- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

49

-

Place of Origin:

-

America / Germany

-

Application:

-

seawater desalination

-

Grade:

-

Nickel alloy NAS 254NM

-

Ni (Min):

-

24.29

-

Model Number:

-

Nickel alloy NAS 254NM-1

-

Brand Name:

-

SMC,ATI

-

Product name:

-

UNS N08367

-

Technique:

-

hot / cold rolled

-

Surface:

-

No.1 / 2B

-

Length:

-

100 - 12000mm

-

Width:

-

200 - 20000mm

-

Thickness:

-

0.5 - 150mm

-

Packing:

-

steel frame / woven bag or as per the client request

-

origin:

-

USA / Germany

Quick Details

-

Resistance (μΩ.m):

-

LOW

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

770

-

Elongation (≥ %):

-

49

-

Place of Origin:

-

America / Germany

-

Application:

-

seawater desalination

-

Grade:

-

Nickel alloy NAS 254NM

-

Ni (Min):

-

24.29

-

Model Number:

-

Nickel alloy NAS 254NM-1

-

Brand Name:

-

SMC,ATI

-

Product name:

-

UNS N08367

-

Technique:

-

hot / cold rolled

-

Surface:

-

No.1 / 2B

-

Length:

-

100 - 12000mm

-

Width:

-

200 - 20000mm

-

Thickness:

-

0.5 - 150mm

-

Packing:

-

steel frame / woven bag or as per the client request

-

origin:

-

USA / Germany

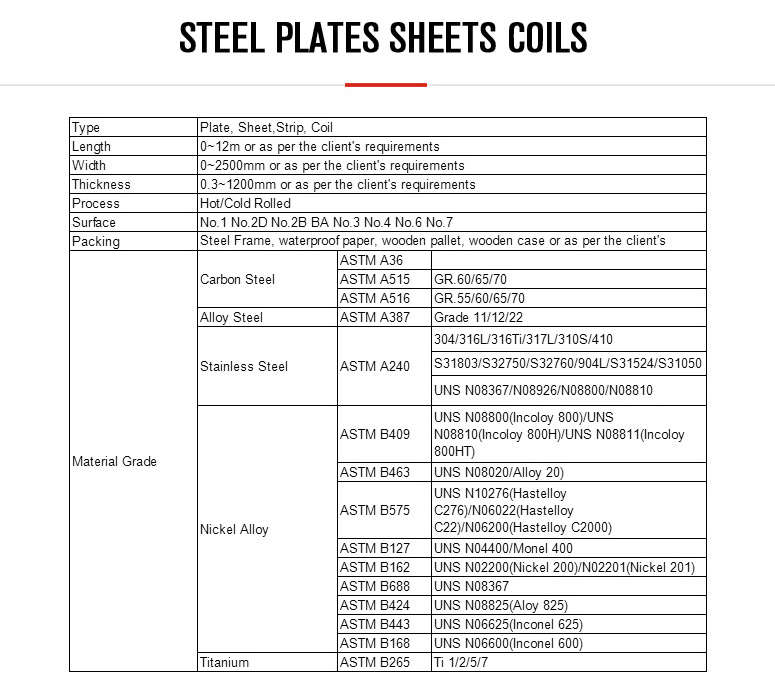

Competitive price Nickel alloy NAS 254NM Cold Rolling Steel Coil,sheet,and plate Supplier

INCOLOY alloy 25-6HN is a 6% molybdenum super-austenitic stainless steel. It offers an excellent combination of strength, ductility and resistance to corrosion by a variety of media at an economical price. It is readily formed and welded. The properties of the alloy are enhanced by its content of nitrogen. Its high content of nickel results in thermal stability and resistance to stress corrosion cracking. Designated as UNS N08367, alloy 25-6HN directly competes with Allegheny Ludlum alloy AL6XN®. The alloys are covered by the same ASTM, ASME, and NACE specifications. Applications are found in the air pollution control, power, chemical processing, marine, pulp and paper, and oil and gas industries. Alloy 25-6HN is a new addition to Special Metals existing line of high performance, super-austenitic stainless steels, INCOLOY alloys 25-6MO and 27-7MO.

Characteristics

- PREN 48.3 Typical for ASTM G48, CPT per G48-C 75C, CCT per G48-D 35C

- Density 0.290 Lbs/cubic inch

- Magnetic permeability 1.003 (200 Oersteds at Room Temp)

- Coefficient of thermal expansion (68-212F) 8.49x10 in/in Deg F

-

Higher strength than conventional austenitic grades (304/316)

Applications

- Marine enviroments

- Desalination systems

- Flue gas desulfurization equipment

- Reaction vessels for pharmaceutical production

Chemistry

Chemical Requirements |

||||||||

|---|---|---|---|---|---|---|---|---|

|

Ni |

C |

Mn |

Cr |

N |

Si |

Mo |

Fe |

|

|

Max |

25.5 |

.03 |

2.0 |

22.0 |

0.25 |

1.0 |

7.0 |

Bal |

|

Min |

23.5 |

20.0 |

0.18 |

6.0 |

Tensile Data

Mechanical Property Requirements |

|||||

|---|---|---|---|---|---|

|

Ultimate Tensile |

Yield Strength (0.2% OS) |

Elong. in 2 in. or 50mm or 4D, min., % |

R/A |

Hardness |

|

|

Annealed |

|||||

|

Typical |

107 KSi |

55 KSi |

48 |

Rb 90 |

|

D- Forging quality is furnished to chemical requirements and surface inspection only. No mechanical properties required.

Specifications

|

Form |

Standard |

|---|---|

|

Metal Type |

UNS N08367 |

|

Bar |

ASTM B691 / ASME SB691 |

|

Wire |

ASTM B691 / ASME SB691 |

|

Sheet |

ASTM B688, A240 / ASME SB688 SA240 |

|

Plate |

ASTM B688, A240 / ASME SB688 SA240 |

|

Tube |

ASTM B676 WELDED |

|

Pipe |

ASTM B675 WELDED |

|

Fitting |

ASTM B366 / ASME SB366 / ASTM B462 / ASME SB462 |

|

Forging |

ASTM B472 / ASTM B462 / ASME SB462 |

|

Weld Wire |

622, 686 or 625 |

|

Weld Electrode |

Inconel 112, 122 or INCOWELD 686CPT |

|

Din |

|

Machining

| MACHINING DATA | |

|---|---|

|

Carbide tools are suggested

For Rates Better Than 50% Of Type 304. |

|

| Machining Type | Suggested starting rates are: |

| Single Point Turning : |

Roughing - 0.15" depth, 0.018"/rev feed -200 SFM

Finishing - 0.025" depth, 0.007"/rev feed - 350 SFM |

| Drilling : |

1/4" Dia hole - 0.004"/rev feed - 60 SFM

1/2" Dia hole - 0.007"/rev feed - 60 SFM 3/4" Dia hole - 0.010"/rev feed - 60 SFM |

| Reaming : | Feed - same as drilling - 100 SFM |

| Side And Slot Milling : |

Roughing - 0.25" depth - 0.007"/tooth feed - 125SFM

Finishing - 0.050" depth - 0.009"/tooth feed - 140SFM |

|

These rates are for carbide tools,

Type C-2 For Roughing, Drilling And Reaming. Type C-3 For Finishing. |

|

INCOLOY® is a registered trademark of Special Metals.

Q:How does your factory do regarding quality control?

A:Quality is priority. we always attach great importance to quality controlling from the beginning to the end.

Mill Test Certificate is supplied with shipment. If needed, a Third Party Inspection is acceptable.

Q:May I have some samples before bulk order?

A:Yes, of course. samples are free but you have to pay the courier.

Q:Can we visit your Company?

A:Surely. Welcome to China and we will be honored to have a customer and friend.

Q:What is the payment terms?

A:T/T, L/C ,Western Union,etc.

Q:What's your delivery time?

A:For stocks, we can send the goods to loading port within 7 days after receiving your deposit.

For production period, it usually needs about 10days- 60days after receiving the deposit.

Q:Is it OK to mark my logo on your products?

A:Yes. OEM and ODM are available for us.