumption

-

Control system:

-

PLC(detla) System

-

Profiles:

-

customized

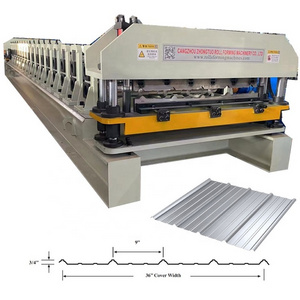

Product Description

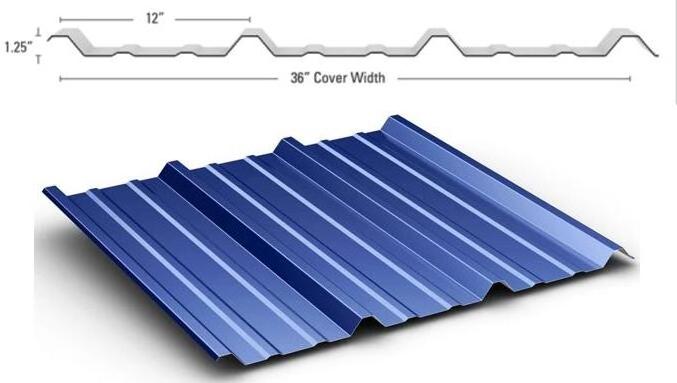

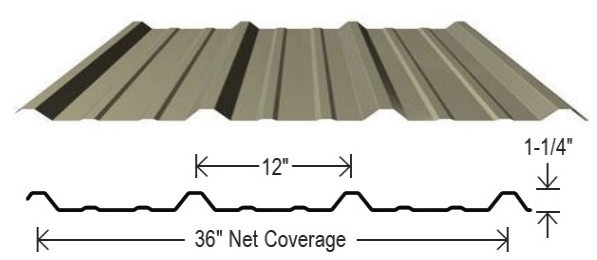

USA popular

roofing sheet making machine

PBR panel R panel Roll Forming Machine

USA popular PBR panel Roll Forming Machine R panel Roll Forming Machine roofing sheet making machine

hot sale to US,as R panel,.Ag panel and PBR panel hot sale

.It is a machine to produce building material of metal roof.

Stable Transmission : Gear box transmission

Strong structure

: Casting iron brand structure

Full Automatic Easy Operation : Whole producing line just need one person for operation. PLC control system control the machine speed, length and quantity.

Full Automatic Easy Operation : Whole producing line just need one person for operation. PLC control system control the machine speed, length and quantity.

Will also give you a remote control for easy operate.

Hydraulic per cutter

Hydraulic per cutter

Application of the finished product showing

Processing Flow

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving table

|

USA popular PBR panel Roll Forming Machine R panel Roll Forming Machine roofing sheet making machine

|

|

|

|

|

||||

|

1.Formed Material

|

PPGI,PPGL

|

|

Material Thickness:24/26 Gauge (0.3-0.6 mm)

Width:43inch(1092mm)

|

|

||||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

|

Manual decoiler(will give you as free)

|

|

||||

|

3.Main body

|

Roller station

|

|

18 rows(As your requirement)

|

|

||||

|

|

Diameter of shaft

|

|

80mm solid shaft

|

|

||||

|

|

Material of rollers

|

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|

||||

|

|

Machine body frame

|

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|

||||

|

|

Drive

|

|

gear and Double Chain transmission

|

|

||||

|

|

Dimension(L*W*H)

|

|

9.5m*1.65m*1.5m

|

|

||||

|

|

Weight

|

|

7.5T

|

|

||||

|

4.Cutter

|

Automatic

|

|

cr12mov material, no scratches, no deformation

|

|

||||

|

5.Power

|

Motor Power

|

|

7.5KW

|

|

||||

|

|

Hydraulic system power

|

|

4.5KW

|

|

||||

|

6.Voltage

|

380V 50Hz 3Phase

|

|

As your requirement

|

|

||||

|

7.Control system

|

Electric Box

|

|

Customized(famous brand)

|

|

||||

|

|

Language

|

|

English(Support multiple languages)

|

|

||||

|

|

PLC

|

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|

||||

|

18.Forming Speed

|

15-20m/min

|

|

The speed is adjustable

|

|

||||

Products Display

5T Manual Decolier For Free

Capacity:5 tons

Coil inner diameter:450-550mm Feeding width: max 1220mm Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine

Feeding Device

1.Hand wheels on both sides can be used to adjust the feeding width. 2.Four stainless rollers can make the material go into the

machine smoothly and prevent the scratch on the material surface. 3.There are three rows of orange plastic rollers can make the

steel coil go into the machine smoothly.

machine smoothly and prevent the scratch on the material surface. 3.There are three rows of orange plastic rollers can make the

steel coil go into the machine smoothly.

Roll Forming And Transmission Device

1.rollers thick chromed good hardness for long service time.

2. Each roller has number and with keynotes, it can fix on the shaft

stablely

3.gear and double chain,stable

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider ●Operating

language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is

really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor: 5.5 KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of

hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

Recommend Products

Why Choose Us

USA Customer case

Hot Searches